Yup, i dropped my Lionel JLC GG1 down the stairs yesterday. It was still in the box but no less shocking. Fortunately nothing was damaged

This is one of the few times I had something to share on the Forum, and my search revealed the same or similar topic, so I'm reviving this one.

Yesterday, my 7 year old grandaughter and I were each running a freight train pulled by an LC+ loco, each with our own remote unit, on separate main lines. We were having a great time doing that.

Unlike most young children running trains, my grandaughter was very content going nice and slow, occasionally blowing the whistle or ringing the bell. I was doing the same. Neither of us was racing our train. She ran hers flawlessly.

I decided to back up my oil tanker unit train into the siding to the right of the O22 switch on the right side in the photo below, leave the tanker cars in that siding, and have my LC+ Jersey Central Pacific Steamer pick up passenger cars on the other side of my layout.

Notice how close the track is to the edge of the table in the above photo. Also the O22 switch on the right, if thrown straight, leads to the siding where I was trying to park about 7 or 8 tanker cars; if thrown to the left curve, then the train would continue along the reverse loop.

The switch was thrown straight to back the tanker cars into the siding. The cars did not have enough clearance from the back wall, several cars derailed, and one tanker and the locomotive and tender fell off the table striking the concrete floor 4 feet (about 48 inches) below the table.

2 metal ladders were dislodged from one tanker car. I found them on the floor, and inserted them back on the car, so no harm done.

But my heart sunk when I saw one set of wheels on the floor that came off the tender. I examined the tender closely and noticed a small piece of plastic that I believe is supposed to be part of the journal box, had broken off. That broken piece of plastic holds the wheel axle and wheels in place. I frantically searched the floor for that small piece of plastic, and found it after about 10 minutes of searching for it.

I had some left over Loctite Superglue. I put the axle for the loose pair of wheels in each journal box, and put a tiny dab of superglue on the edge of the broken piece of plastic, put the axle and wheels back in the journal box, and pressed the glued broken pieces together.

I now have the tender on the track in another siding in the middle, not the edge, of the layout. I won't touch the tender for at least 24 hours to give the Superglue plenty of time to dry/set.

I have always known that my trains are in danger of falling off the table when running near the edge of the layout where the locomotive derailed and fell. I'm thinking of putting pillows on the floor there when running trains so if they fall off the table, it would be a soft, not hard, landing to minimize/eliminate damage.

What do you think?

Arnold

Attachments

Below is the follow up on LC+ loco that took a dive yesterday.

After letting the Superglue set for 15 hours, I decided to test my Scrounger's Blue Comet, the LC+ Jersey Central Pacific, this morning.

This is a very happy ending. I powered it up, heard the sounds (which were music to my ears), ran it 2 inches forward and backward, and everything is fine. Also, there are no chips, scratches, or other body damage, so the loco is unscathed from the fall. IMO, this is amazing considering the it fell 4 feet onto a concrete floor.

I will leave the tender on a siding for another approximately 8 hours to make sure the Superglue completely sets.

This particular LC+ loco, which is now my #1 in my collection, seems to be as rugged and reliable as its classic Postwar ancestors. LOL. Ruggedness and reliability are qualities I most cherish in my trains.

I feel like my Poor man's Blue Comet and I have dodged a bullet! Arnold

Arnold, my tracks also run close to the edge of my layout. I have a crossover on a straight section of the track where I also had a drop of 40 inches to concrete. My little 0-6-0 Gilbert switcher took that fall, it had damage to the headlight and little else when I ran into a turnout set out. I ended up adding a 1x2 around the layout with a rabbit cut to allow some clear flexible plastic to be set in to keep errant trains safe.

Ray

Been there done that. I was reaching over the layout to uncouple a car and my shirt sleeve caught my 0-6-0 Docksider on my elevated loop. I didn't even feel the tug on my shirt buy my heart sunk when I heard the loco hit the floor. Miraculously it must have landed perfect flat on its side.

The engineer took a tumble out of his chair and was checked out by paramedics on the scene and released. One of the side rods was slightly bent but no other damage otherwise. I'm much more careful now.

Attachments

In the aftermath of surviving the big dive, there is no question that it is wise to design the layout so the trains don't come to close to the edge of the platform. This is especially true for those with expensive engines like Visionline.

