Thank you, Rich, Leandro, Bill!!

Rich, I'm glad you are reading through the thread. Thank you for the compliment on the good advice. I think the best advice comes from all of us pooling our knowledge. Some folks have expert knowledge in one area, others in another area, and sometimes getting different ideas from different folks lets me decide what is the best solution for my situation.

Leandro, sometimes I think I haven't done much, then I look back at the dates a page or two back and see progress has been made.

Bill, First of all, I hope your knee replacement went well and you are progressing well in PT.

I know the James River at the fall line quite well. I crossed the James River on the Boulevard (Nickel) Bridge going to and from work every day in 1976-77. I worked for Vepco at an office just off The Boulevard. Every day I had to go to the headquarters building downtown at 7th and Franklin to check things out at the microwave hut on the roof. Then crossed the James River to the System Operator office in Manchester South Side, then back to the telecom office. Those were the early days of telemetry, and the on site visit was necessary. So, I made 4 river crossings every work day. That said, I know what you mean, there isn't really an actual falls, just lots of small drops. If you stand in a stream like that and look upstream, you see layer upon layer of flat water with little drops in between. Based on what I did on the layout yesterday and just now, I think that is a good possibility here.

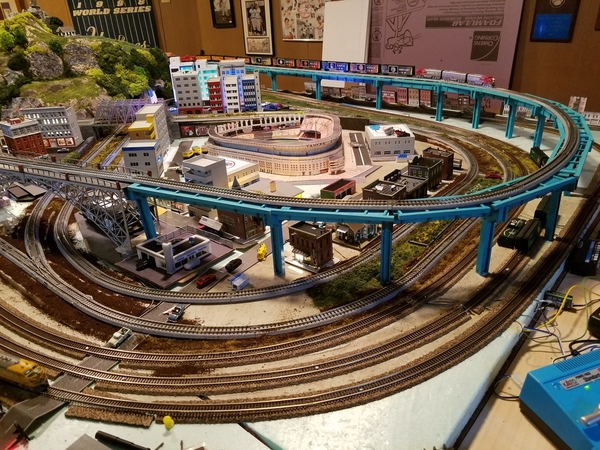

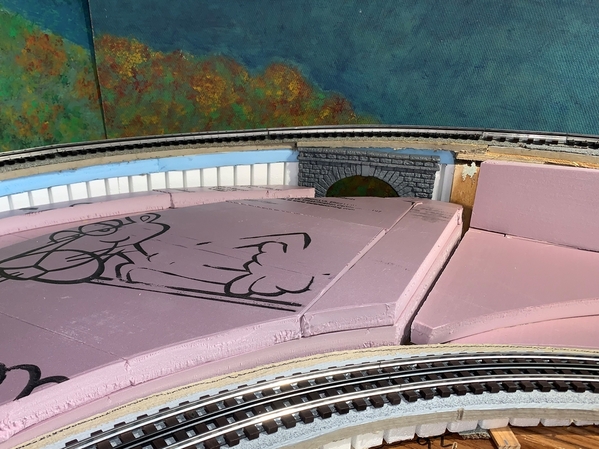

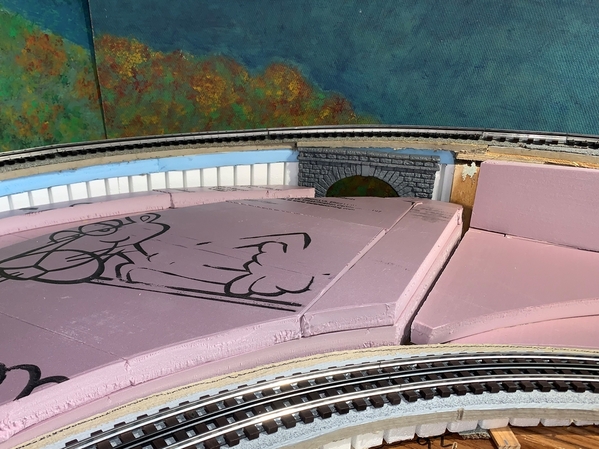

Yesterday, I looked at where I was going to have the stream pass under the upper track and to the backdrop. Here is the prime location in my opinion. I had a nice foam portal and wing walls that would nicely represent culverts on the prototype that let tributaries flow into the Black Fork. I cut it to size to look like this.

