My coupler on the freight sounds boxcar periodically opens. Is there

an easy fix?

an easy fix?

Replies sorted oldest to newest

The easy fix is to glue it shut.

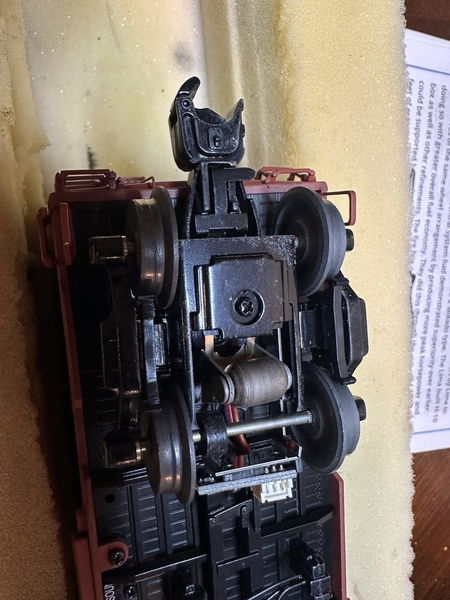

The truck wires in those cars are very short, and there's no good way to disconnect them other than the board socket, which has the wiring for both trucks connected to it. So unless you want to cut it and resolder it later, getting the truck far enough away from the car to really mess with it is not plausible. With freight cars, the easiest thing to do is just put a dot of super glue on the part of the knuckle that folds back into the coupler when you shut it, and just close the knuckle for good.

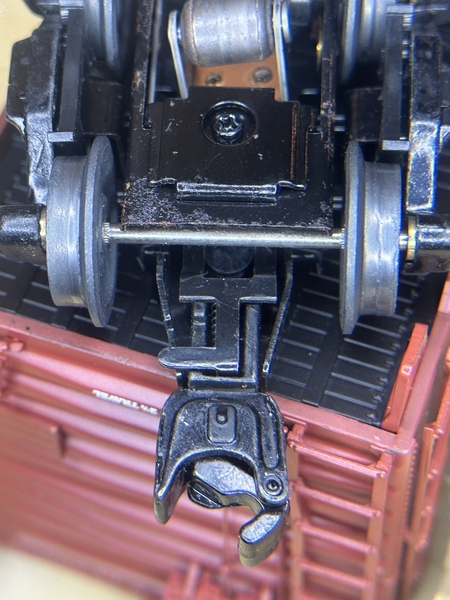

The actuating mechanism of those is buried in the folded tin of the coupler, in order to fix it you have to do some surgery.

Thank you for your thoughts. If it’s as complicated as Boilermaker1 states……. Super glue here I come.

anything can be fixed with super glue or duct tape!!!!!!

The very latest evolution of the 3R O Gauge truck and paddle coupler (MTH and Lionel) is IMO a very impressive piece of mechanical design. When they work right they connect with very little effort ("clink") and disconnect gracefully with a tap on the decoupling button instead of the loud "brap" and jump that occurs with the thumbtacks. My experience has been that about 1 in 10 or so don't work right (won't connect or disconnect). With used pieces (eBay) I'm guessing that may be due to abuse (slamming cars together by hand). I once tried to do the repair you refer to above and the lesson learned was "don't do that again". I had no idea how to repair what was wrong and it was impossible for me to reassemble by hand.

It would be great to see an exploded view of each (MTH and Lionel) with instructions on how to repair defective pieces if that information is available. How do they put the darn things together in the factory!?

You can only couple MTH Premier truck equipped freight cars to the Lionel Freight Car Sounds boxcars.

Andrew

In my club, most of us use very small black zip ties to keep the couplers shut, that way we are not permanently altering the car.

Andy

As John said, some surgery is required. It borders on major surgery and not for the squeamish. I had 3 of these lined up on the bench (before the Big Boy ![]() ) each with one coupler that didn’t stay closed. Two were Lionel sound cars, the other was an MTH Premier box car. The folded construction leads you to think that Lionel never considered the possibility of repair and that these would be throwaways.

) each with one coupler that didn’t stay closed. Two were Lionel sound cars, the other was an MTH Premier box car. The folded construction leads you to think that Lionel never considered the possibility of repair and that these would be throwaways.

You can get the two halves of the box apart by drilling out the 4 brass rivets but you cannot remove the uncoupling plate. This piece was folded in before the other folds and virtually impossible to remove without destroying it. You don’t need this piece unless you use the magnetic uncoupling track, if you do, stop and just glue the coupler closed.

With the coupler separated, I found 3 issues that keep it from closing properly: 1, the casting was not cleaned properly; 2, the stamped slider is not straight; 3, the spring is weak.

The tab on the slider (that you push to open the coupler) rests against the back of the coupler casting. I found extra metal on the casting keeps the slider from seating properly. File the casting so that it is straight up and down. The slider, itself, is a piece of stamped metal and frequently bowed. Flatten it out and check that the two ends are parallel to the bottom. Finally if the spring is weak, gently pull it apart. When the coupler is closed it should fit snugly.

After the Lionel pieces, the MTH car was a ray of sunshine. While the construction is almost identical to the Lionel, it is held together with screws making service a lot simpler.

These trucks are used on many high end cars but, in my opinion, the original postwar coupler is a much better design that still works well 70 or 80 years later.

With all of this, it is easy to see why people use glue, rubber bands, twist ties, etc. to keep their train together.

The tab on the slider is the most common issue. If it's bent incorrectly, it'll trip the couplers randomly. Truthfully, this is just a cheap and crappy coupler design.