My layout is designed so there is room to do other things besides trains in the basement, some of which are necessities such as the laundry. LOL. Don't think I'm not grateful to be married to a woman who tolerates my insanity, which includes running trains within inches of her right elbow when she is loading dirty clothes into the washing machine! LOL

Since I like my trains going to different places, and space for them is modest, I will keep my layout design "as is," and consider having pillows on the concrete floor to cushion any potential fall. Arnold

Not dropped, but I launched this (undecorated) S Scale GP while test running it during its construction. It attempted an Evil Kenevil leap across my removed lift out section when I wasn't paying attention. I picked up the pieces and threw them into a box.

It was several years before I worked up the ambition to put the pieces back together and finish the project.

Rusty

Attachments

Lift-outs are a recipe for disaster.

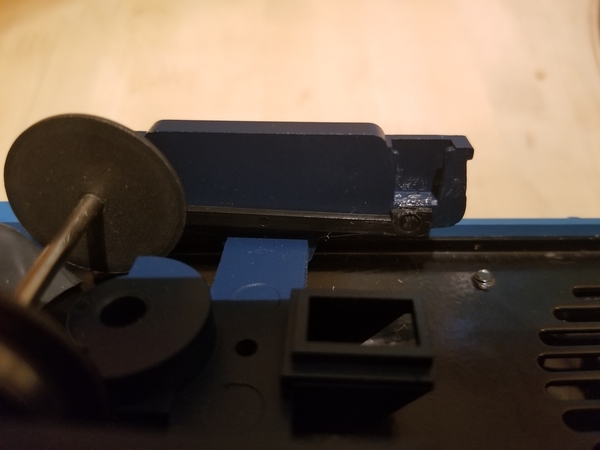

After an early near-disaster I fail-safed it:

That is a Maytag dryer door switch seen here in it's normally open position, cutting off 120VAC power to the layout. Putting the lift-out in place depresses the button which supplies juice to the layout. Quick, simple and cheap.

Attachments

My brother and I had "train races" and would roar with laughter watching the engine (steam) going off the rails on a curve. And hitting the bare concrete floor. Not so funny now....but I admit I still chuckle a bit thinking about the trials.....and after the launching, the postwar engines always seemed to run.

Lew that’s a great safety feature and surly a necessity as a fail safe as we certainly get tunnel vision when we are operating or troubleshooting a problem.

Arnold D. Cribari posted:I have always known that my trains are in danger of falling off the table when running near the edge of the layout where the locomotive derailed and fell. I'm thinking of putting pillows on the floor there when running trains so if they fall off the table, it would be a soft, not hard, landing to minimize/eliminate damage.

What do you think?

Arnold

The problem I see with pillows is that they'd have gaps between them. And the universe being what it is, the falling locomotive would inevitably roll into the nearest gap and meet the floor.

I had a similar experience when I was only seven years old. I decided to see how fast my 2026 could go around its 027 curves. I found out, when it launched itself from the rails, off the layout, and rolled across our living-room floor.

Mitigating my foolishness was the fact that our Christmas train layout was only about eight inches off the floor. But the real lifesaver was our living-room braided carpet. The 2026 rolled across it over and over, scaring the pants off my seven-year-old self but doing no damage whatever. It was completely unharmed, and sits on our coffee table today, in honored retirement.

My point in confessing to this youthful folly is that whatever kind of padding you put on the floor under your layout should be firm enough to absorb the momentum of any falling trains without harming them -- and that there should be no gaps into which the trains can fall or roll.

Of course, the real answer is to catch the errant trains before they fall, preferably with a wire-mesh or plexiglass fence around the layout's edges. And if I am ever able to scrounge up the space for an elevated layout of my own, that's what I intend to do.

Oh, and by the way, I learned my lesson from that experience with the 2026. Never again did I run a locomotive too rapidly through a curve. And I've been obsessively careful about letting anything fall ever since. Near the beginning of this thread, I posted an experience I had when I let that caution slip for just a few seconds. Never again.

Wow, it's hard to believe this thread is really so old. Where did the time go?

All very interesting comments.

I agree that normal pillows we rest our heads on in bed may not provide enough protection for a falling loco.