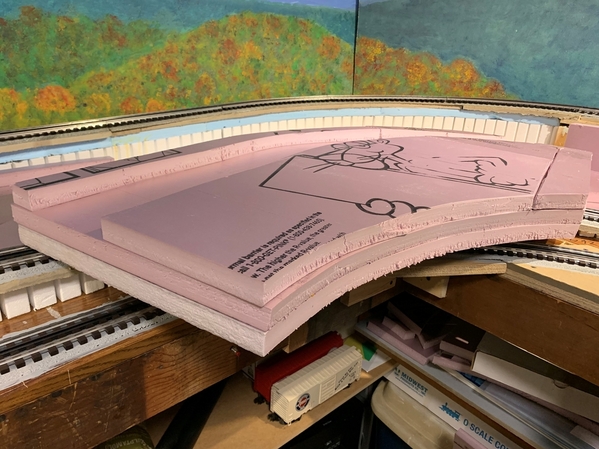

I knew it would be partially covered by the foam base for the scenery, but was disappointed it looked like this. I have trouble visualizing things. I have to do it.

Of course trimming the banks back would help, but not enough. Here are the other potential spots to the right of the one I planned.

The second photographs shows wires to the track above to the right of the culvert. There is another pair of wires for the other track and wires for the DZ1000 back there as well. That part of the scenery does need to be removable for maintenance only.

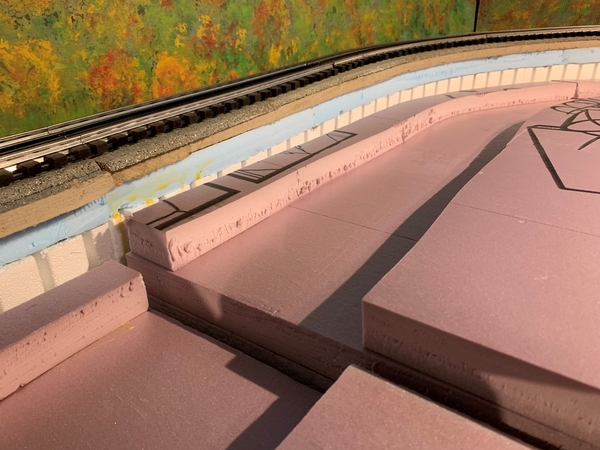

I ended up removing the extra section of foam that I added underneath two modules a few days go. This looks much better, and will look better still once I carve out the banks a little more.

In the last photograph, the stream will curve around and under the bridge and off the front of the layout with low banks.

Bill, to answer your question the intent was to remove these only for maintenance. A secondary thought was to remove them for actual construction. Actually, there is no reason to remove the one in the left of the next to last photograph, because there are no wires there. Yes, if I put buildings there, I could put lights in them, but the buildings will all be removable, and I'll put in plugs so the wires can be disconnected when removing the building. Here is the only place of concern on the module with the culvert.

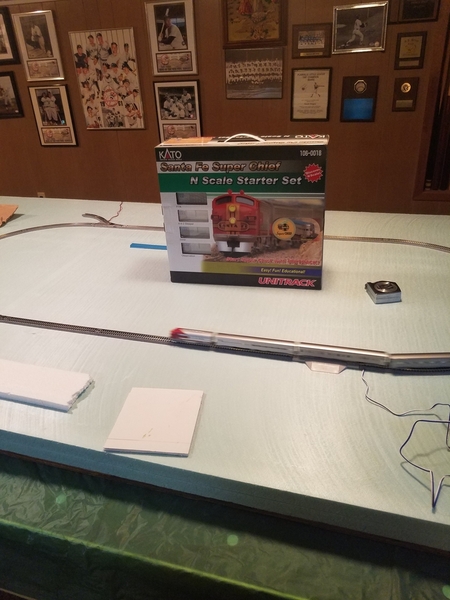

I could actually just make a small section of scenery removable to get at that. That would allow me to not have to worry the water area being crossed by a seam at all. Lots of folks say it is easier to work on scenery at the workbench, and then place the module on the layout. I am able to touch the backdrop at every spot while standing at the layout edge, so it isn't like I would be stretching over anything to build scenery in place. I don't have a workbench anyway. Here is my "workbench".

If I need more table space, I have to pull my wife's car out of the garage and set up a card table to work on. I don't know where I would store the module between work sessions anyway, except to move it back onto the layout and get glue and paint on everything while moving it. That isn't a good idea. So, I think I will just make small pull out sections of scenery where the wires are located.

At least that is the plan at this moment.