S-GAUGE TRACK AND LAYOUT PLAN HERE.

O-GAUGE PLAN AT THE MIDDLE OF THIS THREAD.

S GAUGE BUILD IN PHASES AT THE END OF THE THREAD.

The passing track at the top makes the layout a better 2-train layout.

|

|

The passing track at the top makes the layout a better 2-train layout.

Replies sorted oldest to newest

Impressive, three reverse loops in a 5'x9' space. Nice design. Wiring the upper reverse loop with one PSX-AR-AC is easy and the reverse loop segment is long enough to hold a reasonably long train. On the lower elevation all the track making up the center"X" can be isolated and wired through a single reverse loop controller. Max train length through the "X" would be an engine and four cars if the last car is illuminated. Fortunately the S gauge 90deg FasTrack crossing has an insulated center diamond. Are you planning to build and operate this layout?

@AmFlyer posted:Impressive, three reverse loops in a 5'x9' space. Nice design. Wiring the upper reverse loop with one PSX-AR-AC is easy and the reverse loop segment is long enough to hold a reasonably long train. On the lower elevation all the track making up the center"X" can be isolated and wired through a single reverse loop controller. Max train length through the "X" would be an engine and four cars if the last car is illuminated. Fortunately the S gauge 90deg FasTrack crossing has an insulated center diamond. Are you planning to build and operate this layout?

Thanks AMFlyer, I am toying with the idea, I just now ordered some track to play with and a command control turnout.

Agree, the elevated reverse loop is straight-forward for detection and reversing.

On the lower section, I am not sure. Would it work to wire the oval in two halves horizontally, ending at the crossing. Then two reverse units would detect and reverse each half. That would handle longer trains?

Not sure about this, the yellow and green would both be subject to reversing on a polarity detection across the gap. Only one should fire, depending on direction of travel. May need some more thought.

I am thinking four reversing units total?

I worked up a circuit some years ago, to control a block signal that shows red when the two track sections are opposite polarity. Have not revisited the idea recently.

Or is this what I need: the black never reverses, but the green and blue reverse on a polarity mismatch. That would work if power is AC.

Ken, my layout has a hidden staging yard/reverse loop under the layout that looks just like your red plus blue track. Mine is wired such that the reverse loop segment, your blue track, would end at the point end of the upper RH turnout. I am not sure if four PSX-AR-AC's are necessary but what you drew should work. My concern is there are two reverse loops touching each other and I am not sure how the controllers will react.

I would first try combining the red and yellow and connecting that to the transformer. Connect the green through a reverser board and the blue through another reverser board. I think that works.

The advantage of the way I first suggested with the entire "X" as a reverse loop is that you can operate engines to move cars on and off the sidings without constantly triggering the controllers. When the pilot wheels move across that insulated junction there is a pretty big spark when the board is triggered. Not like the HO DCC system. 10A from a ZW-L channel can make a big spark, that is one reason why the AC version of these boards have such a big heat sink on them.

I have 5 PSX-AR-AC's on my layout and after four years one just failed. It is the one that powers the points/diamond in a 22.5deg mainline crossing. It is frequently activated because of the crossing location in the track plan. I have two new ones in the mail to me from Tony's Trains, a replacement and a spare. It is unusual for these to fail so I have someone who will look at the failed board to see what happened.

Hi Ken nice layout on your elevation could you tell me how many feet going from 0 to 4 1/2 inches and what height are the supports and spacing?

The length of the grade can be calculated from the 3.9% and 4.5" rise. That is almost exactly 10', plus some additional distance for the required vertical easements at the bottom and top of the grade. That would make the total grade between 11' and 12' depending on the easements used.

@AmFlyer posted:Ken, my layout has a hidden staging yard/reverse loop under the layout that looks just like your red plus blue track. Mine is wired such that the reverse loop segment, your blue track, would end at the point end of the upper RH turnout. I am not sure if four PSX-AR-AC's are necessary but what you drew should work. My concern is there are two reverse loops touching each other and I am not sure how the controllers will react.

I would first try combining the red and yellow and connecting that to the transformer. Connect the green through a reverser board and the blue through another reverser board. I think that works.

The advantage of the way I first suggested with the entire "X" as a reverse loop is that you can operate engines to move cars on and off the sidings without constantly triggering the controllers. When the pilot wheels move across that insulated junction there is a pretty big spark when the board is triggered. Not like the HO DCC system. 10A from a ZW-L channel can make a big spark, that is one reason why the AC version of these boards have such a big heat sink on them.

I have 5 PSX-AR-AC's on my layout and after four years one just failed. It is the one that powers the points/diamond in a 22.5deg mainline crossing. It is frequently activated because of the crossing location in the track plan. I have two new ones in the mail to me from Tony's Trains, a replacement and a spare. It is unusual for these to fail so I have someone who will look at the failed board to see what happened.

Many thanks for your help, Tom, I appreciate your experience and insight!

So, is this idea worthwhile to allow trailing-point switching of the spurs without tripping the automatic reverse units?

I divided the top green/black straight section in half, thinking either side might need a place to set out a car or two while interchanging with the spurs. The little curving tail past the spur's turnouts on each block, might allow a car or lighted caboose to be set out there, at 9.5".

The bottom green/black straight I assigned it all to the green block, in case a locomotive working the green spur with a short train needs some length to move a train back and forth while switching. The black block has the length on grade running up to the elevated that gives it more length/space to work with.

@AmFlyer posted:The length of the grade can be calculated from the 3.9% and 4.5" rise. That is almost exactly 10', plus some additional distance for the required vertical easements at the bottom and top of the grade. That would make the total grade between 11' and 12' depending on the easements used.

