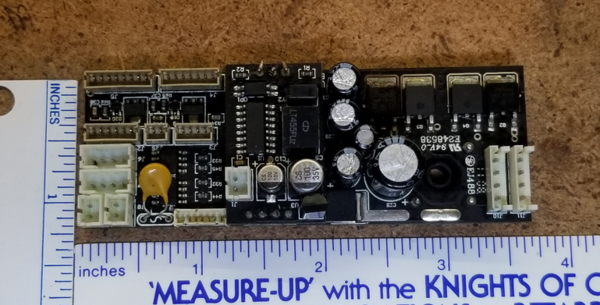

Nice professional job. I hesitate to ask, but how many hours is the complete upgrade going take take? To say this is a time consuming and detailed operation wouldn't be overstating the case I suspect!

Welllll, the more I do. The faster it get. With the electronics its almost the same install every time. To be honest. I usually spend a lot of time through out my day(s) at my actual job (day dreaming), thinking about how to approach a project and doing parts research before I even place a part order. I take pictures of what I have to work with as well. I usually have about 4-5 hours (with distractions) at most after work to be able to work on projects. Some days no time such as Life. So it seems like a long time. 😁

(I had the tender done the same day I posted that teaser video.)

SO! The Class A I did at first took me 24-26 hours. Finding the best ways to do the job. Taking my time. I know I could do it faster but I want a good base method at first. When I did Brians Class A. It took me just about 12 hours from start to finish. And thats me with tools in my hands. I’m sure if I get a 3rd to work it will be less.

This project kinda caught me off guard. Wasnt even thinking of doing one of these. I mentioned to Brian that it might be to difficult to even add whistle steam. But I got it. I looked at a ESE we had at Eastside before I got his engine. Just to get good base idea of how Lionel did it. I knew it be very similar to idea with the Dreyfus.

If I did another one of these, I know what id need to do first and last, this would cut down the turn around time to 12 hours if not less.