I was thinking oil or solvent based weathering paint would be required for compatibility with this water mist system. But no evidence of moisture after hours of operation... Hmm. Maybe sporting chaps might try water based acrylic weathering despite having this system onboard?

I’m thinking a regular sized smoke unit wouldn’t hold enough water volume to run longer than 10-15 minutes max. The wet wick by itself will run about 20-25 minutes or more before petering out. Not a lot of water being used at all.

It looks like this system has a lot of potential. However, there has to be a method to isolate the water chamber and filling it from the electronics in the engine. I do like the method on the Hornby locomotive of an easy to remove the water chamber from the locomotive.

Marty

Water would be better for my wifes asthma.

From the Hornby article on their OO size steam engine. Tank size, 5ml or 1/6th of an ounce. Run time 30-40 minutes. Watching the video it does tend to "rain down" within a few seconds.

Looking at the off the shelf 16mm diameter units some show 50ml/hour. 1.7 ounces an hour. The Hornby unit must be much smaller to do around 10ml an hour. Also the off the shelf units run 2W or about 400 milliamps at 5V. They appear to suck in the water from the back or from a wick in the back. 3000 hours avg life of the pizoelectric disc.

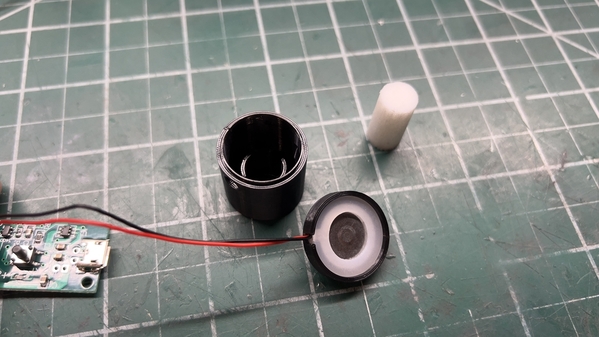

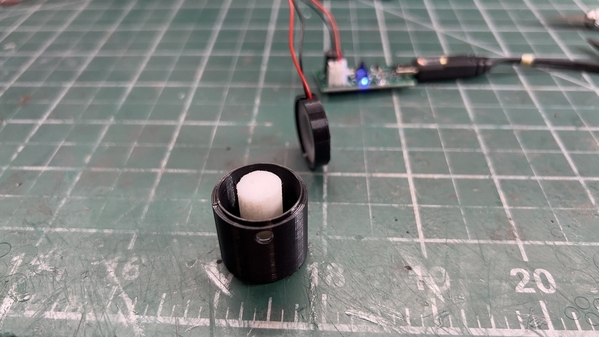

3 Key parts. 1. wick and Pizoelectric disc. 2. Driver board, most have 5v imput. 3. Power convertor to get to 5v.

Most off the shelf components for 3 rail or AC power conversion may not fit in the engine. DC-DC power conversion units are smaller. Electronics in the Tender with wires to the engine would work.

A 3d printed adapter could fit the disk in a Lionel Postwar smoke unit. The problem is there would not be much storage for water. Only 3milliliters. Need to replace the complete smoke unit to get 30ml of water storage for 30 minutes of run time. 3d printing a holder and tank should not be a problem. Probably have to fill via the front boiler cover. May have to apply a sealant to the inside to assure water tight depending on the printer and method.

Would love to have a controller board that would take 10-20 V AC/DC and be small enough to fit in the loco.

@UnclePeteRR posted:How big is well or tank that feeds the unit?

IF smoke unit requires 5v, would it have to be run thru a pot?

The "tank" is as big as you care to make it -- as long as the white wick is in contact with the water, it will draw it up into the transducer. My two installations use a dollar store snap-top container of about a quart or so, though I usually only fill it to about half (enough to cover the exposed wick).

I power my units through a micro USB cable (the 5 volts is DC only).

