@coach joe posted:Boy, Peter you've made great progress. Anyone in the build crew have experience with the lift gate?

No.....but I am fortunate to have very saavy and skilled friends....

Peter

|

|

@coach joe posted:Boy, Peter you've made great progress. Anyone in the build crew have experience with the lift gate?

No.....but I am fortunate to have very saavy and skilled friends....

Peter

@Putnam Division posted:Update on the timeline.....

1. I will know this week when the Mianne Benchwork will be arriving......likely by the end of the month.

2. I acquired a layout-essential supply....pigtails for wiring.

I will put an update this week after I talk with Tim. I have used the time to arrange the storeroom. I have also dropped two Pilot/SUV-sized loads of trains to Cabin Fever in PA. I have worked on my inventory list.

I have taken the delay in stride.....everything that I'm doing in the layout room is probably easier done without the chaos of a layout build going on......However, the gang in Midlothian (Richmond) are getting excited to help me put the benchwork up. It was March/April of 2011 when the modular group gang helped me put together the Mianne Benchwork for my 6x16 layout.....and they are looking forward to a rematch!

Peter

Yes! I like those GarGraves pig-tails as well. Pricey though, aren't they?

George

Peter,

Just caught up on the thread. Man, it's looking great! You've made significant progress.

George

OK! Here's the latest Update......everything took a pause....my son got married in Philly on the 14th and I had Rufus for a week.....Rufus has been delivered back to Philly.....and, things can start up again.....

I finished building the Mianne Benchwork frame. As I said, I have not "motorized" the Lift Gate......that will come when I have the guys over to help with the plywood decking.

Here are the final structure assembly pics....the Lift Gate went up easily......

Have a great day!

Peter

Looking awesome Peter!

The before and after pics are going to be amazing. Heck the before and up to now is amazing.

I can't wait to see this one finished .... I mean further along. lol

Excellent progress, Peter!

Chris

LVHR

Exciting stuff Peter! Keep it coming.

Dave

WOW Peter. Looks great.

Congrats on your son's wedding too! ![]()

Bob

Looks great Peter. I hope my benchwork comes soon. It is supposed to be shipped out this week.

Peter, just caught up. Wow! Excellent space and overall plan. Not surprised at all. Things are really coming together at a nice pace too. I’m bookmarking this thread…

Andy

@jeffrey37 posted:Looks great Peter. I hope my benchwork comes soon. It is supposed to be shipped out this week.

From what you said, Jeff, I am assuming that you are also going to use Mianne. Here is a tip that I realized after the fact last time......

4x8 isn't really 4x8....it's more!

For example: if you put a 4x8 Mianne configuration together, it is 4x8 from the center of the vertical supports.....there is an extra 1 and 3/4" in the north/south, east/west direction.

I am going to take advantage of this and with good quality 1/2" plywood, go about 1and 1/2" over in each direction.

Peter

Thanks Peter. I was going to order the plywood before getting the base put together. I am glad you showed me this. Now I will wait and take some good measurements.

Peter, the benchwork looks great, as do the shelves full of trains.

@Putnam Division posted:OK! Here's the latest Update......everything took a pause....my son got married in Philly on the 14th and I had Rufus for a week.....Rufus has been delivered back to Philly.....and, things can start up again.....

I finished building the Mianne Benchwork frame. As I said, I have not "motorized" the Lift Gate......that will come when I have the guys over to help with the plywood decking.

Here are the final structure assembly pics....the Lift Gate went up easily......

Have a great day!

Peter

Looks great Peter. I ordered mine a few weeks back. Congrats on your son's wedding.

Peter looks great post a drawing of the track work and size of the layout if you can it will be amazing?

@Putnam Division posted:

Peter,

I recommend additional lower bracing (left to right in your two photos above). Mianne doesn't suggest this but I think it makes the table more sturdy and rigid. I have included it on both my layouts. You can see what I mean in this photograph of my 10'-by-5' layout table. I prefer legs to be braced in two directions. Just a suggestion and my personal preference... You can add it later.

Edit: As far as tabletop overhang, you can see that my layout has been built with 6-inch overhang on each side. Table plywood is 1/2-inch thick. Hasn't caused any problems at all, but I don't stand on the table.

MELGAR

@MELGAR posted:Peter,

I recommend additional lower bracing (left to right in these two photos). Mianne doesn't suggest this but I think it makes the table more sturdy and rigid. I have included it on both my layouts. You can see what I mean in this photograph of my 10'-by-5' layout table. Just a suggestion and my personal preference...

MELGAR

The wheels are a great idea too. I have them on my 6 x 20 and had to change out light bulbs last weekend and didn't have to climb on the table. The extra braces make it more sturdy if you have to move it with all the weight the layout will add. Great start either way.

@jeffrey37 posted:Thanks Peter. I was going to order the plywood before getting the base put together. I am glad you showed me this. Now I will wait and take some good measurements.

To illustrate what I mean a little better, I took some pictures with my 48" level....

1st, on a 48" I-beam.....

next, on a 36" I-beam....

Lastly, on a 24" I-beam......

That extra room that will be available for the layout will be great!

Peter

@MELGAR posted:Peter,

I recommend additional lower bracing (left to right in your two photos above). Mianne doesn't suggest this but I think it makes the table more sturdy and rigid. I have included it on both my layouts. You can see what I mean in this photograph of my 10'-by-5' layout table. I prefer legs to be braced in two directions. Just a suggestion and my personal preference... You can add it later.

Edit: As far as tabletop overhang, you can see that my layout has been built with 6-inch overhang on each side. Table plywood is 1/2-inch thick. Hasn't caused any problems at all, but I don't stand on the table.

MELGAR

I see what you mean....I have a few leftover 48" I-beams and I intend on using them....thanks, Mel!