I have an old sectional couch in my basement. It's the one my 7 year old granddaughter dances around on when she runs LC+ locos with the remote, that can be seen in a few of the videos I previously posted on other threads. I can take a couple of the couch cushions off and put them on the concrete floor beneath the layout edge.

Problem is my whole layout has track on the edges of 35 plus feet of plywood tables.

Maybe gerryrigging some mesh just beneath the layout edges is the answer for me down the road. In the meantime, I will be very careful running trains. Arnold

When my oldest son was about 4 we managed to accidentally launch Thomas off the table at about warp 3 going around a curve. 3 ft down to a solid floor. Primary damage was a broken coupler. My son still talks about it.

This video was taken about an hour after my Williams By Bachman B&O E-7 dropped about 3 feet after I accidentally left the walk thru on our clubs layout open to test run it. Luckily it landed right and the only damage was one of the pickup rollers got bent back which was an easy fix.

Arnold D. Cribari posted:All very interesting comments.

I agree that normal pillows we rest our heads on in bed may not provide enough protection for a falling loco.

I have an old sectional couch in my basement. It's the one my 7 year old granddaughter dances around on when she runs LC+ locos with the remote, that can be seen in a few of the videos I previously posted on other threads. I can take a couple of the couch cushions off and put them on the concrete floor beneath the layout edge.

Problem is my whole layout has track on the edges of 35 plus feet of plywood tables.

Maybe gerryrigging some mesh just beneath the layout edges is the answer for me down the road. In the meantime, I will be very careful running trains. Arnold

Pillows? Furniture?

No.

They invented plexiglas for model RR layouts; a well-kept secret.

Some months ago; work in progress - adding on to turntable whisker tracks (I moved the workbench). The edges of my layout are protected by this stuff. The piece of wood is there because I ran out of plexiglas. Thin wood (I often use old paneling, ripped appropriately) at the edge of your layout, even if it only rises 2 inches above the layout top, will prevent 99% of all loco diving.

Attachments

Attachments

I know stuff like this happens! But is guess I have learned how to do preventative measures with my postwar trains.

I run multiple reverse loops on 031 tubular curves right at the very edge of the tables that is 4 tight curved edged areas. I Run all my postwar engines without worry. How? Banked curves. Not only do the trains look good leaning into the curve, they don't derail. Most have magnatraction, an added plus. I try not to run trains not max speed. My locos like 031 at edge of tables. I was thinking I would need some kind of barrier fence at tables edge, NOPE, not one near miss has occurred, I do have rubber floor matting around my layout for foot comfort. No derailments (yet). 2020, 2055, 736 are OK with banked curves. All my electrics and diesels from corporation days are still intact too. I used flexible H O scale cork roadbed inserted a quarter of the tie length and fastened the insertion side of tie with a track screw. I intended to glue down the cork but hav not needed to.

However on a switching layout i did have a disaster with a particularly hard to fine two rail atlas RS -1. My finally obtained Loco was on a siding and I got distracted, left the power up, and threw the turnout , power went LIVE and By the time I killed the power it took out a bumper at the tables edge and dangled on the edge of table me running 30 feet to see it go down 55 inches to the concrete floor! Well I certainly learned about edges and shoulder heights sooner or later. Atlas fixed the engine without cost ( under warranty) and I placed an emergency power kill switch at several points in the layout ( it was 37 feet long). Plus those three bumpers were fortified with screws and inch sticking up behind bumpers for inadvertent high speed runaways! Never again, safety first!

Back in the NYC apartment days, I once had a point to point 8x 1.5 switching layout with fortified plexiglass at either end.

but another runaway postwar Geep took out the plexiglass! But it did hit the wall.

i remember my wife saying at least it didn't go out the window (very close to end of plexiglass). It was a straight shot to the wall. And besides regardless of the five flights up, the fire escape would have saved it. Lol.

No freight was lost.

This is a two ended question, do you mean purposely or accidentally? Those who have had accidents, in most cases, are testimony to the strength of this scale. You can actually have a fall and recover with minimal repairs needed. I believe the despair and guilt that is felt after this happens is the most damaging part of an incident of the sort.

Dave

Arnold,

Sorry to hear of the calamity. I hope it does not dissuade your granddaughter from running trains.

