Happy Tuesday. Had some visitors this weekend an of course the trains decided to derail at two places, the swing door and the outer bridge loop. Swing door I understand, bridge… I have no idea what's going on.

Continue printing all sorts of stuff, some really good, some not-so-good. Still trying to perfect just how big small details have to be to have a chance of surviving my clumsiness. Thought I had a perfect engine back end and then knocked off one of the blower oil lines. I'm going to attempt to drill and replace with metal. I finished up five working lights for the engine house, primed them gloss black and then a darkened aluminum. I also started finish painting some of the other machine tools. I used foil with some PSA to simulate the slides and column. I painted the work table that darkened aluminum (to look like steel).

I wanted to air brush the metallic paint so I had to mask the whole deal.

Still some more details to paint and I have to add back a big hand wheel. I used my first separately printed hand wheel today to repair a good print of the surface grinder.

Here's a bunch of stuff that got primed including a successfully printed work bench with shelves. I thickened all the workbench members.

The lights are going to work okay. I got a big screwed up. Somewhere along the building process I switched from 2 inches to 3 inches on the length of the pole before the bend. I had two at 2 inches, one at one and half inches and two at 3 inches. I didn't think I could stretch one so I took one apart and cut it down to the two inches. I was able to get it apart by soaking it for a bit in acetone which softened the CA. Luckily, the resin is impervious to solvents.

After I got them all working and potted with Bondic I clipped the magnet wire short and spliced on heavier leads that will tie into the building electrics. At first I was using the heavier gauge black/red zip cord, but it was overkill. I wanted to be able to shrink tube all the way into the lamp base and the thick wire prevented it. So some are the heavier and the rest are thinner gauge.

Here they all are which the black primer. More masking since I wanted to maintain the shiny aluminum poles.

I'll take the final shot tomorrow. I'll also attempt to get them up and running. We're heading out for a long weekend to State College to see my youngest granddaughter staring in a professional production of Matilda. She's becoming one heck of a performer.

