I moved every 11 weeks for 5 years during college. I would love for my next move the last one you ever make. Then again, I say that now because my retiree neighbors are fantastic. They keep an eye on my place during the day and teach me how to tend the garden I started. Maybe I would feel differently if my neighborhood didn't feel like extended grandparents. I'm also not married yet. Hope I can find a girl that feels the same as I feel about my neighborhood.

Sheet & Tube had the Youngstown facilities (Brier Hill, Campbell Works, and the Rod and Wire mill in Struthers), the Burns Harbor Facilties, and some coke works in PA I think. I appreciate the Sheet & Tube works for the family connections I have as well as personal connections. (Pardon my rambling)

The Campbell Works were divided by the Mahoning River. That river basically splits Struthers and Campbell. Men from Struthers and Campbell worked at the mill and that boiled over into the Struthers-Campbell football rivalry. I'm a Struthers high school graduate. The mills closed in 1979 but we still hold that rivalry. There's a trophy for the winner and everything; it was the biggest game of the football season. It was good times.

My grandpa was the fire chief at Sheet & Tube. Him and another guy invented a way to refill spent fire extinguishers. I had uncles and cousins that all worked at the Sheet & Tube too. So I got loads of personal connection to the mill. My friends grandparents worked there with my grandparents and so on.

But that's enough rambling haha I'm glad model railroading lets me combine my love of history with my love of all things mechanical.

That poor 3D printer ran 24/7 from December 22nd to January 3rd while I was off work for the holidays and able to be home supervising it. The last piece is set to finish at 1AM tonight. Hopefully I can post some pictures tomorrow. I'll be looking for opinions on whether or not the stoves are too tall.

The coolest part of this project has been being able to create a fictitious city located in Mahoning County where the history lives on. The research has been a good time and I've met a lot of great people along the way before the pandemic messed things up.

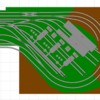

I attached a pic of the north end of the layout where the blast furnace is:

18 is a maintenance shop for rolling stock and the engines

17 is the boiler house

16 is the track leading down to the helix. Concealed under hill.

15 is the ore track that empties coal/limestone/iron ore from hoppers

11 and 10 are lunch rooms, called "canteens" where I worked

9 are the hoist engines for the skip hoist

8 is the blower house

5 are the blast furnaces including three stoves and a dust collector on the tracks.