[Please note I am talking about stationary installations on the layout, not an engine-mounted smoke generator replacement! ![]() ]

]

@VHubbard posted:Would love to have a controller board that would take 10-20 V AC/DC and be small enough to fit in the loco.

It looks fairly easy to compress this board a bunch, it's apparently just a 108khz waveform generator. As you can see, tons of wasted space. You could clearly make the power input and emitter connection much smaller. The pushbutton is unneeded in the locomotive. Already the modified board is probably less than half the size, probably 1" square and maybe 5/8" tall.

I already have a compact switching power supply running from track power that would be suitable, 5/8" wide x 3/4" long x 1/2" tall.

Attachments

@gunrunnerjohn posted:The pushbutton is unneeded in the locomotive.

One caution: the button is used to start the unit, and then cycle to intermittent action before turning off the power. There may be an easy workaround, but unless you redesign the circuit board and/or rewire the driver unit, some button equivalent will still be needed to start the mist. Perhaps wire it into your command control system for remote activation?

Attachments

Many years ago, we tinkered around with this idea in the Lionel CA office. It worked real nice producing "smoke", but after testing awhile we noticed the layout track was rusting! I also recall one of our club members setting up a Halloween display with a smoking caldron and his track rusted too. Potential, with some limitations. FWIW...

@SantaFeFan posted:Many years ago, we tinkered around with this idea in the Lionel CA office. It worked real nice producing "smoke", but after testing awhile we noticed the layout track was rusting! I also recall one of our club members setting up a Halloween display with a smoking caldron and his track rusted too. Potential, with some limitations. FWIW...

Using Tubular or Fastrack I can see this happening quite easily. Stainless Gargaves, Atlas, or MTH, are much more corrosion-resistant. I have a layout stored in a show arena without any temperature or humidity control that is made up of stainless gargaves and realtrax, no problem after 20+ years. The same layout with tubular only lasted 2 years, hence the change to something better.

I think this whole thing with water atomization was discussed a few years ago: https://ogrforum.ogaugerr.com/topic/smoke-units-3

I have used some of these water-atomizing discs previously with decent results. The best one so far is the Menards Nuclear power plant, the cavity in the stack is plenty deep to fit an atomizer, creating a nice plume of vapor with most of the water resettling in the stack. @Adrian! did something much better using a mini fogger: https://ogrforum.ogaugerr.com/...1#181903135682511141

Keep in mind these are atomizers, you can atomize any number of liquids including the smoke fluid you use now if you don't want water all over your layout. Look into how fogging machines work, why couldn't one use the same fogging liquid for these little atomizers?

@Steve Tyler posted:One caution: the button is used to start the unit, and then cycle to intermittent action before turning off the power. There may be an easy workaround, but unless you redesign the circuit board and/or rewire the driver unit, some button equivalent will still be needed to start the mist. Perhaps wire it into your command control system for remote activation?

I suspect it's as Norm states. In any case, My point was that a board redesign would probably be needed to make it truly small enough to easily fit into O-scale locomotives. You could also just use an opto-isolator like I do for many functions and when smoke was called for by the TMCC board, that would trigger the PB function.

The board appears to simply be a 180khz oscillator with enough drive to power the mist generator.

I know that Chris @lehighline has an atomic power plant that vaporizes water, he didn't seem to have any rust issues, but maybe he'll chime in.

Actually, if you let it sit long enough next to trackage, the trackage will rust. My solution was to periodically dry the rails and ties. Not perfect, but at least no rust! Running this system in an engine may not pose a rust issue, as the engine is more or less constantly moving. I can see where having a big enough reservoir to keep the disc supplied could be an issue. Another possibility for a stationary system like my power plant would be to have a fan to direct the vapor away from the track or other water sensitive locals.

Chris

LVHR

@H1000 posted:Using Tubular or Fastrack I can see this happening quite easily. Stainless Gargaves, Atlas, or MTH, are much more corrosion-resistant. I have a layout stored in a show arena without any temperature or humidity control that is made up of stainless gargaves and realtrax, no problem after 20+ years. The same layout with tubular only lasted 2 years, hence the change to something better.