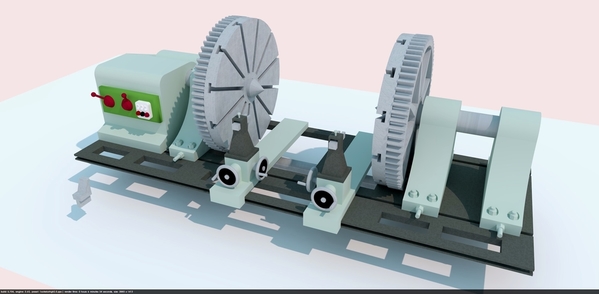

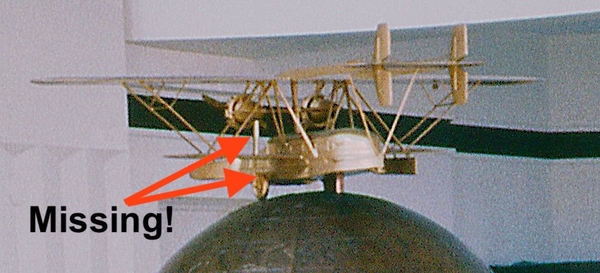

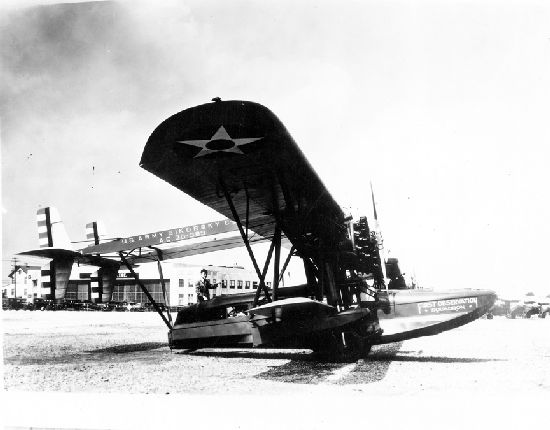

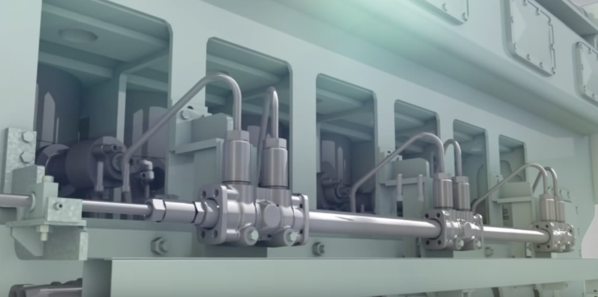

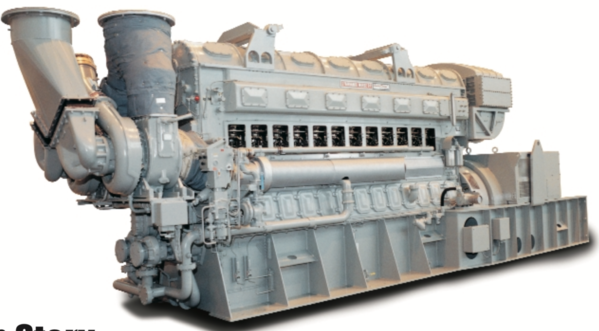

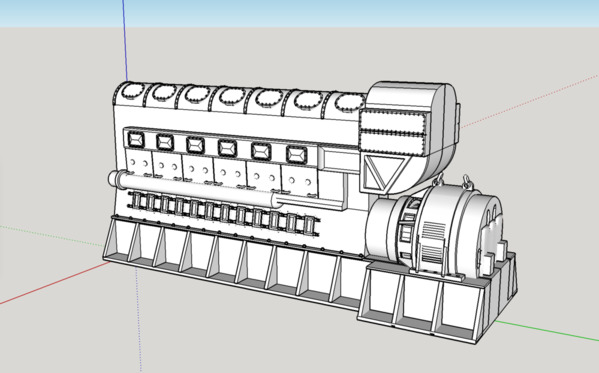

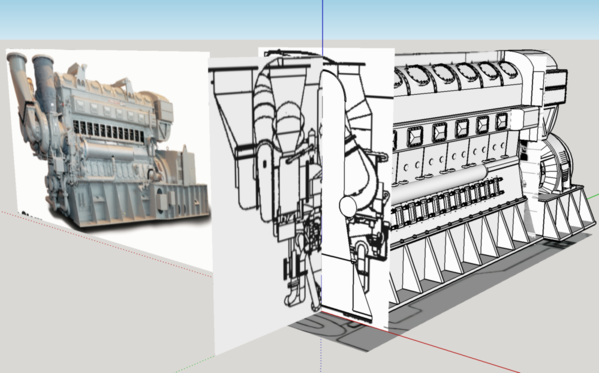

And I finished up my design for the wheel lathe. Couldn't find any pictures that really showed the entire machine. Furthermore the pictures I did find showed great complexity that would be hard to create. So I did a free lance design that incorporates all the essential things a wheel lathe has, but without the stuff that would be too fine to print anyway. The little gray part over the left is a chuck cleat that I will make at least 8 of to fit into those huge face plates. The cleats grab the inside of the driver's rim to rotate and stabilize them. The centers are into the driver's axle. I went with a solid-center hand wheel in hopes it can stay together. You can't see it, but underneath is a cross-shaft with pinion gears that engage both flywheels and the drive the right one from the left one which is tied to the motor. This is an old design dating back to the early 1900s. This is my SketchUp drawing rendered in Podium plug in.

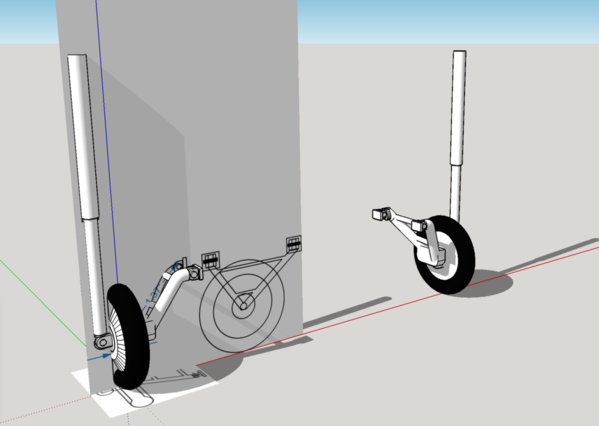

I'm printing it as a series of subassemblies. Two heads, two carriages, the base and the cross shaft. When I first loaded it all up on the slicer that resin use was quite high, then I realized that I didn't hollow out any of the heavier pieces. This wasn't as easy as it sounds since all those chunks on the left head are separate parts pushed together. When I hollowed out an upper part, I had to make and opening in the lower part so the uncured resin has a way out. it did reduce the volume of resin consumed. I'm not anticipating any printing problems since everything's pretty robust. Can't say that for the drill press I printed. First all the levers fell off, then the chuck and spindle fell off and finally the table fell off. There is a reason why really fine details are cast in brass using lost wax. Brass is probably 10X stronger than UV resin. Since part of the machined is below floor level I will have to cut the floor while it's all attached to the engine house. I can used the Dremel with a router head.