Hi all,

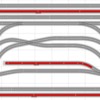

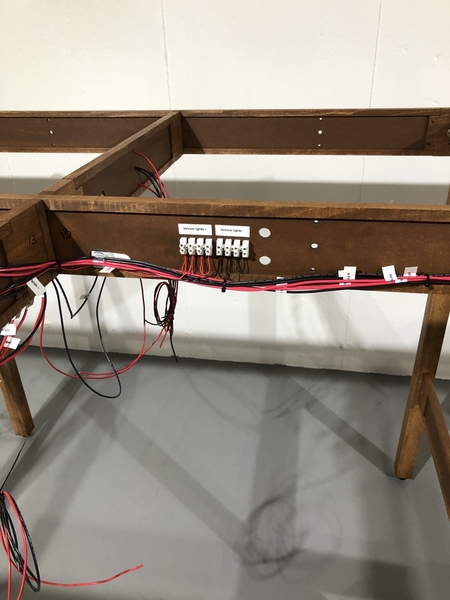

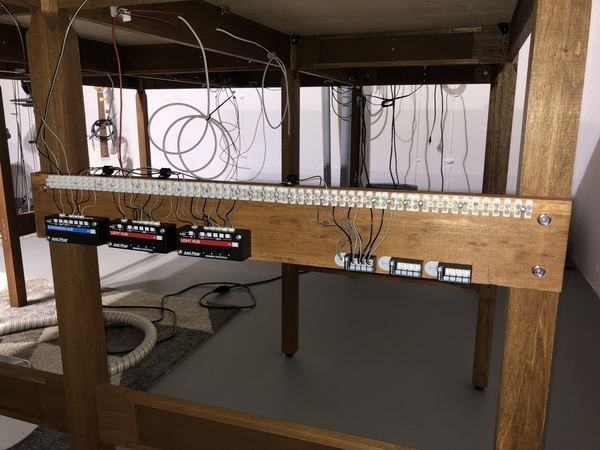

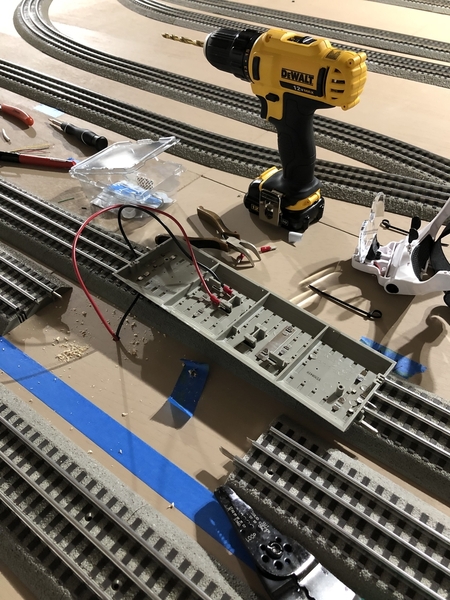

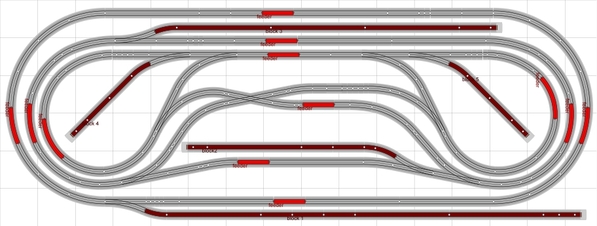

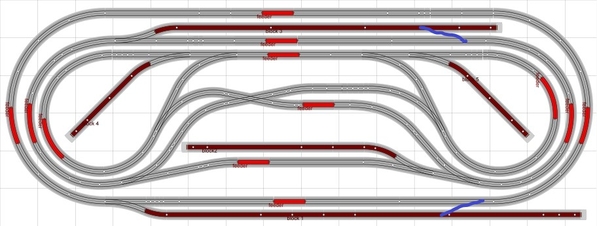

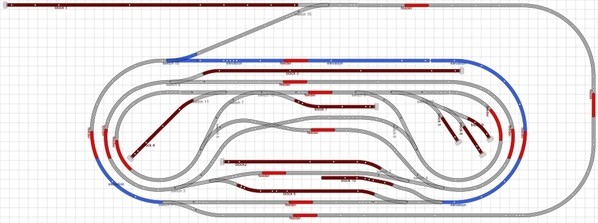

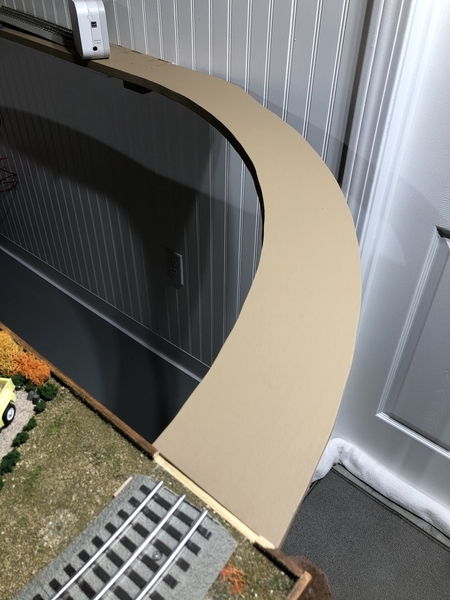

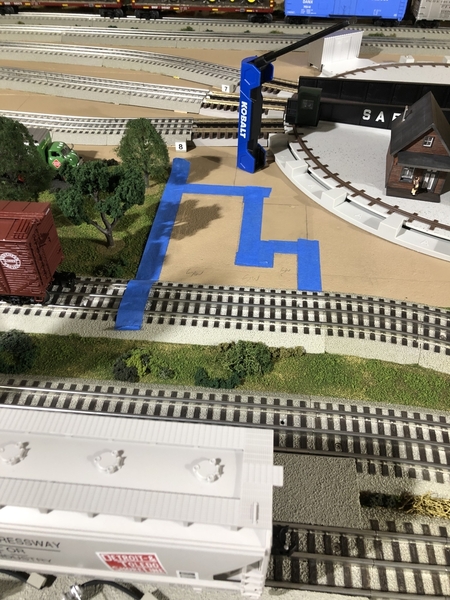

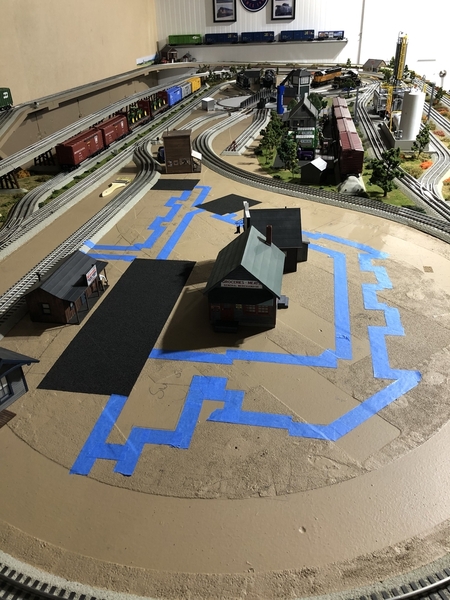

I’m in the process of rebuilding my layout I started last October to a 6x16. The extra 2’ in width from 4’ now gives me the option for 3 loops with long sidings. I’ve learned from my mistakes and figured it be easier to change now then complete the plan I had. This forum has been extremely helpful in me realizing what I didn’t know when I started. I’ll be picking up the benchwork extension from Mianne in a couple days. My first mistake was using 2” foam board instead of plywood. The pic is my initial design from Anyrail. I may elevate the outer loop, not sure yet. Another mistake I made (in my opinion) was ballasting fastrack. It just doesn’t look as good against the molded roadbed vs. other track without it. Also, what a pain in having to remove it!

Thank you for all the continuing knowledge in this forum.

Gene