I really dislike smoke units in their current form. They are messy, unreliable, run too hot and stink, especially as they decay and ultimately fail. The residue left behind trashes my weathering efforts and is difficult to impossible to clean. I was recently watching a review on a new Hornby steam engine and saw that they now have water based smoke and it looked pretty good. Being intrigued, a quick search brought up some experimental videos showing the use of ultrasonic humidifier boards in some large scale engines. This is basically the same tech Hornby uses from what I can tell. I ordered some usb powered humidifier boards on Amazon for less than 3 bucks each to play with. I never knew about these strange and interesting devices and thought for a few bucks why not?

Here’s some quick vids in the shop and in the layout showing one of my first thoughts for their use:

Right off the bat what I liked was the instant on effect. Also no need for a fan. As long as the wick shown is damp and in contact with the piezo (?) disc, the water is vaporized instantly. I really like the fact that there is no smell and it doesn’t hang in the air. Most importantly for my purposes no oil! The control board runs off 5 volts DC and can probably be controlled with a puff and chuff type circuit. At this point I’m not sure how the stream can be slowed down but as you can see it’s pretty much instant on/off. No warmup required!

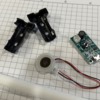

Here’s a photo of the components:

Why can’t we have this in O gauge?!