The run on grade from turnout to turnout is 110". I would use Woodland Scenics inclines for simplicity and ease of construction to make the grade. Their 4% grade is 8 feet, 96" (actually a bit over 4%, but close) with a rise of 4". The additional 0.5" rise requires another foot of run. So to reach 4.5" at 4% (approx), is 108 inches. No length for easements.

So instead, if I lower the rise to 4.25" from 4.5", then the run on grade needed is 96+6=102". Leaving 8" for vertical easements, which I would give equally 4" at the top and bottom, so there would be 8" at both ends at 2%. Perhaps not enough easement, but better than nothing.

Woodland Scenics has 2%, 3%, and 4" foam curve-able inclines. Its pretty easy to cut an 8" section of 2% for both ends, and run 4% in between.

4% is the maximum grade I will work with in O. I am thinking that will work fine for short S trains as well?

NMRA S Scale Vertical Clearance recommendation is 3 3/16" to 4 5/16", so 4.25" seems doable. From that 4.25" you must subtract the height of the roadbed and rail under the bridge, and the depth of any bridge support. Seems like that will be fine, in the middle of NMRA's recommendation. (Perhaps won't allow double-stacks ![]() ).

).

I am looking to purchase a LionChief Northern as the "big power" running this layout, needing S36 minimum.

In this version I added a tunnel to the mountain in the lower-right. It features a sheer rock face (dark color).

@Ken-Oscale posted:The run on grade from turnout to turnout is 110". I would use Woodland Scenics inclines for simplicity and ease of construction to make the grade. Their 4% grade is 8 feet, 96" (actually a bit over 4%, but close) with a rise of 4". The additional 0.5" rise requires another foot of run. So to reach 4.5" at 4% (approx), is 108 inches. No length for easements.

So instead, if I lower the rise to 4.25" from 4.5", then the run on grade needed is 96+6=102". Leaving 8" for vertical easements, which I would give equally 4" at the top and bottom, so there would be 8" at both ends at 2%. Perhaps not enough easement, but better than nothing.

Woodland Scenics has 2%, 3%, and 4" foam curve-able inclines. Its pretty easy to cut an 8" section of 2% for both ends, and run 4% in between.

4% is the maximum grade I will work with in O. I am thinking that will work fine for short S trains as well?

NMRA S Scale Vertical Clearance recommendation is 3 3/16" to 4 5/16", so 4.25" seems doable. From that 4.25" you must subtract the height of the roadbed and rail under the bridge, and the depth of any bridge support. Seems like that will be fine, in the middle of NMRA's recommendation. (Perhaps won't allow double-stacks

).

I am looking to purchase a LionChief Northern as the "big power" running this layout, needing S36 minimum.

Looking forward to seeing this built.

BTW, the FlyerChief Northern will run on R20 (original Flyer curves.) There is no so-called "S36" in S sectional track. The common curves are R20, R24 and R27. The "S36" is a result of Lionel's cut-'n-pasteitis from the O gauge FasTrack.

Rusty

I made two curved plate-girder bridges as approaches to a straight long steel bridge, on concrete piers.

Could be a long trestle instead, with a short bridge over the crossing and turnout.

i cant use the woodland incline because my incline is off the table im using angle brackets screwed to the side on the table it starts 36in on the table then goes on to the brackets with a piece of 1/2 ply under the fasttrack i can adjust the bracket height to what ever but i dont know what ever is i have trouble with percents i was looking for height /inches /length

thanks

Wayne: don't know if this helps: But just calculate 1/2" rise for each foot at 4% (close to 4% - 4" rise in 96" run - 8 ft).

If you want 2%, then 1/4" inch rise every one foot.

If you want 3%, then 3/8" rise every foot.

This is what Woodland Scenics uses, for convenience. The actual grade of their inclines at 4% is 4"/96" = 4.166% grade.

The actual for 3% using this "heuristic" (rule-of-thumb) is 3/96 = 03.125%.

Actual for 2% is 2/96 = 2.083%

If you are not concerned with the variance, this is an easy way to calculate and plan grades.

For instance, using these approximations, if you want a 4% grade with vertical easements of 2%:

So that gives 4.5" of rise over 10'.

[by comparison, 10' of constant 4% (actual 4.166%) gives 5" of rise. 10' of true/precise 4% grade gives a rise of 4.8"]

Years ago, I built a layout with a grade this way:

Total rise over 12' was 5 1/4" (for an O layout). I put two little 4-wheel "Beep" locos at the head-end, and they pulled 11 cars up the grade just fine. Fun times! That was the length of my passing track, so all good.

@Rusty Traque posted:Looking forward to seeing this built.

BTW, the FlyerChief Northern will run on R20 (original Flyer curves.) There is no so-called "S36" in S sectional track. The common curves are R20, R24 and R27. The "S36" is a result of Lionel's cut-'n-pasteitis from the O gauge FasTrack.

Rusty

I wondered about that, wondered if Lionel really tested or built the loco for 36" diameter rather than 40" diameter. But I didn't want to assume, so just posted what Lionel claimed on their website.

Thank you Ken now i have the numbers i can fix the elevation.

@waynef posted:Thank you Ken now i have the numbers i can fix the elevation.

Wonderful! Glad to help, and thanks for the discusson!

Ken, your redesign of the sidings looks good to me, it is quite well thought out. If I may, I have one more suggestion for your consideration. It appears almost all the action is around the center diamond. Consider making the oval and diamond the upper level and the long reverse loop with parallel tracks the lower level. This way none of the turnouts will be obscured and some nice industry and city buildings can be positioned around the sidings without being obscured by track and other viewblocks.