Maybe some type of product could be used to resist the rust on top of the Tubular or Fastracks H. If there is only light surface rust on the side of the rails a coating of clear Matte Krylon Fusion might get a good look instead of trying to mix up a rusty dirty paint color to apply to the side of the rails.

I use Realtrax but my main concern would be rust occurring in and around locomotives , rolling stock , copper wires , metal operating features , etc. ![]()

Y’all with tube track, or fast track are looking at this all wrong!…..install the water vapor smoke unit, and get free track weathering, without doing any extra work 😁

Pat

I think some of you guys are talking about those ultrasonic foggers. They put out quite a bit more mist compared to the devices I am playing with.

Wow, once this is perfected we will have to work on making our water towers actually hold water for refilling. That would be so cool. Maybe even a little tank in the tender, with a pump and water line, to the tank in the engine which would have a float switch that would turn the pump on and off.

@H1000 posted:I think this whole thing with water atomization was discussed a few years ago: https://ogrforum.ogaugerr.com/topic/smoke-units-3

I have used some of these water-atomizing discs previously with decent results. The best one so far is the Menards Nuclear power plant, the cavity in the stack is plenty deep to fit an atomizer, creating a nice plume of vapor with most of the water resettling in the stack. @Adrian! did something much better using a mini fogger: https://ogrforum.ogaugerr.com/...1#181903135682511141

Keep in mind these are atomizers, you can atomize any number of liquids including the smoke fluid you use now if you don't want water all over your layout. Look into how fogging machines work, why couldn't one use the same fogging liquid for these little atomizers?

some feedback after 3 months of service on that accessory....

GOOD STUFF:

The major thing that drove us to the microfogger was we needed a fast kick. The accessory might be sitting for 3-4 hours before someone pushes the button... and the whole sequence is only 10 seconds or so ... so we need to generate a large volume of smoke like 2ft cubed very very quickly without any kind of warmup period. That's what this fogger does well. Also, It's brain dead to interface with... a 3.3V discrete trigger (1 = smoke 0 = no smoke). It doesn't seem to leave any film or residue since we put it into the layout and it doesn't really go through the fog fluid that fast. We're still on our first 300mL bottle like 3 months later.

BAD STUFF:

1. That said, it doesn't like to lie down, if you lay it on it's side it starts spitting hot fluid out.

2. The emitter gets dirty pretty easily and constantly needs Q-tip cleaning.

3. Also for whatever reason the internal circuit design is stupid. It uses a USB port to charge an internal battery. When the power switch is on it will accept the trigger and fog, but won't charge. When the power switch is off it doesn't smoke of course. So you're stuck running it off battery power. We have to keep lifting it in and out of the cooling tower on the building and the wear and tear is already starting to show 3 months in.

I'm actually planning another accessory design right now that needs smoke but I'm really on the fence about using another of the same device. 3/4 of the time it gets left on after the club closes and the next opening, the battery is dead. Overall what's happening at AGHR is as we add more and more of these very active accessories full of sounds and lights and moving parts and smoke... the week-to-week maintenance needed (smoke fluid, cleaning the smoke emitters, lubricating moving parts, topping up the flash paper, redoing the alignment on the UFO that abducts the cows and so on)... it just becomes a full time job beyond keeping the trains themselves running (which is already a full time job).

An observation and some questions...

