My 022, powered with a 1033, was only throwing one way, so I used a spring to push the plunger in the direction it refused to throw (problem was not one I could fix properly, so I went with the mechanical solution). This was not sufficient, so I used a dime as a spacer, which was the only part on hand that did the job. It now switches back and forth repeatedly in a second, as shown in the video. Is the dime dreaming some sort of short?

Replies sorted oldest to newest

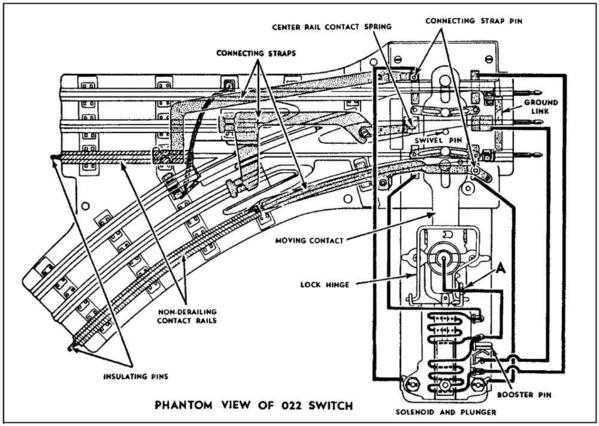

If you're shorting the center and outer connector on the switch together, whenever you try to switch it to the opposite path, it will immediately switch back. That's how they work! ![]() You have something parked on the non-derailing rail for the thru path, and obviously you're shorting the out path switch contacts.

You have something parked on the non-derailing rail for the thru path, and obviously you're shorting the out path switch contacts.

So any idea as to what is shorting it? My guess was the dime, but wrapping it in tape didn't solve the problem.

You probably do, but the simple questions need asked before it gets to complicated. Do you have the 2 insulating pins in place in the correct place. Did you try swapping the wires?

Gene Anstine

Gene is right, that would have been my next guess. ![]()

I have not rigged the controller to the transformer yet, the pins are in the correct place.

Something is clearly shorting the Out path control inputs. You may have to pop the bottom off the switch to find it.

It looks like in the video that the curve portion has the short unless when you put it on the curved section it does the same. One other quick check would be to make sure there is space and nothing touching where the very outside rail is cut. If it is, it's time to open her up and look for stray stuff. It would be located above the M in Moving Contact.

We have to rule out all the easy, obvious stuff. You shouldn't have to put a spring in or a dime, with a good cleaning and tune up these are good switches. I think you may have moved a wire inside the cover and caused the short. The right post could be hitting on the coil wire.

Gene

Attachments

Here is some stuff I have previously published that might help. Item 102 is pertinent to your situation; item 101 is some background info.

022 Switch Repairs Made Easy; 101

By far the most common problem with the venerable old 022 switch is the non-derailing function stops working, usually in the turnout position, but it can affect either direction. To repair this problem and many others herein will unfortunately require that the switch be removed from the layout.

The non-derailing feature uses a small section of electrically isolated outside rail in both diverging track paths. When a wheel set contacts this rail, the circuit is completed to the other grounded rail, and the switch throws in an instant to align for the oncoming train. This is the exact same philosophy as using an insulated outer rail section to operate various trackside accessories.

There is a flat metal tie bar on the underside of the switch base that is soldered to a lug on the curved insulated rail segment, and connects to the sliding 4 pole contact switch by means of a spring loaded stud. Unfortunately the solder joint is tiny and fatigue often causes the solder joint to break from the rail lug, and the non-derailing circuit ceases to function.

After removing the tiny screws that hold the bottom plate on and removing the bottom plate, simply re-soldering the metal tie bar to the insulated rail lug will get you back in operation. Or better yet, solder a short jumper wire between the tie bar and the rail lug. This makes the joint much more fatigue resistant. Be careful to not solder-bridge the two rail tabs together! This will cause the switch to want to be permanently aligned in that direction.

It is unusual for the straight through track to develop this condition, as it’s tie bar is crimped to the insulated rail segment. If non-derailing ceases to function in the straight direction, soldering the crimp connection will usually make it right.

022 Switch Repairs Made Easy; 102

Sometimes these switches develop a condition where the points are stuck in the turnout position, and any attempt to turn them straight results in a rapid “chatter” back and forth. Naturally when this happens, it will always be the switch that is the hardest to get to, and requires tearing up the most track to get it out! The usual cause is that the curved rail tie bar has become unsoldered (as above) and is touching the metal bottom plate. Thus it grounds out, which has the same effect as if a pair of wheels is connected between the outer curved rails, and the switch will always want to be in the “turnout" position.