My New Haven RS-3 #531 sometimes used to be parked on the stub track at the front corner of my layout. Careful as I am, I once brushed against it and it fell 48 inches to the carpeted concrete floor, breaking the front pilot in two. Atlas O had the part so it got fixed as well as new. Tracks are close to the edges of both my layouts. But it’s more likely that I could drop something while moving between shelf and track.

Photo by:

MELGAR

Attachments

Arnold D. Cribari posted:

But my heart sunk when I saw one set of wheels on the floor that came off the tender. I examined the tender closely and noticed a small piece of plastic that I believe is supposed to be part of the journal box, had broken off. That broken piece of plastic holds the wheel axle and wheels in place. I frantically searched the floor for that small piece of plastic, and found it after about 10 minutes of searching for it.

I had some left over Loctite Superglue. I put the axle for the loose pair of wheels in each journal box, and put a tiny dab of superglue on the edge of the broken piece of plastic, put the axle and wheels back in the journal box, and pressed the glued broken pieces together.

I now have the tender on the track in another siding in the middle, not the edge, of the layout. I won't touch the tender for at least 24 hours to give the Superglue plenty of time to dry/set.

I believe the part that broke off is a AXLE BEARING / PLASTIC / PILOT / TRAILING TRUCK 6208616339

https://www.lionelsupport.com/...;submitButton=Search

I find it handy to have spares of these on hand.

An Atlas SW9 that belonged to another forum member. $100 purchase, patience, new windows, from Atlas, and glue.

I was thinking a little brush painting and a grimmy black over-spray. That hasn't happen yet, a conversation piece.

Crash model, be sure to save all the pieces.

Last week a bookcase shelf collapsed and took my CC KLine New Haven EP-5 with it. One of the cast truck side frames shattered.

Peter

Mike CT posted:An Atlas SW9 that belonged to another forum member. $100 purchase, patience, new windows, from Atlas, and glue.

I was thinking a little brush painting and a grimmy black over-spray. That hasn't happen yet, a conversation piece.

Crash model, be sure to save all the pieces.

Way-back-when I knew a guy who had a body shop. He specialized in Corvettes. When he got the wrecker call he always brought along a couple helpers with a pickup truck, shovels and brooms. They would be sure to sweep up all the pieces of broken fiberglass and haul it all back to the shop where George would start laying out the pieces. Then he'd slowly reassemble the crushed fiberglass body work using epoxy resin, the stuff the panels were made with at the factory. His bodywork was so smooth no customer ever complained and that is why the adjusters were willing to pay for new panels and George got to pocket that money. George was quite good at it.

Davety posted:Arnold D. Cribari posted:

But my heart sunk when I saw one set of wheels on the floor that came off the tender. I examined the tender closely and noticed a small piece of plastic that I believe is supposed to be part of the journal box, had broken off. That broken piece of plastic holds the wheel axle and wheels in place. I frantically searched the floor for that small piece of plastic, and found it after about 10 minutes of searching for it.

I had some left over Loctite Superglue. I put the axle for the loose pair of wheels in each journal box, and put a tiny dab of superglue on the edge of the broken piece of plastic, put the axle and wheels back in the journal box, and pressed the glued broken pieces together.

I now have the tender on the track in another siding in the middle, not the edge, of the layout. I won't touch the tender for at least 24 hours to give the Superglue plenty of time to dry/set.

I believe the part that broke off is a AXLE BEARING / PLASTIC / PILOT / TRAILING TRUCK 6208616339

https://www.lionelsupport.com/...;submitButton=Search

I find it handy to have spares of these on hand.

Davety, thank you for that info, which I may need if the Superglue does not work long term. Arnold

When my younger son was about eight years old, he tried to prove that GG1s could fly! Well, they do, for just a second or two. My 2332 left the table at full speed and landed on its side on the concrete basement floor.....not a scratch! I was thankful that my precious Madison cars weren't attached. We laugh about it now, especially since my son now has children and sure enough they too like to fly a train or two.

Earl

I’ve never dropped one, but like John Pignatelli, I did throw one across the room. I was a kid, maybe 8 years old. We had a 4X8 HO layout in the basement and my big brother would not let me run the trains even after what seemed like an eternity of pleading. Out of frustration, I grabbed a loco and threw it across the room. When my dad got home, I got a wuppin and was not allowed to run the trains at all.

