By the way Ameen, is the first step you told me the way how I test the motor?

AmeenTrainGuy posted:Yes, the long explanation I gave with pictures are the steps to test the motor. Just unplug the wires and test the motor using a DC power source between 9v and 15v.

Oh so just test the motor itself I gotcha

Time vs effort, at $24 I'd strongly consider that board. (after your confirmation of the motor not being damaged -the possible root cause for board issues). You may need both motor and board, save on shipping finding out now😉

After finding a bad motor, you may find the board still works. Scorched parts may or may not lead long lives after an overheating it's hard to say for sure.

Other engine boards controlling dc motors in other loco types may fit, and be a better choice, better motor responses, better sounds etc.. But the price of those will usually be higher. The lowest buck repair is the bridge rectifier, but, no dirrection change (except adding a sw. on loco), and possibly no sounds (depends on sound board and how it functions, as stand alone or how its tied to the main board beyond a simple power feed.

- So unplug the motor, jack up the engine by the ends so wheels can spin or lay it on its side, jump 9-15v dc power to the motor plug. Also turn it by hand at the flywheel feeling for tiny parts inside clicking or hitting vs smoothness . It may encounter some magnetic pull in spots too, that would be normal. Clicking and sharp hang ups of mechanical issues inside would not be normal. (brush arms)

- to check very well, if you use a power supply and run it for while jacked up that's even better.

- Why-Sometimes brush arms can seem ok, but change shape once things warm up causing mechanical issues inside the can motor. Rare but happens.

Don't toss the old board if you buy another. Other things can be used off of it eventually, or it may be repairable as a spare, or possibly even "hopped up" so it becomes better than the originals. Three options of three price ranges and three periods of time.... how fast you want it done is a factor too. Mostly folks want it done yesterday. I usually am happy with "eventually" and learning a thing or two.

Adriatic posted:Don't toss the old board if you buy another. Other things can be used off of it eventually, or it may be repairable as a spare, or possibly even "hopped up" so it becomes better than the originals. Three options of three price ranges and three periods of time.... how fast you want it done is a factor too. Mostly folks want it done yesterday. I usually am happy with "eventually" and learning a thing or two.

What about those ERR boards can I just use that or is that just for sound only

AmeenTrainGuy posted:TheRoyalHudson988 posted:Adriatic posted:Don't toss the old board if you buy another. Other things can be used off of it eventually, or it may be repairable as a spare, or possibly even "hopped up" so it becomes better than the originals. Three options of three price ranges and three periods of time.... how fast you want it done is a factor too. Mostly folks want it done yesterday. I usually am happy with "eventually" and learning a thing or two.

What about those ERR boards can I just use that or is that just for sound only

Yes, you can use those, although that will cost more. If you are looking for coupler, sound, light, smoke, and motor control, prepare to spend around $200. I would just go for the original board must more cost effective, unless you specifically want TMCC or cruise control.

I’m going to be moving to TMCC and legacy soon I mean I have the things needed to to that. But I’m just gonna keep her in conventional just for a little longer until that big day comes. By the way do they sell O gauge locomotive rollers on amazon?

Ok please don’t move on to the second step because I’m still getting the stuff for the first step

Everyone I just heard that Lionel are making new 0-6-0s take a look😀 it’s in their new second catalog for 2019. Page 72 in the lioncheif section. http://catalogs.lionel.com/19c2/

Ok I’m ready for the next step. I didn’t buy the board but I got the he micro mark rollers it seems easier then the circuit

Attachments

AmeenTrainGuy posted:That tool will help you countless of times. The more tools you have the better.

The next step requires you to isolate the motor electronically. Make sure the board and the motor are unplugged form each other. We don't want to ruin the board trying to test the motor. Once done you will have to find some alligator clips or a solid pair of wires.

So do I just unplug it with my hands or do I need something special so I don’t break it

AmeenTrainGuy posted:TheRoyalHudson988 posted:So do I just unplug it with my hands or do I need something special so I don’t break it

Use your hands to delicately remove the plug. Do not use the wires to pull on the plug. Make sure you grasp the plug itself and tug gently.

Before I go ahead and do that just double checking. Are you sure I use my hands because that sounds a little scary😰😨

AmeenTrainGuy posted:Make sure power is off to the entire layout. Use your hands gently and try to release all the static in your hands by touching a metal surface before pulling it the plug out. It shouldn't be too scary, and you should get used to it. You will be doing this a lot more in the future if you want to further your reach in this wonderful hobby.

It sounds less scarier then it was before you explained it and thank you for doing that . And I want to make a business on doing these type of things so it looks like I must do this.

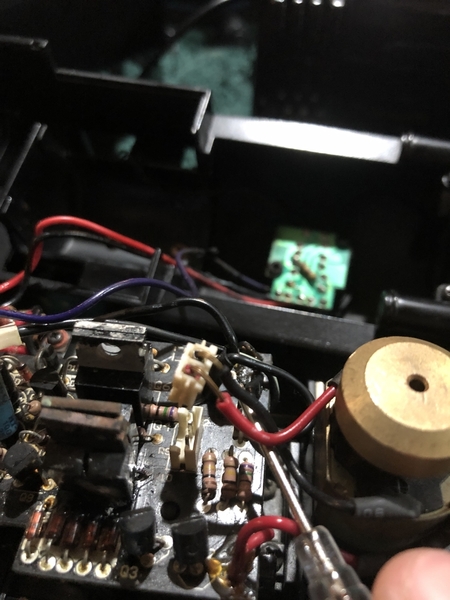

Attachments

Is that really bare wire at the connector? If those two touch, it would likely take out the reverse board!

