C W Burfle posted:What I'd like to see made is an anvil long enough to go along side the field laminations and hold the rivet head for diesel motor trucks with plastic side frames.

Where, here?

|

|

that is the spot. And I guess a nice, long clincher for the other side.

I would imagine Carl at Hobby Horse could easily make such a clincher with little effort - just need to know the rivet size and the length and diameter needed to clear the side frames - and the business end of the arbor press.

I suspect a screw in place of the rivet might not work since there is so little room topside - the screw head would likely hit the frame and cause some uneven actions in a turn. Also, I'm just not a fan of putting screws where rivets once were.

C W Burfle posted:that is the spot. And I guess a nice, long clincher for the other side.

Jeff Kane sells a set of long riveting tools. I think they are long enough to do that job. He has a very good machinist that makes the custom tools, but some times he gets backed up.

David Johnston posted:C W Burfle posted:that is the spot. And I guess a nice, long clincher for the other side.

Jeff Kane sells a set of long riveting tools. I think they are long enough to do that job. He has a very good machinist that makes the custom tools, but some times he gets backed up.

Thank you. Jeff sells both Hobby Horse and his own tools. I am fairly certain the long tools he sells are Hobby Horse. I have both the Hobby Horse long Clincher set and the long anvil set. They are not long enough.

I think I used a Handrail rivet clincher last time, just held in my hand and struck with a brass hammer. The anvil was a punch chucked upside down in my wood vise. (As i write this, i realize it may have been a tool from the long clincher set)

Very Rube Goldberg.

Never strike a press tool with a steel hammer. You may create a small distortion that causes it to jam in your press. Some folks say the tool can fracture and cause injury too.

Back to the brushplate bearing topic:

Something I do that nobody has mentioned yet - I take brass tubing with 0.125 ID. I crimp the end to make a small flange on the press. Insert it snug tight with cyanoacrylate, with the flange on the inside face. I make the brass tube length slightly longer than the armature shaft. Then, I wedge a felt wick down into the tube up against the tip of the armature shaft and soak it with oil. I have a few engines, even a 313 bascule bridge that run as smooth as can motors now, and rarely need any attention.

GregR posted:Back to the brushplate bearing topic:

Something I do that nobody has mentioned yet - I take brass tubing with 0.125 ID. I crimp the end to make a small flange on the press. Insert it snug tight with cyanoacrylate, with the flange on the inside face. I make the brass tube length slightly longer than the armature shaft. Then, I wedge a felt wick down into the tube up against the tip of the armature shaft and soak it with oil. I have a few engines, even a 313 bascule bridge that run as smooth as can motors now, and rarely need any attention.

Greg, did you happen to take any pictures along the way? Sounds ingenious, like to see it, especially the end with the small flange. Source for the tubing? Local HS, Lowe's, Amazon???

Conventional Classics GP-9 with brass tube bearing (not visible in photo) and oil wick. Brass tubing comes from local hobby shop.313 Bascule bridge with brass tube and oil wick.RC car roller bearing installed in 200 series postwar alco. Very smooth operationThis bearing came from a Rhoomba robotic vacuum. When I periodically replace the spinning brushes, I save the bearings. Many end up in trains to serve a second life after being drilled to the correct diameter.GeoPeg posted:GregR posted:Back to the brushplate bearing topic:

Something I do that nobody has mentioned yet - I take brass tubing with 0.125 ID. I crimp the end to make a small flange on the press. Insert it snug tight with cyanoacrylate, with the flange on the inside face. I make the brass tube length slightly longer than the armature shaft. Then, I wedge a felt wick down into the tube up against the tip of the armature shaft and soak it with oil. I have a few engines, even a 313 bascule bridge that run as smooth as can motors now, and rarely need any attention.

Greg, did you happen to take any pictures along the way? Sounds ingenious, like to see it, especially the end with the small flange. Source for the tubing? Local HS, Lowe's, Amazon???

See above

GregR posted:313 Bascule bridge with brass tube and oil wick.RC car roller bearing installed in 200 series postwar alco. Very smooth operationThis bearing came from a Rhoomba robotic vacuum. When I periodically replace the spinning brushes, I save the bearings. Many end up in trains to serve a second life after being drilled to the correct diameter.

Greg, not sure why I never responded to your last post - very ingenious! And innovative!

I just finished my first Oilite bushing installation.

Back side

Front (Top) side

Since I don't own a drill press, I had to carefully enlarge the armature hole to 3/16" using a handheld drill - very unnerving, but it seemed to work OK. I lightly coated the interior of the new hole with epoxy then pushed the bushing in flush with the backside in order to shove any excess epoxy out the front. I then added just a little more epoxy around the front of the bushing - there is just a slight lip that extends above the brush plate surface. You can see how close the bushing is to the solder lugs. I believe the solder lugs could be trimmed a bit if absolutely needed, using a Dremel diamond blade. Immediately after installing the bushing, I assembled the brush plate without brushes, screwed everything down, and checked for armature tightness. I felt what I thought was a tiny bit of drag, so I grasped the end of the armature shaft with my needle nose pliers and applied side to side pressure in all directions to align everything - the armature now spins quite freely. So I let the glue set up then reinstalled the brushes & springs and it works like a charm. The results are really satisfying! Reduction of noise, higher rpm, and certainly less frequent need to oil. Using just the brush plate, I find myself oiling the armature hole every other time I try to run the engine

With regard to your method where you flare the (inside) end of your brass bushing, I'm thinking that might not work with an Oilite bushing, so I'm not going to press my luck on this one. ![]()

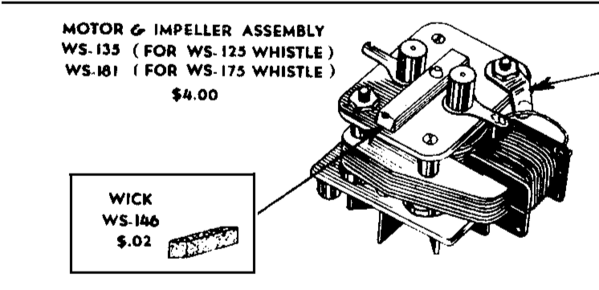

On this old style bearing plate from a prewar whistle (2689W), Lionel used an oil wick retainer, which reduces the frequency of need for lube. But most motors I repair don't have this wick retainer which is why I want to adopt your oil wick method.