Peter

This is the latest plan, which will no doubt have to be altered a little once I see how it works when the plywood is up.....

.....those are one ft squares, and, there is ~3 feet of clearance along the top and right..... with about 4-5 feet on the left and bottom.....the dormers on the left are not figured into the diagram.....

I've already adjusted the R side, because there is a 5 track 27" Ross transfer trable on order.....

Peter

@Putnam Division posted:From what you said, Jeff, I am assuming that you are also going to use Mianne. Here is a tip that I realized after the fact last time......

4x8 isn't really 4x8....it's more!

For example: if you put a 4x8 Mianne configuration together, it is 4x8 from the center of the vertical supports.....there is an extra 1 and 3/4" in the north/south, east/west direction.

I am going to take advantage of this and with good quality 1/2" plywood, go about 1and 1/2" over in each direction.

Peter

Great tip Peter. Thank you!

@Putnam Division, Peter, Wow, your making real progress, your bench work is really nice, well made, and more than likely easily assembled. Question, my reason to build with Grid construction was to have the ability to have valleys, rivers, mountains, also an easy way to have trains rise and fall as does actual earth. Are you going to have risers for grades, and if so, how will you attach them? I really like your plan and I do hope you are allowing wide radius to be able to run those beautiful articulated locomotives. Your train room is one of the best I’ve seen, Gunrunner John also has a super cool train room. Thank you very much for sharing the updates often, it’s going to be a fun to run model railroad. Your friend in Tennessee

Happy Railroading Everyone

@leapinlarry posted:@Putnam Division, Peter, Wow, your making real progress, your bench work is really nice, well made, and more than likely easily assembled. Question, my reason to build with Grid construction was to have the ability to have valleys, rivers, mountains, also an easy way to have trains rise and fall as does actual earth. Are you going to have risers for grades, and if so, how will you attach them? I really like your plan and I do hope you are allowing wide radius to be able to run those beautiful articulated locomotives. Your train room is one of the best I’ve seen, Gunrunner John also has a super cool train room. Thank you very much for sharing the updates often, it’s going to be a fun to run model railroad. Your friend in Tennessee

Happy Railroading Everyone

Larry......my plan is all on one level.......I am incapable of thinking in 3 dimensions.

Also, I am strictly an urban modeler.....no valleys, hills, etc. I hope to achieve changing elevations by varying the heights of buildings......and, I might enclose a corner or two in a tunnel with buildings/a city scene on top.

The Benchwork is customizable insofar that if you plan a river, canal or valley, Tim of Mianne, can selectively adjust the height of the I-beams to creat them.

So, to answer your questions, I am likely not a great source of information. I guess, if I was going to have grades, I figure that I would use the Woodland Scenic risers. Unfortunately, woodworking and carpentry is not a skill I possess.

Peter

Peter, looking at you open house post on Weekend Photo Fun it occurred to me that you are experienced with both, module construction and Mianne Benchwork. It seems to me that Mianne Benchwork would lend itself nicely to modular layouts. From what Mianne users post it is top quality and easy to assemble and re-configure or add on to. Not being a modular club member I don't see any negatives. Having experience with both I was wondering what you think about that.

@coach joe posted:Peter, looking at you open house post on Weekend Photo Fun it occurred to me that you are experienced with both, module construction and Mianne Benchwork. It seems to me that Mianne Benchwork would lend itself nicely to modular layouts. From what Mianne users post it is top quality and easy to assemble and re-configure or add on to. Not being a modular club member I don't see any negatives. Having experience with both I was wondering what you think about that.

Joe.....same answer as above:

I am neither a skilled nor insightful carpenter nor a woodworker......and, I lack the ability of thinking/visualizing things in 3 dimensions.

Peter

@coach joe posted:It seems to me that Mianne Benchwork would lend itself nicely to modular layouts. From what Mianne users post it is top quality and easy to assemble and re-configure or add on to. Not being a modular club member I don't see any negatives. Having experience with both I was wondering what you think about that.

Actually, I don't see Mianne benchwork as being all that appropriate for a modular club, and I am such a member, and I used Mianne for my layout. For transport, you have to take the legs off the module, or at least build in the ability to fold them. Also, Mianne is fine for a fixed layout, but the lateral strength is not nearly up to the of constant assembly/disassembly. If you apply a side force to a Mianne Leg, it will likely split the I-beam end it's attached to.

@Putnam Division posted:......my plan is all on one level.....

Also, I am strictly an urban modeler.....no valleys, hills, etc. I hope to achieve changing elevations by varying the heights of buildings......and, I might enclose a corner or two in a tunnel with buildings/a city scene on top.

Peter

Peter,

Please try to include some terrain height variation on your layout. You can still keep the tracks level for ease of assembly and constant speed operation. Many layouts are perfectly flat and, to me, look unrealistic. Even if you don't include hills and valleys, you can easily vary terrain height above the plywood with layers of 1-inch-thick extruded pink foam that is lightweight, and easy to cut and shape. In the real world, there is terrain both above and below the level of the railroad tracks. It is much more work to create valleys (below track level) but not difficult to include terrain above track level. You can get away with flat terrain in an urban area with street scenes. Take your time and enjoy the construction process.

MELGAR

Coach Joe,

I'm with Peter and GRJ as far as the Mianne frame is intended to remain in situ. However, on my smaller 4x8 layout that I moved to the basement, I asked Tim at Mianne to provide caster nuts with 3/4" deep threads to use casters instead of the leveling feet. The idea here is to be able to move the layout to accomodate activity in the area. To strengthen the framework I ordered four more 2' I-beams and six more 4' I-beams to tie together the legs on the bottom. This worked well, and I plan to put a sheet of 3/8 plywood over that level to store the trains. In the pic below, the center lower truss is left out temporarily to add some wiring under the layout. This kit is the same one Tim assembles in his video on the website, I just modified it to my liking.