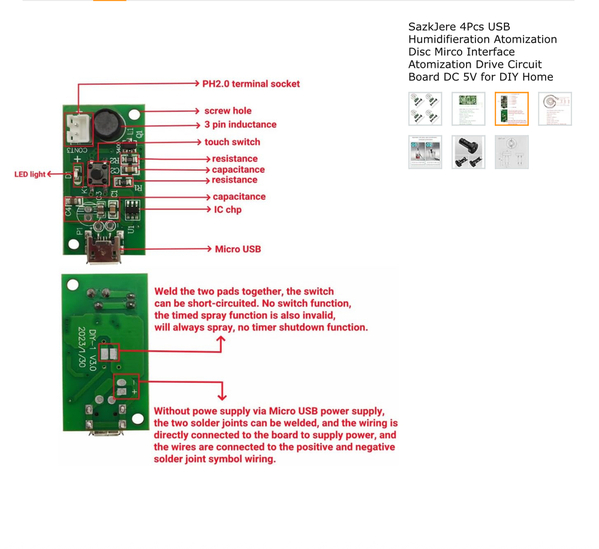

Zooming in on the pics, it looks like some of these devices have clearly-labeled input voltage locations where the power source wires can be soldered (to eliminate the need for a USB plug) and some don't. Doing some extra work to bypass the USB is probably not a big deal for those folks who are skilled at soldering circuit boards, but I'm not one of them. This also assumes that the actual product will match the picture, which might be a bad assumption.

Can the wicking device be cut shorter? (I'm assuming that it must be, as it looks like it would never fit inside most locomotives, but asking to be sure.)

I found the devices on big A and eB, but they range in price from $5.50 to $7 and up - didn't see any in the $3 range like was mentioned in an early post. Source / link?

For conventional locomotives, is there a commonly-available device for converting track voltage to the 5v DC that is needed by the humidifier unit? Source / link?

@Mallard4468 posted:An observation and some questions...

Zooming in on the pics, it looks like some of these devices have clearly-labeled input voltage locations where the power source wires can be soldered (to eliminate the need for a USB plug) and some don't. Doing some extra work to bypass the USB is probably not a big deal for those folks who are skilled at soldering circuit boards, but I'm not one of them. This also assumes that the actual product will match the picture, which might be a bad assumption.

Can the wicking device be cut shorter? (I'm assuming that it must be, as it looks like it would never fit inside most locomotives, but asking to be sure.)

I found the devices on big A and eB, but they range in price from $5.50 to $7 and up - didn't see any in the $3 range like was mentioned in an early post. Source / link?

For conventional locomotives, is there a commonly-available device for converting track voltage to the 5v DC that is needed by the humidifier unit? Source / link?

As long as you don't mind waiting a few weeks, how about $1.25/ea for four of them on Amazon? Free shipping as well.

Search for B0CYGTBGNP on Amazon.

Attachments

@Dave Zucal posted:Wow, once this is perfected we will have to work on making our water towers actually hold water for refilling. That would be so cool. Maybe even a little tank in the tender, with a pump and water line, to the tank in the engine which would have a float switch that would turn the pump on and off.

Wait - Lionel already did that, at least the water in the tank thing, in the 40's - 50's.....

@harmonyards posted:Y’all with tube track, or fast track are looking at this all wrong!…..install the water vapor smoke unit, and get free track weathering, without doing any extra work 😁

Pat

Yes - and don't forget us GG steel track guys.

Water and electric trains? Electronic electric trains? Mmmm. Down deep, it's a bothersome idea. But that's OK - I don't use smoke units much anyway. They are a maintenance item I don't need. Generally. Also, I like the way that smoke fluid smells - so long as it's un-perfumed, or at least perfumed with something worthy - like coal or diesel fuel smell. Smoke fluid "smoke" is not smoke, anyway - just a vapor, too - but it's not a corrosive one.

Anyway, my model RR'ing career is past major changes.

@Norm Charbonneau posted:

Thanks, Norm, that'll be helpful in rewiring my modules (my "slow boat" versions didn't come with any documentation, Chinglish or otherwise!).

It appears from your graphic that I can just solder the two pads on the back together to defeat/bypass the button switch (I don't really need the intermittent action option, which will be disabled), and I can replace the plug-in micro USB power connection with a buck converter set to the proper voltage and wired to the other two pads.

I forgot until I saw this thread that my daughter-in-law got this for me.

Will this cause a corrosion issue with long term use?

I must say I do like the smell of some smoke fluids and would miss that.

Looks great but I’ll never be convinced that water and electric trains work together.

