Are you sure you want to put ring terminals under the truck mount screws? That will be a most unreliable connection! The better place is to bring a wire up from the truck and connect to the frame of the truck. If the truck has plastic bearing inserts, you'll have to have axle wipers and connect to the wipers.

Thanks John,

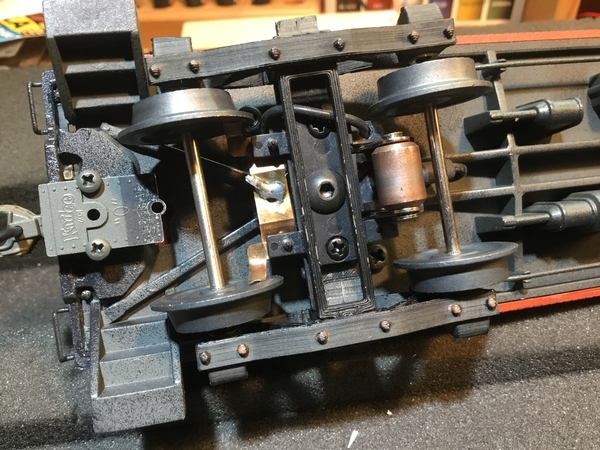

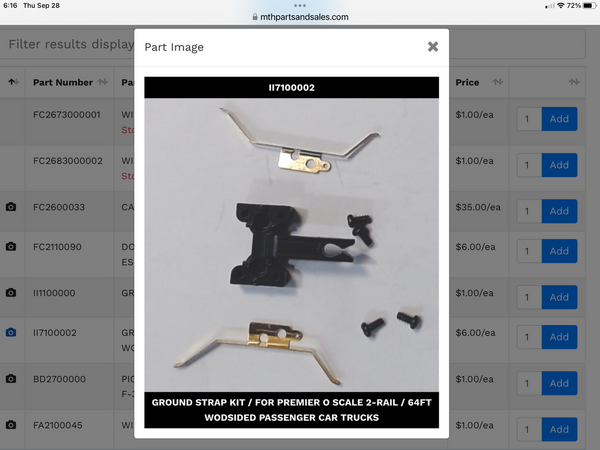

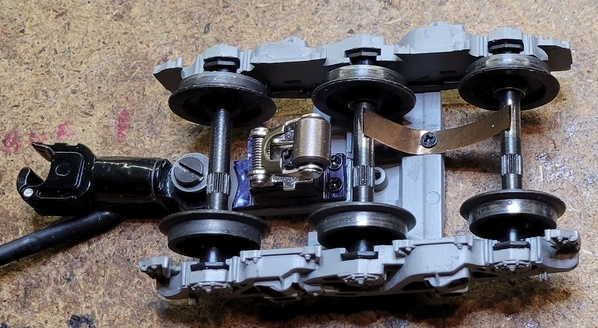

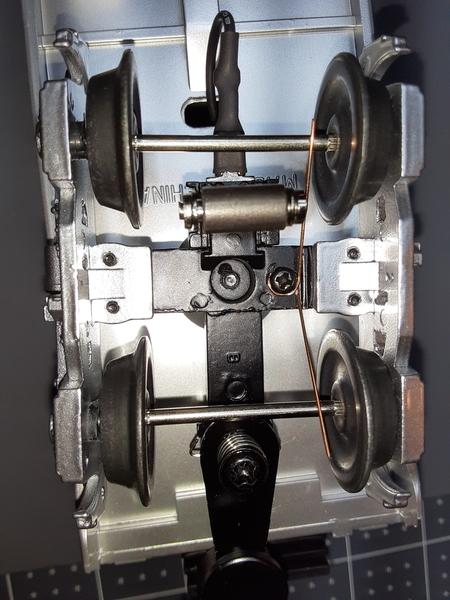

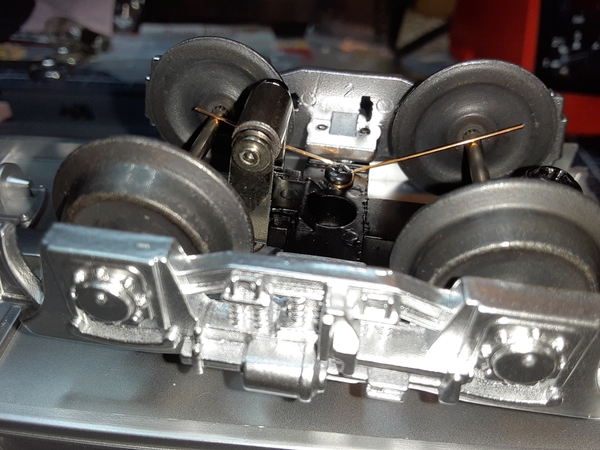

It's a Lionel Santa Fe baggage car that had no lights. My grandson wants it to light like the rest of the set that he has so I am just going using the same setup as on the other cars. The roller was available from Lionel, but the 2-axle wiper strips were not. They are attached to the trucks via a small metric screw and the pre-threaded hole is there on the truck. I bought the metric screws that fit. I made axles out of .020 phosphor bronze wire, twisted the center into a loop for the screw. Then just screwed them down. They are under tension.

So it looks just like the others underneath except that there is a wire wiper instead of a strip.

All the other cars use small ring terminals on the truck mount screw. It rotates with the trucks and seems to work well on the other five cars. Short of that I would have to drill and tap another hole for the feed wire on the truck because the wiper mounting screw isn't large enough or deep enough to hold both.

Unless you have a better way under the circumstances? I would appreciate that as always.

Thanks,

John