I obtained the bushing from McMaster-Carr, and it measures as you have noted, they are 1/8"ID, and 3/16"OD, and only 1/8"L - I will get some longer ones next time to try your very ingenious oil wick. So where did you get the wick material? I see Jeff Kane has wicks, just wondering if Joanne's Fabrics or Michael's might have some locally?

I am also very interested in the RC car roller bearing installation you did, I wonder if you might provide some detail on how that was done? And did you think it was worth the effort?

George

On prewar equipment I am familiar with, the little sheet metal box along side the armature shaft was called the “grease box” and was filled with grease, not felt. I do not think Lionel made much use of oilite bearings prewar. I believe their bearings were high lead bronze like C972.

I have always wondered about the use of the felt wick with oilite bearings. In most oilite applications the bearing is supposed to provide the lubrication.

I regularly regrease the grease boxes. I think this is probably the first time this has been done since they are completely dry. Modern grease like red-n-tacky should last a long time in these application. I never use white lithium base grease as it turns to concrete in a year or two, providing no lasting lunrication.

Hi David - yeah, they are grease boxes, but with an Oilite bushing in there, I would think it needs oil, not grease. And I have found the same thing you did, these are usually filled with rock hard grease that dates back to the Egyptian era! ![]()

Your comments, "I do not think Lionel made much use of oilite bearings prewar. I believe their bearings were high lead bronze like C972. I have always wondered about the use of the felt wick with oilite bearings. In most oilite applications the bearing is supposed to provide the lubrication.

I don't know about the lead bronze, but it sounds plausible. I found info in the service manual (Olsen's site) under "Whistles" in the Cleaning and Lubrication section where it describes applying oil directly to the "...phosphor bronze bearing (I think this is bearing number WS-7) located in the whistle chamber cover", applied externally because it is porous. I wonder if that's the same as an Oilite bearing?

Here's a pic from that service manual, describing a very similar wick - not the same motor I modified, but similar certainly in principle.

Also, I'm not sure how well red n tacky works in this environment - you have a straight, smooth armature shaft spinning inside a glob of highly viscous grease. I think it will quickly be spun off the shaft, leaving a small, narrow hole in the grease. I don't see how it can migrate down inside the bushing? I like red n tacky for gears, because it does seem to stay directly on them for a while.

OK, stick a fork in me, I'm done!

Ya, you want to use oil on the top and bottom bushings.

I agree. Grease is more for gears; high pressure/temp. roller/ball bearings. Oiling will help flush debris better. Heavy machine oils are a possibility, should last in wells if clearence is tight, too.)

Zippo wick for oil wick. A sliver of fiberglass cigarette filter. Tea light oil/fuel ''candle" wicks.

I find red & tacky a bit thick and have been using Lubriplate Aero more in/on most the last few years. It's softer than heavy wheel bearing grease, with a 190-220° weep temp, safe lithium base, I haven't ever seen Areo get crusty.

I also have a few plastic safe teflon lubes that I like, a thin, very light clear grease in various sqeeze tubes and brands; I'd trust it to slowly migrate down in a tiny well. T-9, Boeing's teflon dry wax spray is great, plastic safe, so far paint safe (oh, the awesomeness. Let one drop permeate a bearing, etc., let it dry 5 -10 minutes . Looks like water stains on glass or spoon untouched; slick like graphite. Lasts .)

Plastic safe Reel-Butter oilings, Birchwood Casey Sheath metal wipe & slow but sure oil, agitate, oil, wipe for casual removing, treating, & preventing more.

'Bannana oil", good stuff else where, sometimes turns to a thick sludge on electric motors ...I'm thinking about that because it clogged a big motors wick and bearing.

A hole is all any bushing needs for a lube boost. It doesn't hurt to have more lube on an oil-lite than I know of. It's more like some things dont need more and it's not gonna wear fast... but why not slow it more? Significant drag is about all I can imagine..but more than R&T grease? ![]()

A tiny piece of metal/plastic/etc.. tube (hobby,pnumatic,weedwacker/etc,is all you need for a well. Maybe a dot of super glue outside of the tube.(I just saw loc-tite has a flexible/shock proof gel super glue!?!)

RC fuel plumping/fittings would make nice wells if you have/buy small tap. (& bottoming/seat angle on the bit & a bottoming tap to get "serious")

The right hole or fitting and you could force flushing bearings by spray lube nozzle-straw, or use blunt syringe geaser, squeeze oiler, etc.

I liked where these repais went. Printers and media players, tape/VCR/cd/dvd/camera drawers/lids provide another source of all kinds of tiny bushing and bearing "wonders". (Surprisingly strong motors the size of pencil erasers etc.)

My MPC General has low profile,flat, armature end play/thrust's, ball bearings that I bet you someone interested here might like to see (there are two bearings/cages & hard washers/machine shims for arm. thrust surface races)(Fishing reels are another source of tiny goodies like these too ![]() )

)

R.I.P CW. 😔

Access to this requires an OGR Forum Supporting Membership