Hi guys, as Mark said some really great projects getting done here! I took the time to write a comment on everyone's projects but that was before I was a page and a half behind and if I write everyone down there won't be room for my stuff! LOL

But I do want to call out a couple folks! I did hand out a ton of likes for all you guys and the great work your doing!

@Lionelski John, outstanding idea for an old soup can! It really turned out great!

@chris a Chris, the paving looks wonderful Thanks for the detailed explanation on how you did it as I have a few track crossings to do and will be a lot easier your way!

@idea-thinker, WOW That looks AMAZING! Your skills are just outstanding! I was going to ask the same questions that everyone else asked and was hoping your answer was going to be a kit! LOL

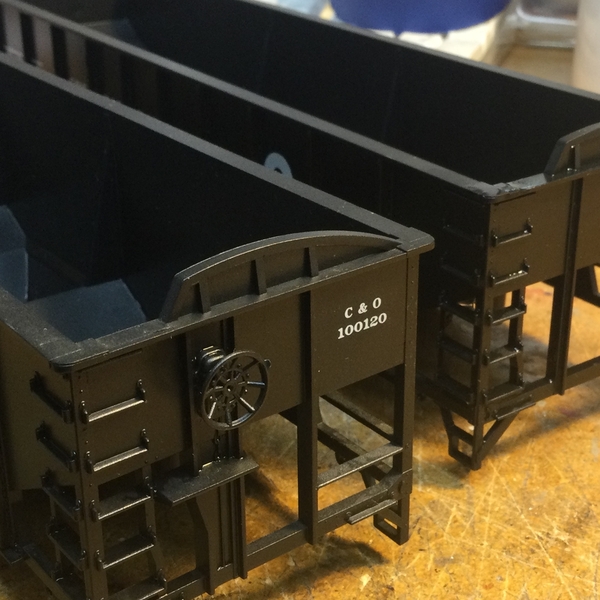

@darlander Dave, the 3 bay hoppers look great! I never heard of wash away. Thanks for sharing the information.

Well guys I didnt do anything in the train room yesterday or the day before as the son was here visiting. I figure I better get out there today as the daughter and grandkids are coming tomorrow

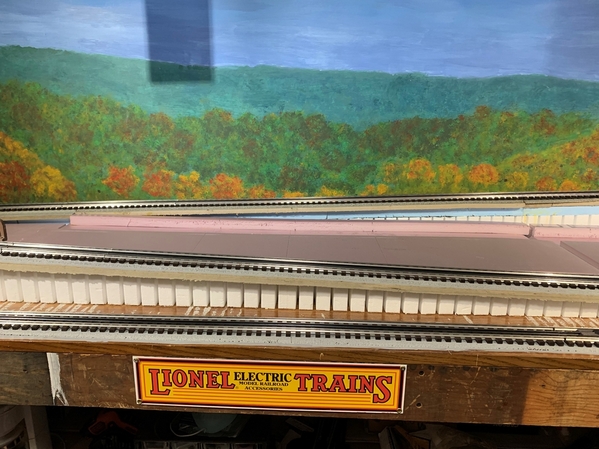

Well I worked on some more parking and a elevated road between the 2 upper bridges. I also reused the foam rock wall I carved when I first started, I will probably change it out down the road when I get better at stuff like that! LOL Here are a couple photos for you guys.

I hope to get a little time in the morning to try and work on the sides for the upper loop and the new parking lot area. I don't know when I will get to the road going over the door opening.

I hope you all had a great day and found time to have fun with your layout and trains!