One other minor point, the rise to run numbers in an earlier post include some rounding which shortens the actual horizontal distance required. For example a 1% grade is .12" in 12", so a 4% grade is .48" in 12". A 4.8" rise requires a true 10' w/o any vertical easements. At 4% some Legacy engines and some AM engines will require a short vertical easement. I have them on my 2% grades for flawless operation.

@AmFlyer posted:Ken, your redesign of the sidings looks good to me, it is quite well thought out. If I may, I have one more suggestion for your consideration. It appears almost all the action is around the center diamond. Consider making the oval and diamond the upper level and the long reverse loop with parallel tracks the lower level. This way none of the turnouts will be obscured and some nice industry and city buildings can be positioned around the sidings without being obscured by track and other viewblocks.

One other minor point, the rise to run numbers in an earlier post include some rounding which shortens the actual horizontal distance required. For example a 1% grade is .12" in 12", so a 4% grade is .48" in 12". A 4.8" rise requires a true 10' w/o any vertical easements. At 4% some Legacy engines and some AM engines will require a short vertical easement. I have them on my 2% grades for flawless operation.

Thanks AmFlyer, I will think about your idea of reversing the elevation, that could be interesting! That would have a long tunnel through the center of the layout in-accessible - could be a problem.

I addressed the approximation/heuristic for easy grade caclulation in a long post to Wayne, above.

Regards, Ken

Using the approximate grades X"/96" discussed above, for Woodland Scenics inclines of 2%, 3%, or 4%; you can work the problem backwards:

Say you need 6" of rise, and you have 17' of run. And you want 2' of 2% easement at either end:

If after consideration, you like the 3% grade, and MUST have 6" of rise in 17' or run, you can decide to reduce the length of the easements to hit your target. [This is STILL using the approximate ?/96" grades that Woodland Scenics uses for their inclines]

Your equation is 6" == X*1/4" (2%approx) + Y*3/8" (3%approx). [X is the feet of 2%, Y is the feet of 3%]

Ken, I look forward to your final configuration. You have packed a lot of action into 5'x9'.

For info, the minimum vertical clearance on my layout is 4.5". The rail head to rail head distance is 5.25". It runs everything with the possible exception of the OldTimer engine and the Gilbert reel car but I have not tested those, they may clear as well. The track is MTH flex on cork roadbed on plywood.

@AmFlyer posted:Ken, I look forward to your final configuration. You have packed a lot of action into 5'x9'.

For info, the minimum vertical clearance on my layout is 4.5". The rail head to rail head distance is 5.25". It runs everything with the possible exception of the OldTimer engine and the Gilbert reel car but I have not tested those, they may clear as well. The track is MTH flex on cork roadbed on plywood.

Thanks Tom, and thanks for the info and your help!

I suppose NMRA standards are based on scale equipment, rather than traditional equipment. To get a larger vertical clearance I would need to increase the grade, since I can't increase the run (much?). Re-shaping the outside loop/grade would only gain an inch or two, so this layout can't go much higher without steeper grades. Traditional O layouts would use 6% and more grades, not sure I want to go there.

So, the layout as planned is for S-gauge SCALE equipment, not traditional/Gilbert.

I wonder if I should redo the grade with 6% max to accommodate some traditional/Gilbert stuff?

That might work for traditional/Gilbert equipment!

I reworked the grade to get a bit more length, and put the first turnout at the top on the 2% easement grade. I was able to get the total run to 130+".

I put the grade % changes at the track section connections.

I have measured the thickness of S FasTrack, and its right at 1/2", leaving 4.25" of vertical clearance. Tom reports his layout has 4.5" minimum vertical clearance that clears most everything that he runs. So this is 1/4" less than Tom's standard - maybe OK.

The thickness of the bridge beneath the track can perhaps zero - FasTrack is strong and rigid, and the bridge sides can be at the bottom of the roadbed, glued to it. The long part of the bridge is a 30" section - a couple additional piers can maybe support the weight without sagging. If contrived this way, then the vertical clearance can be 4.25", close to Tom's 4.5".

I suppose its possible to shave off 1/8" from the bottom of the plastic roadbed, to gain a vertical clearance of 4 3/8". Not too hard to do.

For continuous running, I would probably run one train reverse-loop to reverse-loop. The second train would stand on the passing siding, extending back into the mine spur.

The layout needs staging tracks, placed here under the elevated passing siding. The hidden turnout is accessed from the siding side, which is open.

Looks like it would be worthwhile to support 2-train operation, to connect the staging track to make a hidden passing track. Both turnouts are easily accessible from the open passing track side. Cool!

Ken, the tallest item on my layout is the oversize S gauge Big Boy. it needs 3.5" clearance. All the other equipment running on my layout will fit under a 3.25" clearance. The 4.5" clearance I have was set because we could, not that it was absolutely necessary. It also looks good at the tunnel portals etc. There are a few (hidden) places we had space issues. The track above the lower track crosses with the flex ties sitting directly on 1/8" aluminum plate to save space. I recommend avoiding steeper grades if you can.

I like the staging tracks.

@AmFlyer posted:Ken, the tallest item on my layout is the oversize S gauge Big Boy. it needs 3.5" clearance. All the other equipment running on my layout will fit under a 3.25" clearance. The 4.5" clearance I have was set because we could, not that it was absolutely necessary. It also looks good at the tunnel portals etc. There are a few (hidden) places we had space issues. The track above the lower track crosses with the flex ties sitting directly on 1/8" aluminum plate to save space. I recommend avoiding steeper grades if you can.

