I am looking for ideas for a sanding tower and facility. I have an MTH tower, but wish I purchased the Weaver tower some time ago. There aren't many options available and am wondering how others have addressed this shortage on their layouts.

Replies sorted oldest to newest

That second photo looks familiar!

Harry hieke has a nice version as well. Depends what style you are looking for. That second tower posted by Joe was mine, it's very nice

Boo Man posted:I am looking for ideas for a sanding tower and facility. I have an MTH tower, but wish I purchased the Weaver tower some time ago. There aren't many options available and am wondering how others have addressed this shortage on their layouts.

Yes! Thank you I am in need of the same ideas.

Not stated whether a modern diesel or period steam facility is desired....I can't quickly find the box but my steam version is, l think, Korber. I think there is a kit for the Chama sandhouse that might need to be bashed. Must be some more steam kits out there.

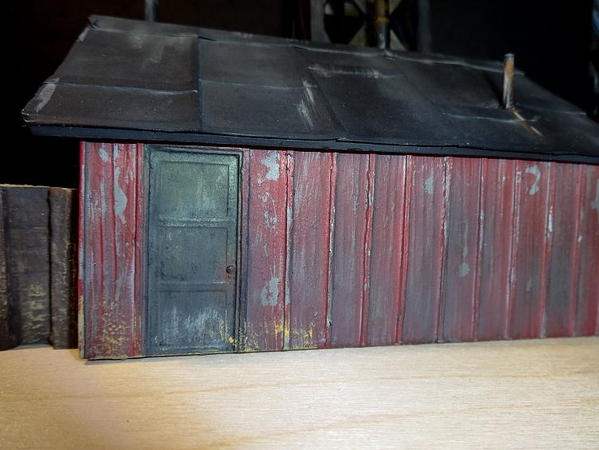

I model ON30 so a little different. It's loosely based on the one in Chama. Russ

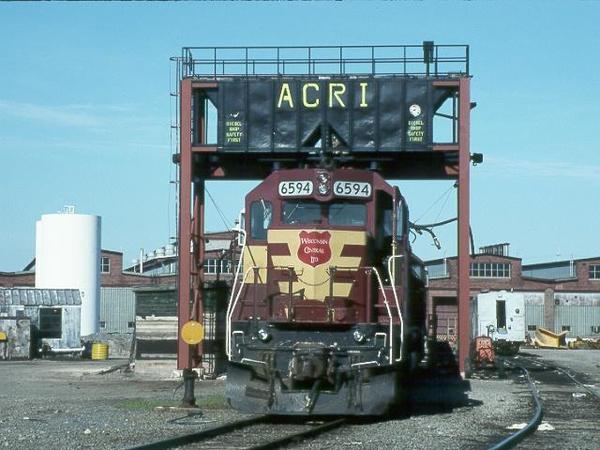

So here's a good example of how I seek an answer to a basic question like the OP's...

If I want to see 'examples' of "X", I go to Google images.

In this case I googled "Railroad Sanding Tower Images", and....

BINGO!

![]()

Talk about inspiration for D.I.Y.!!!!!!

Just a thought......FWIW......always.

KD

This is my take, I scratch built a primitive sand building then bashed a Lionel sand tower and attached it because on my railroad nothing goes to waste.

Paul

I am modeling the transition era, 1955-1961. I just bought the Golden Gate coaling tower and wanted to add a sanding facility near it. There is enough info on line to explain how a coal towers operate, but looking at sanding facilities I am not clear on how sand is moved from the dry house to the tower. I've read that it is pumped, but not clear how that works with an aggregate versus a fluid. Any good sources anyone have on how they operate. I'd like to read about it before coming up with something for the layout.

Joe,

I believe that first one is Korber. The other three are cool designs. The one with the hopper is really cool.

CQRuss,

Yours is along the same lines as the Korber.

KD

Did that, but wanted to see more ideas. Google and youtube are great and easy resources, however, this forum is loaded with some very creative people. Just looking for as much as possible. Thanks for the input.

Paul,

I'm embarassed, I did not pay attention and notice it back there when ogling your tanker/tank. I like the idea of what you did for the sand house and it follows the theme of the Korber.