Attachments

AmeenTrainGuy posted:Yeah, those wires cannot stay like that. That could be the reason why the thing is not running.

That’s how they came in thought connected like that

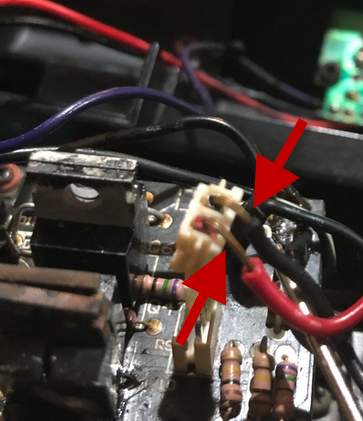

gunrunnerjohn posted:Is that really bare wire at the connector? If those two touch, it would likely take out the reverse board!

I don’t understand what you guys mean it came in like that when I got it 12 years ago. Nice to finally meet you buy the way I’m a subscriber of your YouTube

AmeenTrainGuy posted:See how the insulation is stripped from the wire at the bottom? That's quite dangerous to the board and the motor. It could be the reason why it's malfunctioning.

You mean they black and red covering in between the wire? Then yes

How do I cover them so no more Damage is being done?

(sorry I’m editing so much)

AmeenTrainGuy posted:See how the insulation is stripped from the wire towards the plug? That's quite dangerous to the board and the motor. It could be the reason why it's malfunctioning. If it's been like this for 12 years, that's most likely why your engine stopped working.

Oh maybe when it got burnt it must of ate away at some of the wires, you remember when I said that my train was burnt?

AmeenTrainGuy posted:I would replace the whole wire and plug assembly. That requires some electrical proficiency though. For now, try to cover at least one of them with tape. Test it first though before you apply this fix so that we can determine if the motor is dead.

Understood. First I will grab some lunch than I will get the 9v.

AmeenTrainGuy posted:TheRoyalHudson988 posted:AmeenTrainGuy posted:See how the insulation is stripped from the wire towards the plug? That's quite dangerous to the board and the motor. It could be the reason why it's malfunctioning. If it's been like this for 12 years, that's most likely why your engine stopped working.

Oh maybe when it got burnt it must of ate away at some of the wires, you remember when I said that my train was burnt?

Unlikely, I don't see any wire residue. The copper itself would be burnt if the insulation melted off. It looks like the plug was stripped while it was being unplugged since both of the wires are stripped.

I mean it could have been from the people who use to fix my train they could stripped the wire for something. I mean anything is possible.

It may have always been that way, but it needs to be fixed. ![]()

gunrunnerjohn posted:It may have always been that way, but it needs to be fixed.

Agreed

Ok I got electrical tape around the wires and some tape on top to hold it all together.

Attachments

AmeenTrainGuy posted:Have you tested the motor yet?

About the motor it’s still attached to the engine how do I physically remove it without breaking it?

AmeenTrainGuy posted:Connect to wires to the 9v battery first. Then run those two wires to the motor wire/terminal.

Ok got my 9v so which wires do I connect it to

AmeenTrainGuy posted:Connect the two wires to the terminals on the battery. Each terminal gets one wire.

Ok what do you mean by the terminals like the wires on the plug or something else? I have my 9v and I just don’t know which wire.

Attachments

AmeenTrainGuy posted:

Not my picture, but that's how it should look like. The color of the wire doesn't matter.

Which two wires do I use on my locomotive, is it the ones on the motor? I’m sorry I’m just a little confused

AmeenTrainGuy posted:I would get two wires, any wires you can put your hands on. From there, I would connect to the battery and then connect to the motor. It would look something like this:

Just without the black potentiometer. Again not my photo.

Oh so I just need a random wire from anywhere

AmeenTrainGuy posted:Just without the black potentiometer. Again not my photo.

Actually, that looks like a fuse holder. ![]()

so this week or the next I’ll buy some loose wires but do you have anything to recommend me a type of wire that can work with this

Yikes! For model train work, the internal wiring is typically #22, #12 wire is pretty difficult to work with.

gunrunnerjohn posted:Yikes! For model train work, the internal wiring is typically #22, #12 wire is pretty difficult to work with.

So which one should I use

22g or larger.

Too small of a wire gauge will risk overheating from excessive current.

There are not a lot of concerns with oversized wires; consider larger to be "safer" 99% of the time. (signal/sound reproduction it becomes more relevant).

fyi, I have dropped my net service because NO provider can get a decent signal to me all of a sudden; I will check in when I can though ![]()

Terminals are the metal tabs that wires connect to.

Any "random wire" sounds scary; it needs more context.

Disconnect one or more of the motor wires. This isolates the motor from board.

Now jump power to the 2 motor terminals using 22g or larger wire....or jump with a butter knife, screwdriver, or other metal if you have no wire.

Positive or neg. to which motor tab?; it wont matter. Reversing +/- just changes direction of motor here. Test both directions ![]()

So should I get them with alligator clips also so it makes things easier

Ok

Is #22 wire thick or thin