I like the staging tracks.

Thanks Tom!

If the entire 130" of 4% grade plus 2% easements were at 3% with no easements, the vertical rise would be 4". [X/96 grade approximation that Woodland Scenics uses.] An option.

With 15 S20 turnouts, I am glad that S FasTrack is considerably less expensive than O FasTrack. I ordered a command control R20 for about $60, correction: $82.95, where as a command control O-FasTrack is around $100.

Wow, that is quite a discount. The Lionel MSRP for a 20"R command control turnout is $109.99.

@AmFlyer posted:Wow, that is quite a discount. The Lionel MSRP for a 20"R command control turnout is $109.99.

Correction: Checked my invoice this morning. The turnout price came in at $82.95.

Very nice work Ken as always

Thank you Doug!

I suppose we can take the hidden staging/passing siding idea further, and do something like this: Its all close to the edge so easily reachable. This argues for the higher elevation at 4.75", with 2% easements and 4% main grade for ease in reaching and seeing the hidden tracks beneath. This certainly makes two-train operation easier.

The single-track grade can be protected by block signals at the top and bottom. I like that look, one of my favorite train experiences is camping at the end of a long siding in the mountains, where a train had to stop on the siding and wait for an opposing train to pass. The fireman got out of the cab and did a visual inspection of the passing train(s). The oncoming train was coming downhill behind a ridge, so we could hear the train, but not see it, but at night we saw the headlights playing against the ridge across the tracks long before.

Between trains, we were entertained at night by three deer running across the tracks and across a babbling brook, being pursued by two coyotes, with more coyotes calling in the distance. No idea how that turned out, probably not good for the deer. It was a full moon with a clear sky, and the scene was well lit.

Space for a loco storage track in the hidden trackage:

I swapped the elevated mine over to the other side turnout, so that the right side elevated turnout and spur can be used to hold or stage a train that is longer than the passing track, with the loco pointed down the grade and the train backed into and extending down the spur.

When the second train climbs the loop and takes the turnouts over the bridge and around the curve; as it clears the easement turnout, the waiting train can then proceed.

The right side spur can be built without the lighted bumper, and considered a connection to another RR, generating cars and trains. The spur could be used as a interchange track.

Next, added a second tunnel, place-names, and the rotating beacon:

Working on a version of this same track plan in O using FasTrack, with minimum curvature of O36. Uses much O48 and O60 turnouts.

The grade is a constant 4%, reaching an elevation of 5.5".

The tracks are close to the edge of the 5x9 surface, 1/4" at the left and right, and 1/8" at the top and bottom. I show a frame/fascia of 1x4 or 1x3 in brown.

There isn't enough space to close a figure-8 in the lower loop, due to the 1-3/8" roadbed-trimmed sections needed with the O60 turnouts.

With the two turnouts at the start and top of the grade at 2%, using the convenient Woodland Scenics inclines:

Total rise with these grade easements = about 5" (4.94"). I feel more comfortable with the turnouts on 2% grade, and the grade easements are good for operation.

When building the layout, you do not have to worry about these precise fractions, you simply use the inclines under the tracks, and cut them to fit each section length. Easy!

The grade up to the elevated loop is single track. A train can easily pass another on the lower O36 loop on the long hidden passing/staging track.

At the elevated tracks, the passing track here is short, more like a run-around track for switching. However, if the mine is located on the left spur, then the passing track and the spur running right can hold a waiting train, which backs down the spur to clear the turnout. When the second train climbs the loop and takes the turnouts over the bridge and around the curve; as it clears the easement turnout, the waiting train can then proceed.

The length of a train that can stand and clear the easement turnout is 76+". So that is about the limit of train length for two-train operation, at least one train needs to be this length, the second train can be a couple feet longer and still be able to pass at the top elevated, and at the bottom. The Lionel catalog states that their C&O Lionchief train set is 54" long.

The right side elevated spur can be built without the lighted bumper, and considered a connection to another RR, generating cars and trains. The spur could be used as an interchange track.

The layout can be wired conventionally with blocks and toggle-switches, but with two trains running, the frequency of toggle-switching and turnout switching would be a challenge - fun at first, but then would get old. So I recommend LionChief or TMCC/Legacy or DCS command control for this layout.

I am tempted to recommend command-control turnouts, to be controlled by a TMCC/Legacy hand-held controller. Running LionChief trains with the universal remote, then one operator has two controllers to fumble with. Perhaps a row of Fastrack turnout switches would be more convenient, with the universal remote in hand. Certainly much more work and hassle running wires to the many turnouts, to build it this way, compared to command-controlled turnouts. Perhaps a bank of six turnout switches for the visible O36 loop, a bank of five switches for the visible elevated trackage, and then a bank of four switches for the hidden passing-track&staging (including the turnout on the 2% easement beginning the grade).

Nice plan.

I fiddled with it before realizing it was S gauge, so glad to see it in O.

@GVDobler posted:Nice plan.

I fiddled with it before realizing it was S gauge, so glad to see it in O.

If you want to fiddle some more, here is the track plan in AnyRail. -Ken

I was curious to see what it would look like with an outside loop of O48 on the level center area. The grade is all O60 at 4% (4/96).

The dimensions are 6' x 9'8".

I look at it and wonder if it would be better and prettier at 6'x10'.

Revised as a 6'x10': staging tracks are longer, and the grade is actual 4% (4/100):

The 4% grade is O60, and the elevated is O48. So an O42 loco can run the outer loop and up the grade to the elevated. But only one return loop for reversing, the other is in the O36. Another variation might delete the O36 inner loop and make a reverse loop out of the O48.