They look pretty similar. Maybe a dry house will be my first scratch build attempt. I hope more will post their facilities to keep getting more ideas. Thanks for all of them so far.

Bob

Bob in keeping with my ON30 sand house this is quoted from a DRGW source on how my style worked. Russ

"First is the open sand storage bin pictured on the left. From there, the sand is shoveled by hand through a window-like opening into the main shed. In this structure, known as the drying shed, the sand is dried and screened by a special coal fired stove. When a train takes sand, compressed air from the engine is used to blow the sand up into the tank on the wooden tower outside of the sand house. Gravity then feeds the dry sand into the sand dome of the engine."

I scratch built this sanding tower to somewhat resemble the facilities being used by the N&W, though probably more like 60's era than steam. I believe most of their sanding apparatus was integrated with their coaling structures, at least in the larger yards.

Attachments

Weaver

Rich, nice job on those. They look great. Mike, the Weaver tower is my envy. Looks good.

CQRuss, that is great information and is exactly what I need to understand it before modeling it.

dkdkrd posted:So here's a good example of how I seek an answer to a basic question like the OP's...

If I want to see 'examples' of "X", I go to Google images.

In this case I googled "Railroad Sanding Tower Images", and....

BINGO!

Talk about inspiration for D.I.Y.!!!!!!

Just a thought......FWIW......always.

KD

It's my go to search whenever I need some imagery...surprised more don't avail themselves of this .

Bob

Not exactly the way we wanted to do it, but the tracks are on a curve so that changed the spacing for everything so the Big Boys would clear when entering the facility. Korber sand house (I added the door out to the storage bin),and sand tower along with the Weaver tower. Our market is really lacking in this department, especially for modern style sand towers.

Sand cars are spotted and then the portable conveyor is wheeled over to transfer the sand to the bin. The pump is inside the house which pumps the sand after it's dried, to the two sand towers. I would rather of had a pit to dump the sand into between the rails, or an elevated track for the sand cars like Santa Fe used at San Bernardino, but we just didn't have the room.

Attachments

Here's one from Patrick H a few years back. I saved his photos because I really like the way he put everything together in his facility. The big difference is he had long straight tracks to utilize where both of ours are on a curve.

Attachments

Late addition for current seekers of sanding options. Found this buried on a shelf with train boxes, while looking for another kit I have somewhere for a sanding facility......... Quick way to get the tower itself, anyway. It's die cast metal. Easy to take a cutting disk and remove the second track's pipe, support structure parts and hose to make it a single track unit. Hoses could be shortened for clearance if you like, or tied back in some way as they probably would be in prototype use so they can be put in position to fill a steam sand dome or diesel sand filler port. Spray it flat black and it will look a lot more "steam era."

MTH Railking 30-11040 "O scale sanding tower"

jcovert posted:Harry hieke has a nice version as well. Depends what style you are looking for. That second tower posted by Joe was mine, it's very nice

Did not see this - thanks Jeff

Joe

Boo Man posted:I am looking for ideas for a sanding tower and facility. I have an MTH tower, but wish I purchased the Weaver tower some time ago. There aren't many options available and am wondering how others have addressed this shortage on their layouts.

Maybe we should push GGD to rerun that Weaver models sand tower?

This is one of the first projects I ever did. It's based on a picture of Milwaukee Road sanding tower I found on line. At some point, I will redo it, but until I do, I will keep it in the background.

Attachments

Mine is a an older Model Tech Studios craftsman kit that I built probably in the mid-2000s. It was a nice kit and looks decent next to the Gloor Craft coaling station and I think a Gloor Craft water tank. The tank is one of the three things on the layout that I did not build. I bought them from Frank Miller when he was disassembling his monster O'scale pike.

I have knocked the spout off at least three times. This time I used epoxy to put it back on. The spout was a resin part and it's fragile.

