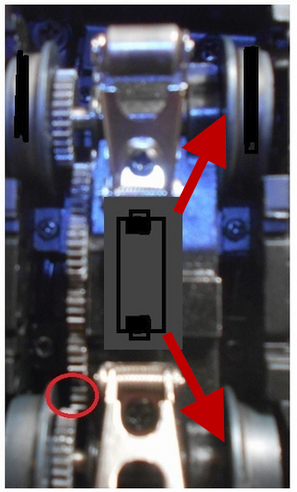

This was NOS, and it ran fine for about 30 days. I just found that the power truck (cab end) is locked up. I removed the truck and cannot turn the wheels.

Is there any way I might fix it? I can't see anything jammed in the gears (external) or the worm gear which seems fine. Am I just going to have to replace the power truck?

And- assuming I tried to run this briefly, before I noticed it was jammed, is there likely other damage, such as the motor? The LionDrive drive system is no longer used as far as I know. Is this a problem drive system??