Davety posted:Arnold D. Cribari posted:

But my heart sunk when I saw one set of wheels on the floor that came off the tender. I examined the tender closely and noticed a small piece of plastic that I believe is supposed to be part of the journal box, had broken off. That broken piece of plastic holds the wheel axle and wheels in place. I frantically searched the floor for that small piece of plastic, and found it after about 10 minutes of searching for it.

I had some left over Loctite Superglue. I put the axle for the loose pair of wheels in each journal box, and put a tiny dab of superglue on the edge of the broken piece of plastic, put the axle and wheels back in the journal box, and pressed the glued broken pieces together.

I believe the part that broke off is a AXLE BEARING / PLASTIC / PILOT / TRAILING TRUCK 6208616339

https://www.lionelsupport.com/...;submitButton=Search

I find it handy to have spares of these on hand.

Hi Davety and any other Forum mechanical whizzes out there. I can really use your help, as explained below.

A couple of days ago, I posted here that my beloved LC+ Jersey Central Pacific #832 Steamer and tender (#6-84680) took a 4 foot dive off the train table, onto the concrete floor, and a piece of black plastic the holds a wheel axle for the tender broke. I found the broken piece of plastic and used Loctite Superglue to put the piece of plastic and wheel axle back together.

I let 2 full days go by, and ran the engine this evening. Everything was fine until I took the engine and tender off the track, and as I did that, the wheel fell off, and now I can't find that plastic part.

I can't thank Davety enough for his above reply identifying that plastic part (axle bearing part # 620-8616-339) and providing the link for me to order it from Lionel, which I just did.

Now, I have a couple of questions.

Once I get the replacement part, how do I affix it so it properly holds the wheel axle in place?

I assume that this axle bearing is glued in place. If so, what is the best glue for me to use, where can I buy it, and how long should I let the glue set to maximize the chances it will work?

Arnold

Hi Bob, yes I did. A Lionel Alleghany took a tumble four feet to the concrete floor. Landed on it's wheels. It was ugly buddy. ![]() Lionel repaired it for me at the behest of my dealer Lou Caponi, back when he was still with us.

Lionel repaired it for me at the behest of my dealer Lou Caponi, back when he was still with us.

I still have it, but I did install a Plexiglas barrier. ![]()

No, but I did drop the thanksgiving turkey once and the international consequences were horrific - the downfall of Turkey, the breaking up of China, and the overrun of Greece....sorry about that ...![]()

Hi Arnold, I just read your post and boy at lest I'm not the only butter finger in the group.

Try to hook up with Gunrunner John. He is really good at this sort of things.

Don't feel bad, in my case all the drive wheels flanges where bent along with the axels.

Now, I'm not sure if the part posted by Davety above, is the correct part.

This is a photo of the damaged part (on right side of the photo) showing a small piece of plastic that broke off and is now missing:

Below is a photo of the undamaged part on the opposite side of the truck:

As shown above, the whole part extends over the top inside of the truck and holds both wheel axles in place.

Arnold

Attachments

Arnold,

That should be the correct part. The photo from Lionel's site isn't very good. That extra piece of plastic out to the side is the clip that holds it in place. In your photo that part would go down, towards the body of the tender and clip in thus holding the wheel axle in place.

Davety posted:Arnold,

That should be the correct part. The photo from Lionel's site isn't very good. That extra piece of plastic out to the side is the clip that holds it in place. In your phone that part would go down, towards the body of the tender and clip in thus holding the wheel axle in place.

Davety, is any glue used to hold that part in place and/or the black plastic part that extends on the top inside of the truck in place?

I just noticed that the part that extends on the top inside of the truck is loose on my tender truck.

I think I may also need to order the clip that holds the axle bearing in place. Davety, Gunrunner, or other repair expert, do you know the part number for that clip, and how to attach it to the truck?

By the way, it looks to me that the axle bearing and clip that extends on the inside and top of the truck is one part, not 2 separate parts, on this LC + tender. Arnold

Arnold D. Cribari posted:Davety posted:Arnold,

That should be the correct part. The photo from Lionel's site isn't very good. That extra piece of plastic out to the side is the clip that holds it in place. In your phone that part would go down, towards the body of the tender and clip in thus holding the wheel axle in place.

Davety, is any glue used to hold that part in place and/or the black plastic part that extends on the top inside of the truck in place?