As to my 8x16 layout in the making upstairs, no cross-bracing is desired, because I need the storage space underneath for tubs, and it won't be moved after the final construction is complete (famous last words).

Peter, John, 452, thank you all for the responses. Looking at Peter's two posts just set off the idea in my mind so I figured I would ask and wouldn't you know I got answers.

Peter,

When you install the Gargraves pigtails, how far apart will you place them? Thanks to your post, I now know of their existence. No need to scuff up the rails and no soldering. That is the best way to go. And yes, they are a bit pricey, but like the Mianne solution they are worth it. I'm planning on using terminal blocks and wire nuts. Hey, if my whole house is wired that way, why not the layout?

@452 Card posted:Peter,

When you install the Gargraves pigtails, how far apart will you place them? Thanks to your post, I now know of their existence. No need to scuff up the rails and no soldering. That is the best way to go. And yes, they are a bit pricey, but like the Mianne solution they are worth it. I'm planning on using terminal blocks and wire nuts. Hey, if my whole house is wired that way, why not the layout?

My gut tells me about every 5-6 track connections with more in an area where there are many turnouts.....

In reality, using a voltmeter and using as many as I need to ensure adequate power. What I said above will likely come close.....

I would welcome the comments of those more electronically astute....

Peter

Plywood ordered.

Plywood delivered.

Plywood in the attic!

I even have a left over pallet......

9 sheets of 1/2" 4x8 sanded birch plywood.....

We are moving steadily forward!

Peter

Cool, break out the saws, sanders, and routers, time for some benchwork! ![]()

![]()

And STILL no loop of track and a train running in circles........![]()

Getting all that plywood upstairs must have been fun.

Bob

Great project fun ahead Peter!

With the price of wood today, did armed security guards follow the delivery truck to your home?

Oh yeah, I wish I could help guide you with your wiring questions but instead of being "electronically astute" I'm more like electronically astupe.

Looking forward to following your progress

Popcorn in the microwave now...

Dave

Now wait a minute, Peter. Its not an attic anymore, its a "Train Room"!

@gunrunnerjohn posted:Cool, break out the saws, sanders, and routers, time for some benchwork!

Don't forget the shop vac for the saw dust....🤪🤪

Wow Peter, you’re moving right along. Very nice. I hope you had some help moving that plywood. I like your track plan too. The transfer table will be a great feature.

Andy

Peter nice progress!

Great Job PETER!!! Can’t wait to see it all done and trains running.

@Steamfan77 posted:Wow Peter, you’re moving right along. Very nice. I hope you had some help moving that plywood. I like your track plan too. The transfer table will be a great feature.

Andy

Andy......I turned 69 on June 7th......I hired two college kids to bring it up 3 flights of stairs.......

Peter

.......hoping for a delivery from Ross sometime this week!

Peter

@Putnam Division posted:.......hoping for a delivery from Ross sometime this week!

Peter

They always deliver Peter.

Happy belated birthday Peter. Good call on hiring the young, strong backs!

Andy

Happy birthday Peter, your layout will be awesome, thanks for the updates. Happy Railroading Everyone

WOW! Things are really looking good! I am with Andy and good call on hiring the young backs to do the heavy lifting!

I am just wondering where the elevator is located in the train room. I didn't see it in any of the photos and 3 flights of stairs would just kill me! LOL

@mike g. posted:I am just wondering where the elevator is located in the train room. I didn't see it in any of the photos and 3 flights of stairs would just kill me! LOL

Mike.......a regular day at home is always over 10,000 steps......and, I'm loving it!

Peter

Hi Peter, I am too much of a DYIer, but I think you made the right call to get help with the plywood. You are now officially a "house manager" with the motto of "I love work, I could watch it for hours"...

Plywood is one of mankind's greatest inventions, and when matched with toy train track, it is truly a match made in heaven.

Peter you are making great progress. We are impressed with the quality of the benchwork and your organization. The train room is beautiful.

I probably missed it but do you plan to use something like homasote to deaden the sound?

@Bill Webb posted:Peter you are making great progress. We are impressed with the quality of the benchwork and your organization. The train room is beautiful.

I probably missed it but do you plan to use something like homasote to deaden the sound?

Rossbed.......no screws (maybe one or two in certain areas) through to the plywood.......the glued scenery elements will hold it in place.

Peter

Peter, I applaud you for the 10,000 steps a day! I also get around that but for me the steps would just kill my knees!

Peter,

the next time you are in New York City you are going to have to make a stop inHighlands, N.J so we can do 10,000 steps together in Hartshorne Woods. You will love it. Enjoy every minute of building your layout.

5 to 8K a day is my average at work. Nice thing about working on a College campus. Good to have a stairmaster to the trains Peter.

Bob

Holy mackerel!!! ![]()

![]()

![]()

![]()

That is amazing progress! Well done, Pete!

George

A lot has happened over the past week.

1st......I receive noted of my credit card being billed from Ross Custom Switches. This arrived late Friday:

Time to paint.....a base coat of flat gray primer:

Base coat applied......

Then a veneer of textured gray stone.....

Peter

Looks like the box lids do a good job of keeping overspray from getting on the handsome sidewalk,

WOW Peter you're pulling out all the stops! Are you putting that under your full layout?

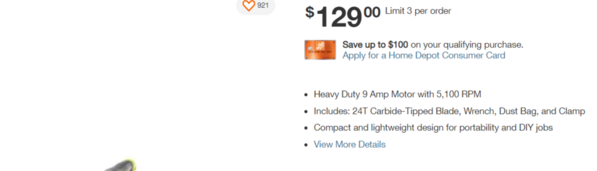

2nd.......a Ross track layout entails accurate track cutting......I was praticing on some Gargraves that I have......I had this cheap Harbor Freight chop saw ($30, ten years ago)......it was hard to sight where to cut......so much so that my nose was getting awful close to the cutting wheel to be able to see.