Thanks Ken

My trial version of Anyrail6 won't open the file but I saved it anyway. Scarm trial allows more pieces to be in play, so I've been working to recreate it in that program.

Can you post a rendering view?

@Ken-Oscale posted:

Uhm, doesn't the reverse loop need to be facing the other way? As-is you'd have to back into it

@BurkusCircus52 posted:Uhm, doesn't the reverse loop need to be facing the other way? As-is you'd have to back into it

Right you are, thanks! Corrected:

@GVDobler posted:Thanks Ken

My trial version of Anyrail6 won't open the file but I saved it anyway. Scarm trial allows more pieces to be in play, so I've been working to recreate it in that program.

Can you post a rendering view?

AnyRail just sent out an update to registered users, and I created this most recent with that update. So the older versions will not open the most recent. There is no provision to save a file with the older version number.

What do you mean by a "rendering view"? I can give you a 3D image, but that does not have the data usually associated with a rendering view. Is there some part of the layout that is not clear enough to rebuild in SCARM, and generate a 3D image from that?

NOTE: We have had this discussion here on the forum before: SCARM uses the dimensions for track sections as published by Lionel, while the AnyRail publisher actually measured the track sections manufactured in China. I had a discussion with the AnyRail publisher about this, and it is on record on that forum. There are small differences, as I recall, almost 1/32". That seems like a small amount, but over multiple track sections, it can add up, to yield a difference of an 1/8" or more. These layouts have many small sections (unfortunately). So sometimes a SCARM layout will need to be modified in order to close in the software (but not in reality).

FasTrack, with its ridged integrated roadbed, is less forgiving than track systems with joiners or track pins. Those systems have much more flexibility (certainly with flextrack) in making good enough joints, and by making custom-cut sections. FasTrack can be stretched a bit, but it does not like it. But it absolutely CANNOT be compressed. So when I am working with FasTrack, I am careful to use very small tolerances, and to always have variances be in stretching by small amounts, and never compressing.

The S gauge FasTrack (which I like) uses conventional rail joiners, encased in a ridged plastic frame to keep the joiners from expanding with use over time [An idea pioneered by Kato 30 years ago with their N Unitrack and Unijoiners]. But, the roadbed grips together more strongly than the O gauge. Compression is never possible, and stretching is very difficult. The plastic coupling might need to be modified to even allow a stretch of 1/16". The molding seems newer and crisper.

Here are some pics of my shipment of S FasTrack that just arrived:

Looking at the pic of the joint between two sections, you can see how perfect the connection is, both in the road bed and in the rail. Tight tolerances!

The thickness of S FasTrack is right at 1/2".

Thanks Ken

I guess 3D is what I meant. Your explanation of the track gaps in the software was helpful. I often see a gap when making simple loops with the same track on both sides I figured it was the software. I use Scarm, but probably similar errors.

I'm trying to stay 9' x 5-6' with the 9' side absolute. So the 036 and 048 fastrack seems to work out fine. Although I'm thinking Gargraves track and Ross switches.

Always enjoy your work. Thanks

Thanks GVDobler, I appreciate your comments and discussion!

Here added some stream work, culverts, a few trees, and bridge details:

For fun, re-purposing Lionel's Granite Run Quarry Set to handle ore between the elevated mine and the smelter.

I added two sets to work their way back and forth between the mine and smelter. They fit on the spurs, but could be run without the little caboose and water car, adding two cars to each set (there is an expansion set with four more ore cars.

Fun to run these back and forth, and pass each other either on the high passing track, or using the hidden passing track. Then run other trains in between runs of these two short trains.

The little side dump gondolas actually dump manually, so a loader could be contrived in the mine, and then actually load and then dump the cars.

I made an ore dump bin and an overhead crane, to lift ore from the bin into the smelter. A few more trees scattered about, and the classic rotating beacon on one of the high points:

The Cartersville area, in the NorthWest corner of Georgia in the Etowah Valley, in which I live, happens to be rich in mineral deposits: gold, silver, iron manganese, ocher, aluminum, barium, hermatite. Gold, silver, iron, manganese, and ocher have been mined in the past, with ocher, manganese, barium, and iron being mined now, in modest quantities, so far as I can tell.

There was Cooper's Alatoona iron ore furnace located in the area before and during the Civil War, with rail service on the Etowah RR (tiny 1.75 mile mine RR, with two 1 mile spurs up the mountains to two mines) connecting with the Western&Atlantic. The town of Etowah sprung up around the furnace, which was razed by Sherman's army during the war, and never rebuilt. The furnace still stands, and is a historic landmark that you can visit and tour, not that much to see now.

So borrowing placenames for the RR:

Similar, but different.

Its an artifact of the web server compression software that makes the S-Gauge tracks look more precise than the O-Gauge; not so in the original illustrations.

I had to rework the left-bottom run that will be the grade up, and cut-in the crossover on the bottom-left.

I received my first S-Gauge loco yesterday, a FlyerChief NKP Berkshire. I didn't want to wait for the Northern to be released, and I will need two locos eventually. Even with the lack of wire handrails, it looks pretty good.

A lot of cab overhang on the S40 curves. That is a looong tender. The coupling between tender and loco could be closer.

An Intermediate Phase-1 for the O-Gauge, is not as good, the cross-overs between loops run the same direction, as does the return loop(s), so a backing move must be done occasionally.

