Thank you, Dave, Bob, Mike G, John, Mike Poncho!!

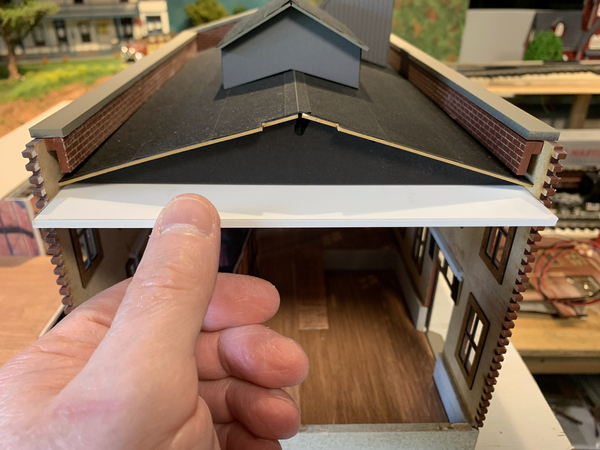

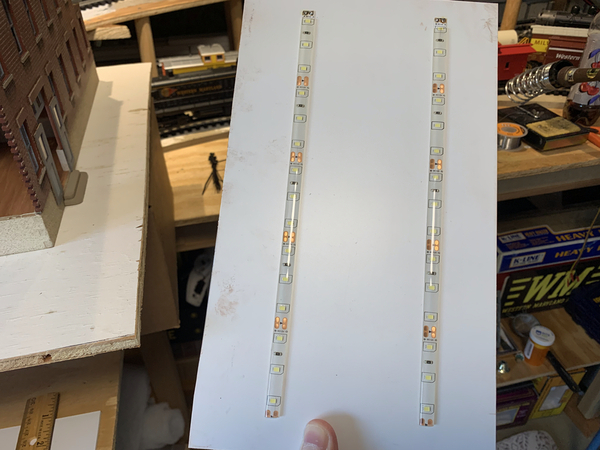

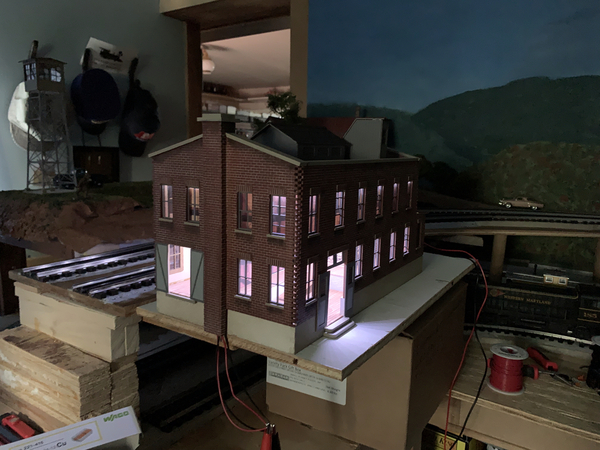

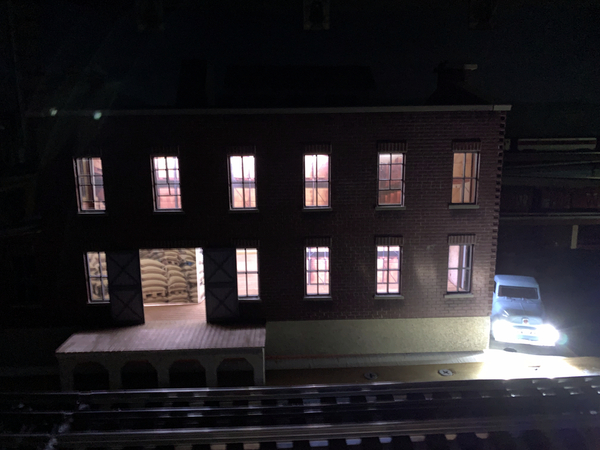

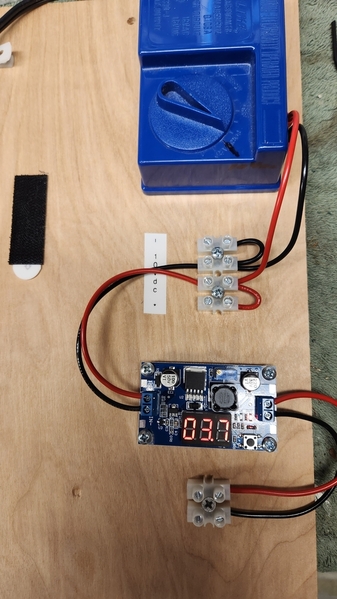

Yes digging out of a jam can be challenging, but rewarding when an idea starts to come together. I was short on ideas, but couldn't think of a way to describe the issues to ask for help on the Forum. The way the roof is inserted in this model being actually glued underneath the inner brick work at the top made it a given that I wouldn't be able to make it removable when the model was completed. Looking back, I think the ceiling was almost necessary to easily install the LED strips. Otherwise I would have had to support (hang) them on the thin roof trusses.

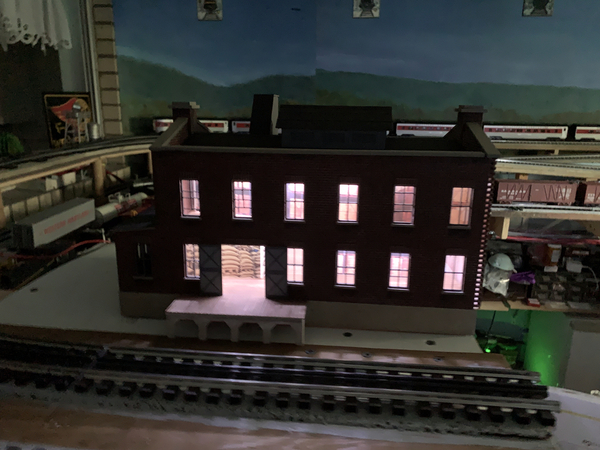

As I said before, Dennis Brennan did a great job of designing a kit that really mimics Frank Ellison's original, but with modern materials and techniques. Frank didn't provide an interior, so Dennis didn't either. I think the kit is great for someone like me who desires a basic building to make a start, and then each builder can add highlights, or additions either interior or exterior as desired.

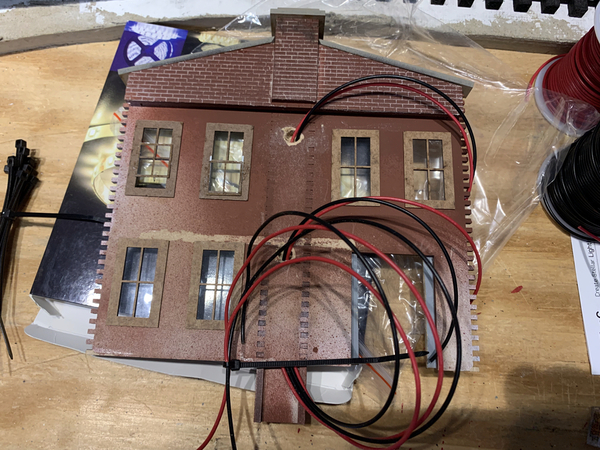

LT1Poncho Mike, I was thinking of using some kind of tape to seal off the light leaks. I had some idea of where they would be while I was building, but putting light inside is really necessary to find them all.

Now that I'm rested from some yard work, I hope to get back at the Sanky Wanky this evening.