I was walking through Home Depot and saw this on sale for $68. I figure that it is less than an ER copay and has great visibility to sight the cutting line.....

Lastly, I have gotten a notice that the 27", five track Transfer Table from Ross, arrives this week. There is lots of excitement here!

That's why I started my next building project: the Yard Office that houses the key pad......by TW TrainWorx.....

Peter

@mike g. posted:WOW Peter you're pulling out all the stops! Are you putting that under your full layout?

The whole layout.......the stone spray is very close to the RC3R blend for blast: three parts coarse gray and one part coarse cinders.....

Peter

Great news Peter. The miter saw is a nice addition too, only $68.00? Really?

Bob

Peter,

You stole that saw! I thought it was a good deal.....

I cut all my Gargraves/Ross track with the $30 Harbor Freight chop saw, no problems at all.

@gunrunnerjohn posted:I cut all my Gargraves/Ross track with the $30 Harbor Freight chop saw, no problems at all.

Oh come on John.....can't a guy buy new power tools when the need arises???????😂😂😂

Next to new trains, they are my favorite purchases. 👍👍👍🤪🤪

Bob

Well, I bought that chopsaw for the layout build... ![]()

![]()

Very exciting time Peter. Have fun!

I told you that Ross delivers Peter. Your layout is going to be rocking with a transfer table and the yard office, as well as that chop saw chopping. I can't wait to see more.

Try to find a vacuum connection point with on your power tools or have some one follow the blade, sander or router as it cuts through the plywood. The saw dust can take over real fast before you know it.

Maybe drape some painters plastic over your many racks of trains.

Some tools have optional clip on vacuum attachment ports.

I run a Delta dust collector mounted on a furniture dolly near my cutting area.

* "Vacume" is a colloquial rendition. ![]()

Nice progress, and great deal on that saw.

You can add a miter saw laser guide to help with cutting the track for about $30. Here's a sample - https://www.amazon.com/Oshlun-...657121149&sr=8-3

I also looked up the saw…..quite a deal

Very exciting times Peter! The arrival of new supplies and tools = possibilities 😉

Glad you’re enjoying this so much, I know we are too.

Andy

Peter I have a question - May have been answered a while ago in the initial construction phase but - what exactly are you using for general room lighting ? How many lights etc. and what is the overall size of your train room ?

We recently made settlement and are in the process of moving into our new home in Charleston SC - I have a 20 x 21 foot room that’s going to be the train room

I am planning on building a layout and displaying trains on the walls similar to what you’re doing / I was thinking of installing 12 flush mount 6” LED ceiling lights (3000k) - 3 rows of 4 lights - this seems to be the go to amount from most lighting manufacturers - not sure if that’s enough or overkill ???

Just wanted to get your thoughts

Thank you

Joe S

PS Peter - everything you’re doing looks great / it’s so cool watching your build come together 👍🏼🚂

@Putnam Divisionn, Peter, it’s early evening here in middle Tennessee and it’s hot, seeing your accomplishments on your new (man cave) train room is so cool and relaxing. You have approached this fun to review project with foresight and proper planning, it’s going to be a fantastic train room. Thanks for the updates. Happy Railroading Everyone

@dorfj2 posted:Peter I have a question - May have been answered a while ago in the initial construction phase but - what exactly are you using for general room lighting ? How many lights etc. and what is the overall size of your train room ?

We recently made settlement and are in the process of moving into our new home in Charleston SC - I have a 20 x 21 foot room that’s going to be the train room

I am planning on building a layout and displaying trains on the walls similar to what you’re doing / I was thinking of installing 12 flush mount 6” LED ceiling lights (3000k) - 3 rows of 4 lights - this seems to be the go to amount from most lighting manufacturers - not sure if that’s enough or overkill ???

Just wanted to get your thoughts

Thank you

Joe S

Hard to describe…….I’ll take a picture over the next day or so and post it. I have dimmers.

Peter

Joe S,

Here is what I have in the train/guest room. My son-in-law is an electrician and this is what he installed. Recessed Halo dimmable LEDS wired to be controlled separately or together, meaning one side or both. Material obtained at Home Depot in a six-pack. They are spaced six feet apart from each other. The center "pillow" LED was the only light there originally. The room size is 18 x22' on a second floor.

Here is the control. HD didn't have a dimmable LED control, but I found it on Amazon. $67.

The slider is for the pillow light. Sorry for the crappy pic.

There will be a backdrop around the two walls adjacent to the layout, so no trains on display on the walls.

Son-in-law did a nice job, @452 Card

@dorfj2 posted:Peter I have a question - May have been answered a while ago in the initial construction phase but - what exactly are you using for general room lighting ? How many lights etc. and what is the overall size of your train room ?

We recently made settlement and are in the process of moving into our new home in Charleston SC - I have a 20 x 21 foot room that’s going to be the train room

I am planning on building a layout and displaying trains on the walls similar to what you’re doing / I was thinking of installing 12 flush mount 6” LED ceiling lights (3000k) - 3 rows of 4 lights - this seems to be the go to amount from most lighting manufacturers - not sure if that’s enough or overkill ???

Just wanted to get your thoughts

Thank you

Joe S

Lights on the stairwell……then the main room and then dimmed…..

Peter

@452 Card posted:Joe S,

Here is what I have in the train/guest room. My son-in-law is an electrician and this is what he installed. Recessed Halo dimmable LEDS wired to be controlled separately or together, meaning one side or both. Material obtained at Home Depot in a six-pack. They are spaced six feet apart from each other. The center "pillow" LED was the only light there originally. The room size is 18 x22' on a second floor.