Re-soldering as above will cure the problem. Additionally you should put a piece of paper or electrical tape between the tie bar and the metal bottom plate so that if it comes unsoldered again it won't short out. When new, 022 switches came with an insulating piece of paper inside the base plate, but alas, these tend to get lost over the years. It’s easy to make a replacement however.

Here are a couple of pix that show where to look for problems: Good luck!

Rod

Attachments

It refuses to open, apparently somebody stripped the bolts holding the bottom plate.

Rod Stewart posted:Here is some stuff I have previously published that might help. Item 102 is pertinent to your situation; item 101 is some background info.

022 Switch Repairs Made Easy; 101

By far the most common problem with the venerable old 022 switch is the non-derailing function stops working, usually in the turnout position, but it can affect either direction. To repair this problem and many others herein will unfortunately require that the switch be removed from the layout.

The non-derailing feature uses a small section of electrically isolated outside rail in both diverging track paths. When a wheel set contacts this rail, the circuit is completed to the other grounded rail, and the switch throws in an instant to align for the oncoming train. This is the exact same philosophy as using an insulated outer rail section to operate various trackside accessories.

There is a flat metal tie bar on the underside of the switch base that is soldered to a lug on the curved insulated rail segment, and connects to the sliding 4 pole contact switch by means of a spring loaded stud. Unfortunately the solder joint is tiny and fatigue often causes the solder joint to break from the rail lug, and the non-derailing circuit ceases to function.

After removing the tiny screws that hold the bottom plate on and removing the bottom plate, simply re-soldering the metal tie bar to the insulated rail lug will get you back in operation. Or better yet, solder a short jumper wire between the tie bar and the rail lug. This makes the joint much more fatigue resistant. Be careful to not solder-bridge the two rail tabs together! This will cause the switch to want to be permanently aligned in that direction.

It is unusual for the straight through track to develop this condition, as it’s tie bar is crimped to the insulated rail segment. If non-derailing ceases to function in the straight direction, soldering the crimp connection will usually make it right.

022 Switch Repairs Made Easy; 102

Sometimes these switches develop a condition where the points are stuck in the turnout position, and any attempt to turn them straight results in a rapid “chatter” back and forth. Naturally when this happens, it will always be the switch that is the hardest to get to, and requires tearing up the most track to get it out! The usual cause is that the curved rail tie bar has become unsoldered (as above) and is touching the metal bottom plate. Thus it grounds out, which has the same effect as if a pair of wheels is connected between the outer curved rails, and the switch will always want to be in the “turnout" position.

Re-soldering as above will cure the problem. Additionally you should put a piece of paper or electrical tape between the tie bar and the metal bottom plate so that if it comes unsoldered again it won't short out. When new, 022 switches came with an insulating piece of paper inside the base plate, but alas, these tend to get lost over the years. It’s easy to make a replacement however.

Here are a couple of pix that show where to look for problems: Good luck!

Rod

It does have the paper still, as it is visible under the plate. Cannot unbolt it though, as bolts stripped

Are you referring to the tiny flat blade screws?

The hexagon-headed screws have had their heads rounded.

You're going to have to get them out to get this working I suspect. Time for a Dremel tool to grind the heads off. ![]()

El Classico posted:The hexagon-headed screws have had their heads rounded.

Sometimes I have used a Dremel cutting disc to cut a slot for a screwdriver. If it breaks or still won't turn, just grind the head off. When I get the bottom plates off to service a switch, I just leave them off.

Rod Stewart posted:

I recently repaired the that broken tie-bar joint in most of my O22s. Shortly thereafter, one gave me symptoms similar to what EL CLASSICO describes...

022 Switch Repairs Made Easy; 103

Note the two sets of rail-tabs beneath the tie-bar. The set further from the switch machine-end (SME) is the correcting-rail; the set nearer to the SME is one of the grounded rails. In my case the grounded tab had somehow come into contact with either the tie-bar or the correcting tab. This was difficult to locate as the fault was hidden underneath the tie-bar. However, it was easy to resolve upon discovery.

As far as the screws go, I'd grind them off if nothing else works.

Regards,

The bolts needed a little force from WD40 to loosen them. Someone had soldered the ground rails together as well as to the tie bar. Broke it loose with a flathead screwdriver. Going to insulate it, then it should work fine.

Makes sense, that would screw things up! ![]()