Proceeding with my build-out: I am happy with my loco so far, and pleased with S-FasTrack. The next track order that I just placed with Charles Ro, gets me this much of the layout:

Four command control turnouts, so I will wire in my Legacy to control the turnouts, and use the Flyerchief remote for the loco control.

A short video of my FlyerChief Berkshire on my tiny test track. It staggers briefly over the turnout at its slowest speed about 1/3 of the time. Otherwise flawless operation.

The loco has pickup on one side only on the lead truck, traction tires on both side rear drivers, and pickups on all 4 wheels on the trailing truck. So if the traction tires lift all but the lead two drivers above the rails, the worst case for power pickup on a single side, is the lead driver and two pickups on the trailing truck: 3 points of contact.

The slowest speed is good. Top speed is almost enough to leave the tracks on this S40/R20 loop. Sound quality and volume are both good. Smoke is excellent, though you don't see it on this vid.

Ordered one PSX-AR-AC auto-reverser from Tony's Train Exchange, to play and experiment with. Looks to be simple to use, two wires as input, two as output. Detects polarity (phase) of the AC and reverses.

Ken, I am surprised to hear there is a pickup problem with your Berkshire. Mine has run flawlessly as has my FlyerChief Northern.

When you get your PSX-AR-AC there is one more step I recommend before final installation. Locate terminal block J6 along the edge of the board, it is used to set the trip current value. The default value with no jumpers is 3.8A. I find this value too low for running S gauge trains. Connecting a jumper from terminals J6-1 to J6-2 and a second jumper from J6-3 to J6-4 raises the trip current setting to 8.9A, the highest available. The explanation of this is in a small box in the right hand margin of p9 in the instructions. Pretty much everything else in the manual applies only to the DCC version.

@AmFlyer posted:Ken, I am surprised to hear there is a pickup problem with your Berkshire. Mine has run flawlessly as has my FlyerChief Northern.

When you get your PSX-AR-AC there is one more step I recommend before final installation. Locate terminal block J6 along the edge of the board, it is used to set the trip current value. The default value with no jumpers is 3.8A. I find this value too low for running S gauge trains. Connecting a jumper from terminals J6-1 to J6-2 and a second jumper from J6-3 to J6-4 raises the trip current setting to 8.9A, the highest available. The explanation of this is in a small box in the right hand margin of p9 in the instructions. Pretty much everything else in the manual applies only to the DCC version.

Thanks Tom, I noticed your jumper in one of your pics, appreciate the suggestion, will do! -Ken

Pics of the FlyerChief Berk:

You can see the height of this loco: about 3 3/4" clearance from track base to clear the top. Looks like my planning will be good for this loco anyway.

The tape measure is right up against the edge of the roadbed. At S40/R20 the overhang looks to be just over 1/4" for this loco, extending beyond the roadbed. Parallel center rail spacing of 3-3/4" would be generous. The minimum I work with on O clearance for O36 and wider diameter is 4.25", but prefer 4.5", but up to 5" is OK for appearance.

Here is the gap between loco and tender, again on R20/S40 curves. Could be tighter by 1/4" easily, but I suspect Lionel went with the larger gap so you could get your fingers in there to help couple. I did not see any convenient drawbar mounting holes to close this gap, like I have done on my earlier O Lionchief steamers.

I took a close inspection of the loco, and with a flashlight, was able to see that the wheels of the leading truck were not turning as the loco moved. Not at all! They were just skidding around the layout.

So after lubricating, and trying to break them in a bit rotating by hand, I suspected that the pickup wiper might be pressing too hard on the axle - it even looked a bit cockeyed, almost bent. So with a tool, I gently worked it a bit. Not sure if it is making contact now, I did not test with a meter. But, the wheel and axle are now turning as the loco rolls.

And, the loco is no longer stalling on the turnout at its slowest speed. Not even occasionally!

I ran it for more than an hour without a problem - nice! At high speed, the loco and S FasTrack are much quieter than O FasTrack. Very quiet, maybe 15% of the O gauge sound at maximum speed. That is interesting, as the S roadbed is as tall as O, with an echo chamber inside. But the rails are solid, rather than hollow.

Anyway, I would not have expected it to be so quiet, that is a bonus. I did not think that I cared much about the O FasTrack sound, after many years of train running. But after running the S FasTrack, I appreciate the decrease in noise a lot.

I played with the LionChief app, setting the momentum, top speed, and whistle and bell pitch. That was fun! Its a sweet-running beast! I reduced the background chuffing volume, as the FasTrack noise is so much quieter. Nice effect, my wife doesn't hear the train running from across the house as with O gauge, just the whistle.

After a couple more hours of running the loco at all speeds - zero problems!

Great headlight! Good sounds, very smooth running, good smoke.

My 2nd order of S FasTrack arrived this morning, to build this intermediate layout for testing and evaluation:

Great you were able to find and fix the issue with the Berkshire. The S gauge plastic based track is for sure far quieter than the O gauge equivalent.

As I am coming to S gauge from the O gauge world, I was interested in the relative proportions of S to O. S at 1:64 is 1.333 times smaller than O at 1:48 (48*1.333==64).

Put another way, S-dimension*64 == real-dimension == O-dimension * 48. S-dimension* 64/48 (1.333) == O-dimension

S40/R20 curves are the equivalent of O53.33 (about O54). S54/R27 is the equivalent of O72.

The 5x9 S layout is the equivalent of 6'8" x 12' in O.

I noticed something interesting about the S FasTrack turnouts: they have a "gate" in the frog, that switches position as the points change. The flangeway is unusually wide in these turnouts, so no doubt, the addition of this gate enhances the reliable operation of these turnouts. I imagine that this was widely known, just new to me.