When I moved in, I had a similar setup, but I found the lighting wasn't sufficient with normal bulbs.

I was actually looking at adding drops, but that's such a PITA that I did some more exploring. After several aborted attempts at replacing the bulbs, I came across these, that solve the problem. Talk about light! These suckers really light up the room!

Peter and 452 Card - Thank you for the feedback on lighting / really helps and much appreciated

I assume you guys are happy with your lighting ??? - I'm going to stick with my plan of 12 ceiling lights as the room is a little over 400 square feet

Thx again

Joe S

Thanks Mark!

Joe, I'm limited by the vaulted ceiling as to how many lights we could install, but the six I have plus the pillow seem to be just right. When they were installed, they were set at the lowest setting in the range. If necessary, they can be turned up brighter. (but not the pillow)

Now back to our regularly scheduled Putnam Division thread......

@dorfj2 posted:Peter and 452 Card - Thank you for the feedback on lighting / really helps and much appreciated

I assume you guys are happy with your lighting ??? - I'm going to stick with my plan of 12 ceiling lights as the room is a little over 400 square feet

Thx again

Joe S

I am.

Peter

That is an exciting delivery! Can't wait to see it!

@Putnam Division posted:Ross Transfer Table arrived today……..I’m very excited, and, things should get rolling, soon!

Peter

Peter. If you have some spare time, I wrote an article a few issues back about my Millhouse Transfer table. Not a ROSS but darn close. Maybe there are a few things similar.

Don

@3rail posted:Peter. If you have some spare time, I wrote an article a few issues back about my Millhouse Transfer table. Not a ROSS but darn close. Maybe there are a few things similar.

Don

Thanks, Don

Peter

Call the young men again to haul it upstairs! Congratulations!

@Putnam Division posted:

Now that is something of beauty. I have always been pleased with how well Ross products are packed. I know the first time I got a bunch of track in, I got nuts about the peanuts, but it was better that it was packed the way it was, than with minimal packing material. I used to work in shipping, so I know what flies, and what doesn't move hardly at all. I can't wait to see your article(should you write one as Don suggested) as well as it being popped on the layout when things start coming together sooner than later.

Great addition. Looks like you’ll be staying busy!

@Dave NYC Hudson PRR K4 posted:Now that is something of beauty. I have always been pleased with how well Ross products are packed. I know the first time I got a bunch of track in, I got nuts about the peanuts, but it was better that it was packed the way it was, than with minimal packing material. I used to work in shipping, so I know what flies, and what doesn't move hardly at all. I can't wait to see your article(should you write one as Don suggested) as well as it being popped on the layout when things start coming together sooner than later.

The packing is AMAZING!

Peter

Great news Peter, that will be a nice feature on the layout.

Andy

@Putnam Division posted:

I'm amazed that flat track hold soup! ![]()

![]()

I can see the smile on your face from here, that will be an exciting addition!

Exciting developments Peter. I haven't seen a soup tureen in years. My mother had one that she used all the time.

Bob

I'm sure that will look great once installed!

-Greg

Just catching up on this thread. It all looks fabulous! Very exciting to have cool stuff showing up!

BTW, I should be seeing that Altoona Model Works smoke stack shortly.

Keep up the great work!

George

Last week, we finished a summer's worth of work on the club layouts.........now, we started to work on mine! A lot of progress today!

Thank you Tom, Rick and Peter(a different one!)

I think we tired grand dog Winnie out!

Have a great day, folks!

Peter

Looks awesome Peter!

Looks like you'll be laying down track any day now!

-Greg

Wow, that's wide! How are you going to reach the middle?

Very nice ! Congratulations

Looks great Peter. Can't wait to see trains running.

Bob

@gunrunnerjohn posted:Wow, that's wide! How are you going to reach the middle?

John ……..I’m good with a step stool and if needed, the layout can hold me……..but the middle of the big area you saw will be pretty inert……all scenery.

Peter

Wow ... big, beautiful space and benchwork! ![]()

I like those flat cars with the armor loads on the display shelf. Winnie's moral support, too.

Looks great Peter.

@Putnam Division posted:John ……..I’m good with a step stool and if needed, the layout can hold me……..but the middle of the big area you saw will be pretty inert……all scenery.

Works for me, you sure have a huge area to play in, that's for sure! ![]()

@gunrunnerjohn posted:Works for me, you sure have a huge area to play in, that's for sure!

Speaking of scenery........![]()

![]()

Looks great, Peter!!

@Putnam Division, Peter, Wow, I’m so happy to see you working on your layout, (You have a great crew) in your beautiful train room, or man cave. I know your excited to see your new table work, plywood topping, and soon, trains will be running. It will be a room of so much fun, thanks for keeping us updated. @NYCJOE, #Gunrunner John each have beautiful layouts in the making, and now, you are bringing your amazing ideas to this fun to review forum. All I can say is Wow!!! Model railroading is a fantastic hobby, you All make it fun. Happy Railroading Everyone

Peter,

How are you attaching the plywood to the benchwork? Are you using the material from Mianne, or something else? Very curious about this because I'm stalled right now for that reason.

@452 Card posted:Peter,

How are you attaching the plywood to the benchwork? Are you using the material from Mianne, or something else? Very curious about this because I'm stalled right now for that reason.

We tossed the hardware from Mianne and used a brad nailer to securely attach the top. If you just attached it by the corners, it's free to vibrate on the I-beams as you run and create excessive noise.

Progress Peter, progress!

Looks great Peter! You guys don’t fool around, lots of progress in a short time.

Andy

Peter,

Everything looks like it's moving along. Before you know it you'll be laying track.

Dave

@gunrunnerjohn posted:We tossed the hardware from Mianne and used a brad nailer to securely attach the top. If you just attached it by the corners, it's free to vibrate on the I-beams as you run and create excessive noise.