I just noticed that the part that extends on the top inside of the truck is loose on my tender truck.

That part has the clip attached, no glue needed. From your picture it appears that the clip part of the axle bearing piece may still be attached to your truck. Here's a picture from the parts site of the top of your truck. noticed the cutouts near the wheels. This is where the clip part of the axle bearing clips in. If you need to remove the wheels for some reason you would put a small screwdriver in there and gently pull the clip away from the truck toward the wheels and push down to get the wheel set out. I wish I could find a video showing all of this, but am unable to do so.

Davety posted:Arnold D. Cribari posted:Davety posted:Arnold,

That should be the correct part. The photo from Lionel's site isn't very good. That extra piece of plastic out to the side is the clip that holds it in place. In your phone that part would go down, towards the body of the tender and clip in thus holding the wheel axle in place.

Davety, is any glue used to hold that part in place and/or the black plastic part that extends on the top inside of the truck in place?

I just noticed that the part that extends on the top inside of the truck is loose on my tender truck.

That part has the clip attached, no glue needed. From your picture it appears that the clip part of the axle bearing piece may still be attached to your truck. Here's a picture from the parts site of the top of your truck. noticed the cutouts near the wheels. This is where the clip part of the axle bearing clips in. If you need to remove the wheels for some reason you would put a small screwdriver in there and gently pull the clip away from the truck toward the wheels and push down to get the wheel set out. I wish I could find a video show all of this, but am unable to do so.

Very helpful, Davety, thank you. Good news that no gluing is necessary.

Correct me if I'm wrong, but does that part, which consists of the clip and axle bearings, snap (or clip) into place?

Is another option to buy the whole truck, which would obviously be more expensive? If so, does that make the repair simpler?

The truck with the broken piece of plastic is the front truck of the tender. The all important tether, between tender and engine, is involved with that truck so great care is necessary in possibly replacing that truck.

The reason I am so interested (and a bit obsessive) about this repair is that this engine and tender is my very favorite in my collection, and I have a lot of engines collected over the past 65 years. Arnold

Arnold D. Cribari posted:Very helpful, Davety, thank you. Good news that no gluing is necessary.

Correct me if I'm wrong, but does that part, which consists of the clip and axle bearings, snap (or clip) into place?

I'd say that it snaps into place.

Is another option to buy the whole truck, which would obviously be more expensive? If so, does that make the repair simpler?

You could purchase the whole truck, that part is available. However that would be like replacing the entire wheel and axle assembly on your car because you need new wheel bearings. That would be the more expensive option. I think the simple repair would be to purchase just the axle bearing.

The truck with the broken piece of plastic is the front truck of the tender. The all important tether, between tender and engine, is involved with that truck so great care is necessary in possibly replacing that truck.

If you want to replace the entire truck, then yes you need to be careful of the wires and the draw bar if it's attached as part of the truck mounting to the tender. Some are and some aren't, I don't know you exact model to know for sure.

The reason I am so interested (and a bit obsessive) about this repair is that this engine and tender is my very favorite in my collection, and I have a lot of engines collected over the past 65 years. Arnold

For me it was a kick to the floor. I had my Lionel Percy on the dresser next to my bed and my foot got him and he landed on the hard floor. As the narrator from the show would say, "Luckily, no one was hurt." It woke me up and I checked him out; nothing broken or scratched and still runs. I have since put him in a storage tub along with the rest of my collection for protection from a furry pest...

I knocked my Lionel Mohawk #3000 off the edge of my layout to the concrete floor a couple of years ago. I placed the engine on the track, then the tender with the draw bar attached. I apparently twisted the draw bar in the process, causing the engine to flip off the table faster than I could react to catch it.

After I stopped swearing, I got the courage to pick the engine up. I looked and looked, but couldn't find any damage. I put it on the track and tried to run it, but it wouldn't move. A hum from the motor suggested it was jammed.

Further inspection revealed the sheet metal plate holding the trailing truck was warped and jamming the motor armature. I straightened out the plate, reassembled it and the Mohawk ran fine.

I got lucky due to: (1) solid construction by Lionel, (2) the engine apparently landed trailing truck first and the sheet metal plate absorbed the impact (but no damage to the truck) and (3) the engine hit my leg on the way down. I had a nice bruise on my leg as evidence. It's a heavy engine!

John