I have the four turnouts installed, and have been running my train through them (the Berk and one boxcar, everything I own for now😁). No problems, very smooth.

One of the four turnouts switches reluctantly, I have been trying to loosen it up by breaking it in, some improvement. Another of the turnouts does not switch at all, probably a loose connection - I have not yet diagnosed.

50% of my turnouts received have problems "out of the box" with remote operation, not so good. I have not yet connected them to Legacy and tested them under command control.

An observation about my batch of S FasTrack 10" straights. These pieces can't be connected to each other, or other sections! The pressure required to push the connections in is stronger than the plastic, which deforms. The railjoiner fishplates are aligned properly.

So I have taken to shaving a bit off the inside edges of the "receiving" holder, which fixes the problem. I will try filing-down the "bulb" of plastic that enters the receiver. It is shaped as a circle, but could be tear-drop shaped, to facilitate entering the receiver with a bit of a point, while not reducing the pressure holding the sections together.

Some of the S54/R27 curves are very difficult to connect, but not as bad as the 10" straights.

The 1-3/4" pieces are easy to connect, as is the one 4.5" section. The S40/R20 curves are OK, some joints are difficult.

Planning the next phase of my build-out. After I receive and test my reversing unit (in transit at this time), I will send in my third FasTrack order for these additional sections. Also dependent on resolving the issues with my turnouts responding to the turnout remote.

Observation: S FasTrack does NOT have the convenient electrical connection blades on the underside, which O FasTrack has, allowing any section to be a power drop. Too bad, that is a step backward, but not as easy to manufacture because the rails are solid, so understandable. I have one 10" power terminal section which is doing fine for now, no drop in voltage detected so far.

Because the rail joiner "fishplates" are braced and enclosed by plastic to help them keep their shape without spreading, it would be difficult to solder a feeder to rail joiners to serve as electrical connections.

Ken, I have some FasTrack in a set but never used it. I do have a lot of the SHS track which uses the same .138 rail. The SHS track has a tab that protrudes down under the track from each rail joiner. This allows connecting a power feed to each rail joiner if desired. I have a 5'x12' loop of SHS track on my office floor so I can operate some engines conventionally. It has just one feeder connection. If I run a Gilbert engine there is no doubt there is a voltage drop at the far end of the loop as the engine slows down. If I run Legacy engines in conventional mode there is absolutely no change in speed, same with a FlyerChief engine. The cruise control compensates for the one to two volt drop. Given you plan to use FlyerChief engines it is unlikely more than one track feed is needed.

Ken

Just curious if you tried anything like a dub of petroleum jelly to connect the S track? I am considering an S layout after reading this thread.

@GVDobler posted:Ken

Just curious if you tried anything like a dub of petroleum jelly to connect the S track? I am considering an S layout after reading this thread.

No, I haven't tried that, perhaps that would help.

My filing-down of the circular bulbs that project into the receiver, plus a bit of trimming of the receiver, seemed to work. I had to do every straight section, both ends, but got the process down to a science, maybe a minute with each one, so not too bad after all. I used the edge of a knife scraping it along the plastic, away from the knife edge. So not cutting into the plastic. It didn't take much material removal to make a difference: lots of tiny scrapings, but I cannot see much deformation of the perfect circle of the "male" connector.

I also found a couple sections of straights had some flashing at the end, which I had to trim off.

The turnouts do not have the O FasTrack non-derailing feature. The gate in the frog is a place where a short will occur, if running against the setting (I tried it, and got a nice spark, and the transformer rolled-back the current). I think I can work up a detection circuit and a relay to switch the turnout automatically, an idea for the future. So the turnout is switching the polarity of both the points and the gates and frog when throwing the turnout. The entire turnout is "live", and the train does not hesitate with no "dead" rail sections, a very nice feature: no soldering of jumper wires or extra relays needed for electrical conductivity across the turnout.

A couple of shots of my about 4'x7' setup so far.

Messy construction process. The train surface is a 4x8 2" foam sheet, covered with a grass mat. This is the 3rd layout this board has hosted, so its looking beat-up.

I like the look of the layout and locomotive, its a nice change from O. With this much running, its running perfect, these two turnouts work fine. The "extra room" provided by the smaller scale looks very nice to my eyes.

I am returning the other two command-controlled S FasTrack turnouts to Lionel for replacement.

So the build is on hold until those are replaced. Meanwhile, I can test out the Legacy command control of the turnouts.

I can't recommend S FasTrack for a newbie or a kid, definitely "some assembly required" for me, and a tolerance for frustration, and being adaptable, and have some level of experience with model trains. Three issues: the pilot truck on the loco, this batch of 10" straights, and the 50% failure of my turnouts. But the result is very satisfying and enjoyable to run and watch. The track and roadbed connections are all "perfect", no gaps. So in spite of the issues, I intend to go forward with my build-out.

@AmFlyer posted:Ken, I have some FasTrack in a set but never used it. I do have a lot of the SHS track which uses the same .138 rail. The SHS track has a tab that protrudes down under the track from each rail joiner. This allows connecting a power feed to each rail joiner if desired. I have a 5'x12' loop of SHS track on my office floor so I can operate some engines conventionally. It has just one feeder connection. If I run a Gilbert engine there is no doubt there is a voltage drop at the far end of the loop as the engine slows down. If I run Legacy engines in conventional mode there is absolutely no change in speed, same with a FlyerChief engine. The cruise control compensates for the one to two volt drop. Given you plan to use FlyerChief engines it is unlikely more than one track feed is needed.