Hi John, you are correct about the plywood vibrating on the I-beams. Tim from Mianne sells a special I-beam clip that works great. I’ve purchased quite a few for my latest rebuild.

@452 Card posted:Peter,

How are you attaching the plywood to the benchwork? Are you using the material from Mianne, or something else? Very curious about this because I'm stalled right now for that reason.

A little bit of everything......the Mianne corner brackets; screwing direct to the I-beams; small 90 degree L brackets to the I beams; and, small lengths of 1x3s and 1x4s to join the pieces of plywood together then they are juxapposed "in air".

You can see one of the many 1x3s in the picture below....

Peter

Thanks Peter, GRJ and Genemed!

Now I have a direction I want to follow. So many ideas here to consider. A wealth of info.

"Tim from Mianne sells a special I-beam clip that works great. I’ve purchased quite a few for my latest rebuild."

Is that part #3001?

To answer my own question:

Just called Tim at Mianne. The part # is 3002, .75 each. He is waiting for more to arrive, he has them custom made.

@452 Card posted:To answer my own question:

Just called Tim at Mianne. The part # is 3002, .75 each. He is waiting for more to arrive, he has them custom made.

Sorry for not responding quickly, I don’t always go to a topic for a bit. Yes, he was running out when I went to see him a few weeks ago.

Gene

Hello Gene,

What distance apart did you arrange the clips? Say, on a 4 ft. I-beam, or a 3 ft. I have an AR 8 x 16 with both 3s and 4s. The 2 footers I think should not count, at least for each one of them. Curious to know. This could become expensive!

Thnx

Hi, after all the corner clips where in place and tight, I went around from the top and checked for any loose movement where the I-Beams were and put a clip there. My method was just a couple taps on the plywood. You can easily tell the difference where the leg clip is. No special spacing, just used as needed to my satisfaction. My layout is 6x16 and I used 26.

Gene

@452 Card posted:Hello Gene,

What distance apart did you arrange the clips? Say, on a 4 ft. I-beam, or a 3 ft. I have an AR 8 x 16 with both 3s and 4s. The 2 footers I think should not count, at least for each one of them. Curious to know. This could become expensive!

Thnx

I forgot to mention, my layout was originally a 4x16 and I added the 2’ to the length. So there’s a short 2’ I-Beam on one whole side which obviously didn’t need any clips.

@452 Card posted:

Very nice. I see you have an access space in the middle. You may not need many clips. My problem was the long joints of the 4x8 plywood on the I-Beam on the 16’ side.

Peter, your progress is just Amazing! The outstanding work just shows how much skills you and your crew have! I wish I had folks around here to help me out with that many skills!

Once again Looking Amazing!

Not a lot done this week. We will finish the plywood and hopefully get the lift bridge motorized by the end of next week.

I have bought a gallon of brown paint the cover plywood. I put out some track to see if it agrees with the spot for the transfer table (it does!).

Lastly, I put the switches and special track pieces inside their roadbed.

Moving forward..........slowly......but, moving forward!

Peter

I'm always amazed when something I plan works!! I knew your transfer table location would work just perfectly!

Progress is progress, Peter - it all counts!

-Greg

Peter things are looking really good! Remember that slow and easy is the name of the game!

Looks great Peter. The track bed is sharp too! ![]()

Bob

Peter, sometimes something as simple as brown paint makes a big difference to the whole layout. It is the base layer that you work from. Any gaps in the ground cover will be shown as dirt (brown paint). The eye will not be drawn to it. The track bed looks good. Even gathering supplies is progress.

Andy

With the help of my good modular group friends......things are starting to roll!

1st, I needed another 3 ft I-beam for my transformer shelf. I had these extra cantilever beams which I no longer needed......I adapted two of them to become a new I-beam.

Last Friday, Tom (Gilly@N&W) came over and we finished the plywood decking. The Lift Gate motor was hung (but is not connected-a project for a future session).

This week, I will be sanding the edges; filling the gaps with plastic wood; more sanding; and then, painting the plywood with an earth brown color.

Peter

That’s nice progress, Peter! It is great to have good friends like Tom!

@Putnam Division posted:Not a lot done this week. We will finish the plywood and hopefully get the lift bridge motorized by the end of next week.

Peter

I can't wait to see the lift bridge which, IMO, is one of the biggest and most dramatic accessories.

Peter,

These are images of some serious craftsmanship. Thanks for sharing such an in depth documentation of your layout build, of what I am sure, will be a captivating layout.

Dave

It looks fantastic Peter. That is going to be a nice layout, you are going to rival the railroad barons.![]()

John

@Arnold D. Cribari posted:I can't wait to see the lift bridge which, IMO, is one of the biggest and most dramatic accessories.

Arnold......I am actually talking about the Mianne Lift Gate....which is generically a lift bridge....

Peter

Very nice, Peter. I agree with Dave "serious craftsmenship". This is just the beginning and one of the most important parts of creating a solid base for your layout. I will be interested in your next steps. Thanks for posting and keep it up. ![]()

No homasote??

Peter this is going to be a fun layout to watch. Excellent job on the foundation of the entire thing.

Things are starting to roll.

I taped (from below) all the seams so that paint won't bleed through. Large gaps got plastic wood......they'll need to dry before I can sand them (I need to be patient!).

Peter

@452 Card posted:No homasote??

I was very pleased with the sound control of the RossBed.......I don't plan to use screws except near the Lift Gate. My experience on the last layout was that it was pretty quiet and that the track doesn't move with the scenery holding it in place.

Peter

Exciting times Peter, exciting times!

Looking great Peter.

Peter,

I beg to ask, why no homasote?

Peter, that’s a great testimonial for Rossbed

Peter, thanks for the Ross endorsement.