Attachments

Attachments

Attachments

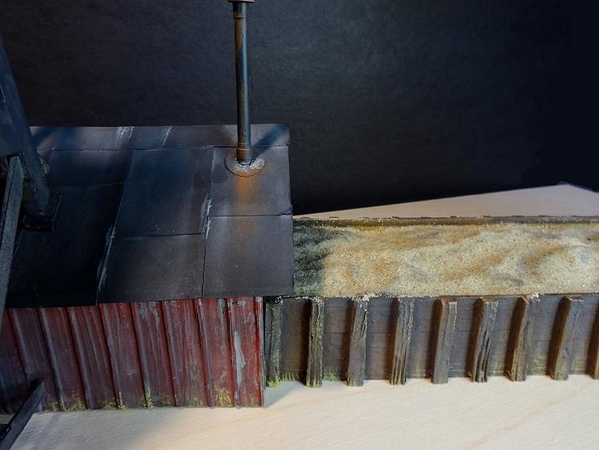

Joe, here’s the story on my Grand Trunk coaling tower:

https://ogrforum.ogaugerr.com/...aven-coaling-tower-1

Like a lot of coaling towers, it provided sand too. The hardware can be seen on the left side. The man door at the base leads into the drying room.

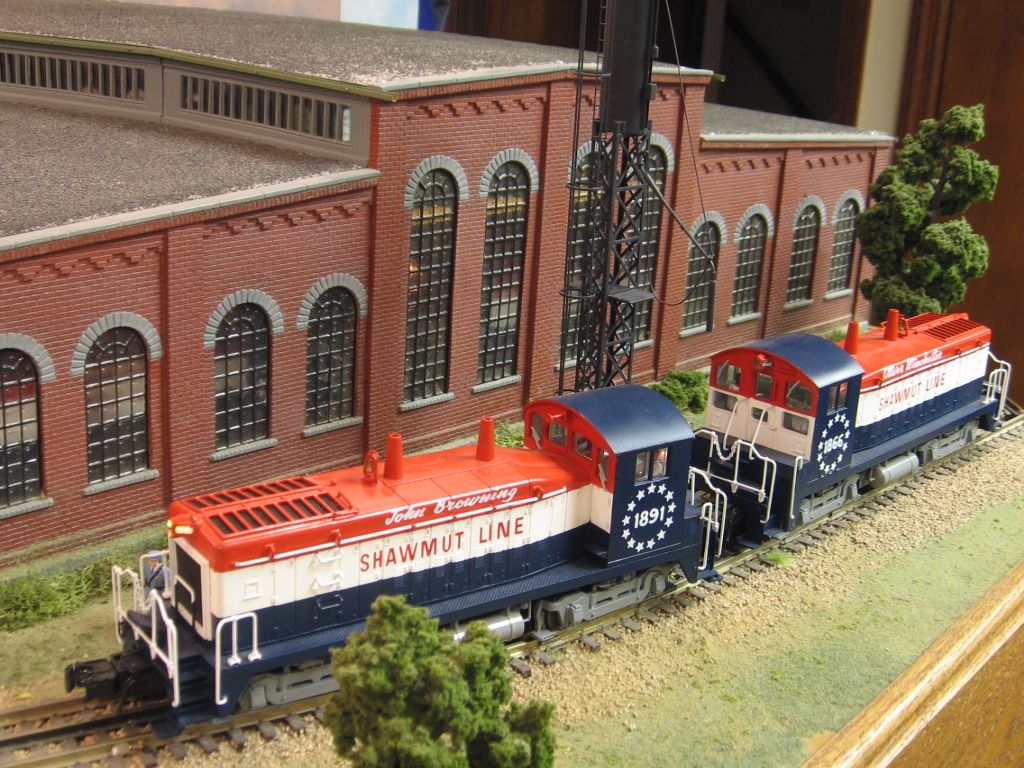

Here's a couple of shots of what I did. These are Weaver sandtowers. Korber sandhouse.

Attachments

Norm Charbonneau posted:Joe, here’s the story on my Grand Trunk coaling tower:

https://ogrforum.ogaugerr.com/...aven-coaling-tower-1

Like a lot of coaling towers, it provided sand too. The hardware can be seen on the left side. The man door at the base leads into the drying room.

Norm - I assume you scribed the sides of the hardboard to get the 'cement' lines?

Joe