@NJCJOE posted:I forgot until I saw this thread that my daughter-in-law got this for me.

It's not moving! ![]()

![]()

@gunrunnerjohn posted:As long as you don't mind waiting a few weeks, how about $1.25/ea for four of them on Amazon? Free shipping as well.

Search for B0CYGTBGNP on Amazon.

Thanks - at that price it's worth a try. Absolutely nuts that one needs to search for B0CYGTBGNP to find a USB humidifier, but what the heck. The slow shipping works for me - it's going to be weeks before I actually do anything with it anyway.

I 3D printed a very basic smoke unit for the ultrasonic thingy. It can hold up to 3ml of water in the reservoir and will run about 7-8 minutes until the water is used up and the wick is dry. I think this is pretty reasonable performance and by adjusting the reservoir capacity it could be made to run longer. The unit could be made in any shape or capacity to fit any type of locomotive (or rolling stock, accessory, etc.).

Here it is running out of water and as long as the wick isn’t totally dry, you can see that it gets back to work very quickly.

Attachments

@Mallard4468 posted:Absolutely nuts that one needs to search for B0CYGTBGNP to find a USB humidifier, but what the heck.

B0CYGTBGNP is the Amazon product number for the ad page, since we can't post real links, that's the next best thing.

For what it's worth, I'm not convinced it'll rust rails. Especially for those of us using the No-OX grease or Ross/Gargraves/Atlas track. I was just stating what I have always heard about putting real water on a layout.

I also think smoke fluid is messy and prone to it's own problems.

My steel mill layout will be heavy on the smoke effects. The opportunity to possibly use water in some spots is definitely enticing! I also like watching people tinker with stuff.

Would someone please remind me what the downside of using the old-style Lionel smoke pellets is. As a kid of the 50's, I'll always love the smell of those smoke pellets. As I recall, they did leave a little residue of white dust, which was easily removed.

Hal

John I'd be in for a redesigned board w/ a fixed voltage P.S. vice having 2 seperate boards.

@HMS4935 posted:Would someone please remind me what the downside of using the old-style Lionel smoke pellets is. As a kid of the 50's, I'll always love the smell of those smoke pellets. As I recall, they did leave a little residue of white dust, which was easily removed.

Hal

Pretty simple, fan driven smoke with chuffing, not to mention lots of smoke. ![]()

My water smoke units finally arrived. Prodigious smoke output, but the condensation is a concern - see the photo. Not sure that I'm going to trust it around any electronics. Also, the really cheap ones are no longer available on Amazon - looks like similar items are now $7-8 each. Not expensive, but not such a bargain.

Attachments

@Mallard4468 posted:My water smoke units finally arrived. Prodigious smoke output, but the condensation is a concern - see the photo. Not sure that I'm going to trust it around any electronics. Also, the really cheap ones are no longer available on Amazon - looks like similar items are now $7-8 each. Not expensive, but not such a bargain.

Pretty sure I bought them all (I ordered like 20 sets) ... LOL

I'm building a new accessory that needs A LOT of them. They work well for what they are. Provided the rod is soaked up to the piezo they have fast kick, which is good for modeling explosions or cannons and stuff that needs a quick on time and a fast pulse

I got a few of these, four for $5, couldn't pass it up. They work great, I'm thinking they'd be perfect for buildings. I notice you can extend the stack on top if you give them a small vent right at the emitter, apparently to create a draft. If it's sealed, it doesn't work well at all, but 1/8" gap and a 6" stack is no problem. Like Norm, I'm thinking of a 3D printed reservoir and stack, and all-in-one deal. It would be easy to add a fill tube for the tank as well.

Would this cause metal tracks to rust?

@Mark V. Spadaro posted:Would this cause metal tracks to rust?

Probably depends on usage and the humidity in your layout room. Can the water vapor evaporate before falling to the ground? In my basement, I'll need to be very selective about usage and location.

In the online listings, these devices are described as a humidifier.