FWIW, I used to use plastic wood in this application, however, early on I found that a Portland based feather finish like Ardex or Henrys feather finish product available at HD's flooring dept or any floor covering supply house troweled on easier, spread further to correct wide spread irregularities, dried hard, was easily sanded, dried quickly, and less expensive than plastic wood and had an indefinite shelf life if kept dry.

If at all possible please consider a layer of Homasote. It is an feature some may question, but you will never regret.

I would never build a layout without Homasote.

Peter, You may like to check with GRJ's layout build. When we did the Mianne lift gate we found some needed points that required extra attention.

John goes into detailed explanation on improving the control and correcting pulley/cable alignment and function. Great operating upgrade !

I found that subtle floor irregularities would throw off flush deck alignment. Short levels just did not pick up the end result of the slight irregularities. Multiple irregularities accumulate over a distance that ultimately affect a smooth flat consistent surface along the length of the joining edges.

As soon as I set an 8' level over the Mianne we noticed the source of the lift gate deck misalignment.

That Mianne lift gate is kind of nice but in some aspects it is a work in progress.

@Tom Tee posted:Peter, You may like to check with GRJ's layout build. When we did the Mianne lift gate we found some needed points that required extra attention.

John goes into detailed explanation on improving the control and correcting pulley/cable alignment and function. Great operating upgrade !

I found that subtle floor irregularities would throw off flush deck alignment. Short levels just did not pick up the end result of the slight irregularities. Multiple irregularities accumulate over a distance that ultimately affect a smooth flat consistent surface along the length of the joining edges.

As soon as I set an 8' level over the Mianne we noticed the source of the lift gate deck misalignment.

That Mianne lift gate is kind of nice but in some aspects it is a work in progress.

Thank you!

Peter

@Tom Tee posted:If at all possible please consider a layer of Homasote. It is an feature some may question, but you will never regret.I would never build a layout without Homasote.

I can attest to the benefits of Homasote! My main level is very quiet, my second level didn't get Homasote, and I'm kinda sorry I didn't adjust the build to add Homasote to it when I could. I solved some of the noise issue with butyl rubber sound deadening panels under the wood, but the Homasote would have done a better job.

John,

Would you kindly post a link to the lift gate pages?

Tom, the two pieces that are an addition to the stock liftgate install are these two upgrades.

The first is expanding the control switches to have one on each side of the liftgate instead of the single clumsy big yellow control.

The second enhancement to me was a major improvement in reliability of the lower limit switch. When you see the lame toggle switch and angle iron limit switch that comes with it, it's easy to see why they can get out of whack easily and cause a major issue with the cable unspooling. This only has to happen to you once to realize it's a big problem!

Finally, here's the diagram of the stock liftgate servo system for the curious.

Peter,

First rate work. Having some help every now and then is a boost too. The lift bridge is a nice addition.

Andy

Last week, I painted the plywood decking and started getting out the track.....

Since I got home from DC, I've been busy.....just to see where everything will go before we cut out for the Transfer Table and cut the custom sections.

Have a great day, everyone!

I am!

Peter

PETER - Layout progress to date looks great. Don't forget to think about access to all points on the layout. Those derailments are never seem to happen where you can reach them.

Your documentation by photos continues to be a great source of inspiration to us other O gauge railroaders.

Lookin' good Peter, you'll be running trains in no time! ![]()

Hi Peter, your table looks great! I am glad to see that perfect wye centered at the end of the table. You will put that into operation many times.

You may have posted a track layout configuration earlier. Would you post it again for reference?

@Freight Train Jim posted:PETER - Layout progress to date looks great. Don't forget to think about access to all points on the layout. Those derailments are never seem to happen where you can reach them.

Your documentation by photos continues to be a great source of inspiration to us other O gauge railroaders.

The hard-to-reach places will be "scenery only" ........I still might contract the static scenery on lift out.......I'll see down the road.

Peter

@Wood posted:Hi Peter, your table looks great! I am glad to see that perfect wye centered at the end of the table. You will put that into operation many times.

You may have posted a track layout configuration earlier. Would you post it again for reference?

Here you go.....

Peter

Looking good Peter. One question, are the windows UV blocking? Seen some cars down that way on the shelf.

@Putnam Division posted:

Thank you. That's a very workable setup. Lots of scenry space and lots of train action.

@Putnam Division posted:

Building a masterpiece of a layout like this: such excitement, creativity, hard work, joy, fulfillment.

We can follow Peter's progress and think back about all the positive things we felt when we built our own layouts. Arnold

@Wood posted:Thank you. That's a very workable setup. Lots of scenry space and lots of train action.

The large areas will be filled with city scenery. I can easily reach everywhere with a step stool.....it remains to be seen if I'l need trap door access.

Peter

Super exciting times Peter! Looks great!

Trains will be running before you know it!

Bob

Looking good Peter!

@Putnam Division posted:

Awesome Peter, love the roadbed cutting jig/tool. Also curious, I can't remember if you were going to ballast the track? Are you going to fill in the Rossbed gaps between the tracks even if you ballast the track?

Everything looks great. Pretty soon the New York Central(and other railroads) will be having trial runs to make sure that the track connections and electric are in perfect working order.

Peter,

What is the brand of that small handsaw you are cutting track with?

@452 Card posted:Peter,

What is the brand of that small handsaw you are cutting track with?

The picture with the Zona saw shows me cutting the foam RossBed. That is a 14.5' piece of RossBed which I'm cutting down to fit the 10" straight (then, I use the rest to outfit a 3" straight) ......to cut track, I use a Ryobi chop saw with a metal-cutting blade.

Peter

@Dave NYC Hudson PRR K4 posted:Awesome Peter, love the roadbed cutting jig/tool. Also curious, I can't remember if you were going to ballast the track? Are you going to fill in the Rossbed gaps between the tracks even if you ballast the track?

