There seems to be some controversy on the use of TVS surge protection for our trains. Here is my take on the situation.

Rapid voltage reduction on electromagnetic devices (devices with coils like motors or transformers) creates voltage spikes that can be twice or more of the nominal voltage. Noisy motors can also make voltage spikes (brushes on commutators). Spikes can also be introduced by lightning strikes on the power lines in the area. We regular use surge protected 120VAC power strips with surge protection built in so in most cases the power feeding our train power source is relatively clean from outside influences. But what about internal spikes in voltage. Apparently according to some who know the history of MTH’s DCS, their TIU includes TVS diodes to remove those spikes created by rapidly removing power from the system transformer. I assume Lionel does the same (??). So we are left with solenoids and accessory motors. (I will touch on the motors in the engines later) To isolate them I provide a separate power source and the AIU. The motors in the engines are controlled by a circuit board and are not directly connected to the tracks. Those of you running conventional variable AC to the tracks have the spikes problem and may well do to use TVS to suppress the spikes from the AC motors in the engines.

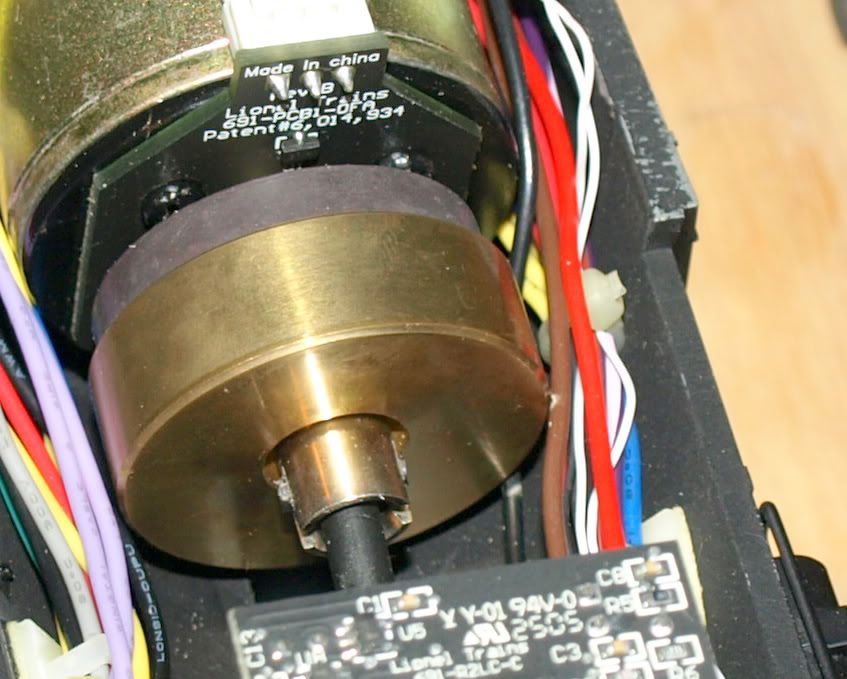

If you are using a DCS like system (MTH or Lionel) my guess is the circuit boards, if the designers followed good engineering practices, will have bypass capacitors on each and every circuit close to the circuit to filter out the spikes in the power to the circuit. TVS diodes are probably not necessary. The circuit design that controls the motor will have to include some protection from the motor generated spikes or the circuit will be short lived. No one is reporting failures like that so my guess is the circuit adequately protects the other circuits from motor spikes.

When it comes to suppressing errant fast spikes of voltage, the engineering rules of design dictate that you kill the spikes at their source so they don’t get broadcast as radio signals onto other nearby circuits. So any spike suppression needs to be done at the source, not every where else.

To re-iterate if you are using a digital control system then you are more than likely safe and probably don’t need TVS’s. But do isolate all the accessories from track power. UseTVS’s on solenoids or accessory motors to be sure. For those using classic variable AC power TVS are nice but there is little to no electronics in those old engines and there is no reason to protect what you don’t have. When operating a digital control system in conventional mode I have no idea how the circuits in the digital control system do that so I have no recommendation.

But if you are protecting an AC motor or solenoid from spikes using TVS’s then use them in pairs wired back to back across the AC lines. It does no good to only eliminate one polarity of spikes.

Now this is all my opinion and yours may vary. If you have scientific knowledge different from this or have experience different from what I imply then please speak up. My experience is base on my engineering background before there were TVS's available as components. Please add to this posting and don’t post hearsay or opinions with no scientific backing. I welcome knowledgable comments or criticisms.

LDBennett