Having an issue with the Strasburg #89 derailing on my Fastrack switches when set to the curve position. The pilot truck will follow the curve correctly, but the main drive wheels are picking the switches. It's not just one switch but pretty much all 22 of them. The flanges on the drive wheels are so razor thin and really shallow.

There is no gap between the switch points and the outer rail, so it not a switch points issue I can see.

Anyone else with Fastrack switches having an issue?

Thanks

Update: So, when I thought I resolved the issue with the derailing through Fastrack switches by switching to MTH tractions tires, I forgot to test pulling passenger cars.

Even though the MTH tires solved the derailing issue, the MTH tires are much thinner and have less traction when pulling the Strasburg passenger cars. I can pull 4 of the 6 cars up a grade with minor slippage, but not all 6. With 6 it can't make it up the grade. Using the Lionel tires, it can pull fine over the grade with 6 cars.

So, no good solution unfortunately.

Update: 6-23-23 - The engine is finally fixed due to all the people participating on this forum. My engine runs flawlessly through all my Fastrack switches now like my other engines.

In the end a few things resulted in the fix.

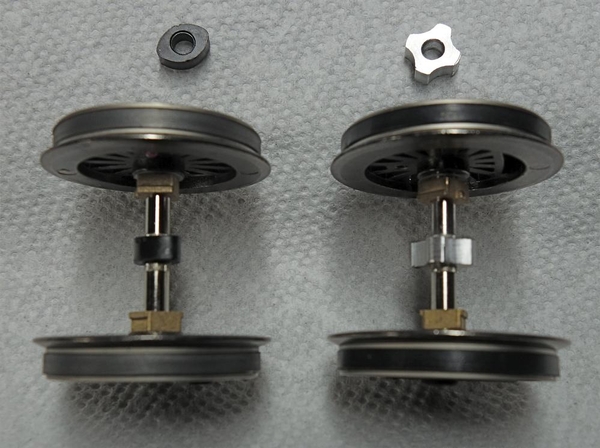

1. Swapping Front Wheelset & Rear Wheelset to move traction tires to the Rear.

2. Fixing jammed Front wheelset (was jammed into the frame and the bearing blocks had no movement in their slot unlike the rear. Axle was basically not horizontal.

Doing the above I was able to use Lionel Tractions tires which now allowed my engine to pull my 6 car Strasburg set up the grade.

Lionel's only current suggested fix is to use the different set of tires they will send you if requested (Generation 1 Mogul tires).

Regardless I would swap the wheelset for even better traction and also to make tire changes super easy.

Thanks to everyone for helping me resolve this craziness. Here is the final video which shows the disassembly and fix.