Everything looks great. Pretty soon the New York Central(and other railroads) will be having trial runs to make sure that the track connections and electric are in perfect working order.

I definitely will ballast.

Peter

Layout is coming right along! Fantastic!

It's coming along nicely! You've been busy lately! Interesting beverage holder..lol

-Greg

@Putnam Division, I see this thread is at the bottom of the list, so, I say, “WOW”, thank you for all the great pictures of Progress in motion, the brown paint certainly shows how hugh your layout is, it’s awesome. Have fun at York, stay safe, have a good breakfast at “Around the Clock Diner”, then go for the gusto at York, a train meet like no other. Happy Railroading Everyone

Looking good Peter. Coming along at a nice pace.

Andy

@Putnam Division posted:I definitely will ballast.

Peter

Peter, are you going to fill the gaps in the roadbed then?

@Dave NYC Hudson PRR K4 posted:Peter, are you going to fill the gaps in the roadbed then?

The ballast should…..if I think that gap is too wide….I’ll slice slivers of painted RossBed and fill the areas.

Peter

Post York with all the track and supplies I need....

Been up here working for about 3 hrs and it hardly looks like I've done anything......but actually a lot has been done. In medicine, we have a saying which is our response to the burden of computerization, "death by a thousand paper cuts"......

Well, the layout-building equivalent is Gargraves connector pin punctures. I'm sure everyone cringes a little thinking about them......![]()

I'm at a good stopping point for today.....here are some pics. I also what to say a big "thank you" to all the kind words and encouragement about the layout that I got at York. They are appreciated!

Have a great day, everyone!

Peter

Post York with all the track and supplies I need....

Been up here working for about 3 hrs and it hardly looks like I've done anything......but actually a lot has been done. In medicine, we have a saying which is our response to the burden of computerization, "death by a thousand paper cuts"......

Well, the layout-building equivalent is Gargraves connector pin punctures. I'm sure everyone cringes a little thinking about them......![]()

I'm at a good stopping point for today.....here are some pics. I also what to say a big "thank you" to all the kind words and encouragement about the layout that I got at York. They are appreciated!

Have a great day, everyone!

Peter

I'm watching with great interest.

MELGAR

Looking good Peter. Enjoy.

It looks great, Peter! Yes, I agree about Gar-Graves track joining pins.

Peter, were you putting in any sort of small bridges about the layout? I don't remember if you had said prior. Everything looks great, can't wait to see more.

@Dave NYC Hudson PRR K4 posted:Peter, were you putting in any sort of small bridges about the layout? I don't remember if you had said prior. Everything looks great, can't wait to see more.

No bridges, no elevations. When I design layouts, I can only think in two directions….

Peter

Hi Peter, really enjoy your updates! You seem to be really close to getting at least one loop of track up and running. Are you thinking of a target date for that. I don't think I could wait much longer.

@Former Member posted:Hi Peter, really enjoy your updates! You seem to be really close to getting at least one loop of track up and running. Are you thinking of a target date for that. I don't think I could wait much longer.

Dave.......no time limit.

I'm spoiled. Just got back from running trains at York. In addition, I have our three modular layouts 6x11 tinplate, 12x15 and 21x43 Atlas O to run on. There is an 11-3 "Halloween Open House" for the public this weekend.

Consequently, I am taking my time. I can stop when I come to an impasse and really think it through. When I'm tired, I can leave in for another day, etc. I can plan for "helpers" when I need them.

Once I get the track down in a generally complete configuration, it will be time to call for helpers. Time to install the Ross 27", 5 stop Transfer Table, make sure the track is straight, assign power and plan the overall wiring.

I am also spoiled that I have skilled helpers who are generous with their time.

In addition, I am currently President of our local modular group. Our busy time is upon us. Starting November 19th, we are committed every weekend (and some weekdays) for 9 consecutive weeks!

Peter

Peter

Another great update Peter.

It's a good thing you are retired and have all that "free time" on your hands. ![]()

Bob

@Putnam Division posted:No bridges, no elevations. When I design layouts, I can only think in two directions….

Peter

Is there no water on this purposed layout Peter? No lakes, no ponds, no river? I hope there's a water barrel somewhere collecting rain water if no other water is around. How will the livestock have anything to drink if there's no water? 😉

@Dave NYC Hudson PRR K4 posted:Is there no water on this purposed layout Peter? No lakes, no ponds, no river? I hope there's a water barrel somewhere collecting rain water if no other water is around. How will the livestock have anything to drink if there's no water? 😉

Magic! ![]()

Peter

@Putnam Division posted:Magic!

Peter

I see. Like the aluminum foil ice pond? My sister had taken a small ring frisbee, covered it in aluminum foil, instant iced up pond for Christmas. As a kid I thought that was the neatest thing I had ever seen. I think I was 7 or 8.

Peter, your layout is looking great! You sure have done a lot of work since my last visit to your updates! Everything is looking wonderful!

Peter, if I build another layout, all the track will be one level too

Maybe Peter is gonna sink a well for all his water needs.

I am at the point in track laying where I can set my distances from the layout edge and screw some pieces in......then, play off this configuration to do some custom-cut pieces.

Have a great Sunday, everyone!

Peter

Putnam Division looks great!!! I would imagine this has already been asked but what are your layout dimensions and what type of roadbed are you using?

Peter, things are looking great! That is going to be one huge layout! I am always impressed when I check in to see your progress!

@jjames9641 posted:Putnam Division looks great!!! I would imagine this has already been asked but what are your layout dimensions and what type of roadbed are you using?

The L is 14 by 22......the room is 20 by 30.

Peter

Peter, great progress. The track is going down at a nice pace. I agree with you. The next layout will be on one level.

Andy

Access to this requires an OGR Forum Supporting Membership