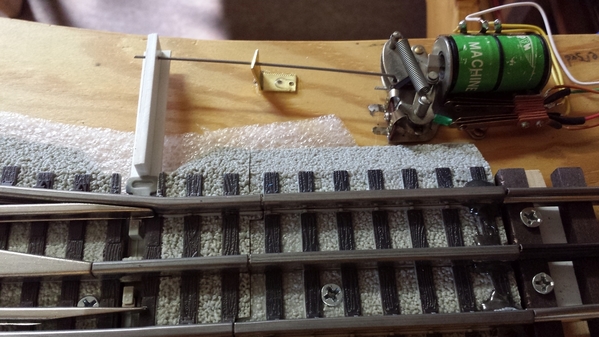

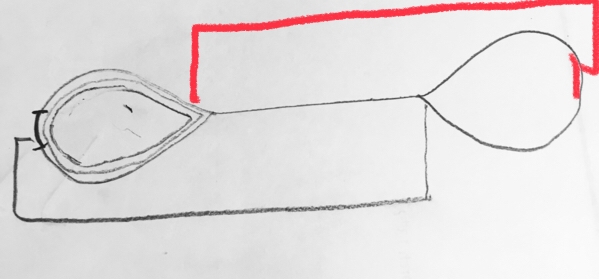

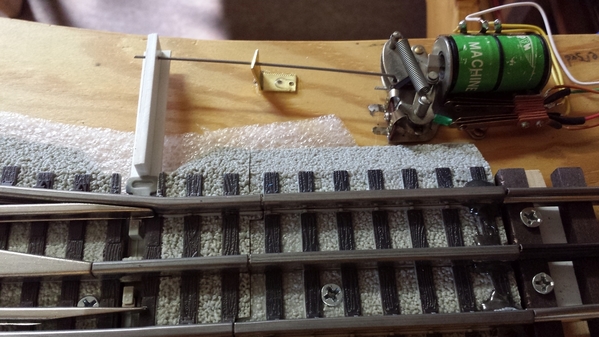

Here's how a low-tech approach might look. This is a manual switch I used my own motor on. Eliminate the motor, and you have a spring switch.

Wire is 0.039 music wire. The throw is styrene, glued to the original throw with Loctite's "plastic bonding system" (two-part, purple bottles, comes on a card) because nothing else I tried worked. Distance from the throw to the brass pivot is 1.5".

Wire is 0.039 music wire. The throw is styrene, glued to the original throw with Loctite's "plastic bonding system" (two-part, purple bottles, comes on a card) because nothing else I tried worked. Distance from the throw to the brass pivot is 1.5".

I have seven switches with this setup. I have often run the "wrong way" through these, and nothing derails. That includes modern cars with plastic trucks (metal wheels tho). If I were going to set this up to "groove the switch" as a normal thing, I think I would increase the length of the wire. As it is, it is very firm when closed - more than necessary, really.