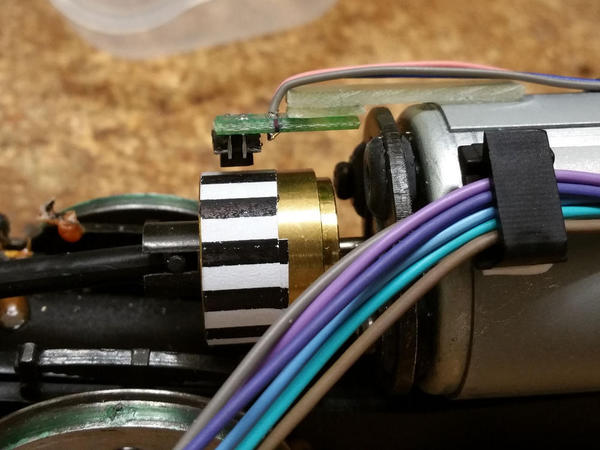

I have a steamer with a 20.8mm flywheel, and I'm wondering if anyone has installed the PS/2 kit on a flywheel of that size, and if there were any issues. One fly in the ointment is the gear ratio is a pretty fine 43:1, so the motor would be cooking along for any real speed. I'm concerned with the encoder's performance at high speed. I have the strip files that the Hikel boys published, and it looks like the .053 spaced strip is the size to give me 24 bars. However, I was thinking, as this locomotive has such a large gear ratio,would it be better to use bigger stripes and less of them to accomplish the desired goal? Most locomotives are down in the high teens or low twenties for a gear ratio. Is this as simple as just using perhaps fourteen or fifteen stripes?

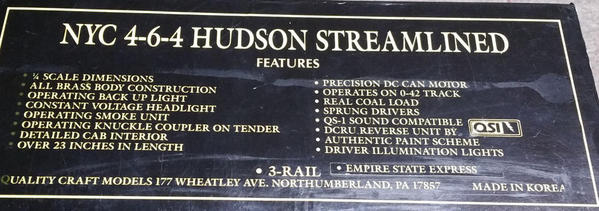

This is a brass Weaver 2-rail Hudson, FWIW.