Thanks Tom, I appreciate your experience! I will likely add three more terminal 10" straights.

I looked at the rail joiners again, there is some exposure of the bottom of the joiner from underneath, but not enough to solder and attach a wire reliably. The joiner doesn't want to pop out of the FasTrack, and looks like it would be hard to get back in. It looks like the joiner end actually bends down 90 degrees into a slot in the plastic track piece.

I see a lot of engineering and manufacturing complexity ($ and time) in making the track sections and turnouts: I appreciate Lionel "giving it a go", I respect the effort!

Ken

Another thing I noticed was the headlight on your engine shining on the wall when the lights were on.

I remember as a kid wishing my post war engines had such a bright light. LEDs are cool indeed.

@Brendan posted:

Good idea Brendan! I would be afraid I would melt the plastic, but maybe I could pull it off without cold solder joints.

I could also try a small screw through the plastic to contact the underside of the rail. Maybe.

Those pictures of the layout are interesting.

When I first became involved with US 3RO, I was completely bewildered by the scale/semi-scale/O27 thing. There’s nothing like it, over here, and S Gauge never really existed.

Having now had experience of a “back of a door” O27 layout (6’6” x 3’0”) and comparing it to the pictures, and past experience of layouts of that sort in OO I can see how O27 developed, and why it maintained its lead over S Gauge.

@Ken-Oscale posted:I could also try a small screw through the plastic to contact the underside of the rail. Maybe.

I tried that at first but the plastic isn't thick enough. That is why I added the stryrene. even then, it wasn't really good. Maybe you'd have better luck. Maybe build it up with a blob of epoxy; that might have the holding power.

Brendan

Continuing my build: I connected my Legacy and Cab1L up, and tried the remote switching of the turnouts. Some success, one of the turnouts I thought would be reliable is now hesitating when switching from straight to curved. Sometimes I have to press the command button twice or three times, sometimes I have to move it by hand, and then it will switch OK a few times before getting "stuck".

[With all the problems with S FasTrack, one might almost think Lionel is trying to discourage folks adopting. I went with S FasTrack because of the ability to run the turnouts in command mode.]

So I guess I will have to open this one up, to see if there is something binding in the mechanism. I noticed that the turnout throwbar is slanted/cockeyed in between the ties, making contact at the switch stand end. I may be able to trim some from the throwbar, if that is the issue.

When it works, it is great, to be able to switch my turnouts without the remote controllers and running wires to each turnout.

The full build, uses 16 turnouts. At $83 each (not including shipping, etc), that comes to $1,328. A significant investment. But the turnouts just have to work, and they don't.

Not sure where that leaves me on this project. Right now, I have an oval with a passing track in 4'x7'. I really don't want to quit on this, I am stubborn.

On a Positive Note: after a couple more hours running the loco, still zero problems, perfect.

My switches are R27. I have 6 of them all purchased when they were first released. All went back to Lionel for repair in the first year. Problem was dead rails. I also have had problems with some switches not responding with one push of the Cab2 button. Makes it impossible to use the Route feature if it involved switches. When one of the switches came back from repair and would no longer respond to Command Control I gave up using switches in Command mode. I think there are some real manufacturing problems with the R27 switches.

@JFC454 posted:My switches are R27. I have 6 of them all purchased when they were first released. All went back to Lionel for repair in the first year. Problem was dead rails. I also have had problems with some switches not responding with one push of the Cab2 button. Makes it impossible to use the Route feature if it involved switches. When one of the switches came back from repair and would no longer respond to Command Control I gave up using switches in Command mode. I think there are some real manufacturing problems with the R27 switches.

Thanks for sharing your experience. Not good news, but I appreciate it. -Ken

I hate to pile on, but I have had the same experience with the turnouts. I only had two R27 ones. One of them just gave up the ghost, the other had the same or similar issue yours had with the throw bar. It would wedge against the side and not complete the throw. Not sure how it got that way; nothing appeared to be broken. My two R20 are fine. I have a mix of SHS and Fastrack. I am now in the process of collecting Fox Valley track for my next venture. Might use DZ2500s to throw them or servos/controllers connected to a SC-2.

Brendan

Some good news: after some more break in time, my troublesome turnout (of the two remaining out of four) is now working much more reliably. I put both turnouts in routes using TMCC/Legacy. While letting the loco run, I counted the successful operation of these two routes:

So, with this level of success, I am encouraged, and willing to take one more small step forward, by ordering two additional turnouts, while I wait for Lionel on replacing the two failures. Order placed, hope for the best!

Lionel's reply on my request for a RA:

We do not provide outright exchanges, but we can bring your switches in for repair. To do so, we will need the product/SKU numbers, a receipt showing the date and location of purchase, your daytime phone number, and the best address to ship the repaired items back to you via FedEx with a required signature. At this time, repairs are being brought in in batches due to our closure from March-June due to COVID-19. If you are looking for an outright exchange, you would need to contact the dealer from where they were purchased.

Fair enough, I will try a scan of my receipt and etc. Adds to the delay in getting these fixed, so I am glad I ordered two more, so I can make some progress.

The polarity detection and reverse unit should be showing up soon. I will report results when that comes in. I will need two of these for the full build.

Thinking about the turnouts in the "hidden" trackage. Although easily reachable from the back/top, when operating the turnouts from the front of the layout, because of the reliability question, the operator needs to be able to see the turnout to confirm the actual position: either the points or the illuminated switch-stand.

For one turnout, the operator may be able to see the position of the switch-stand in the dark tunnel by looking through the portal.

The other two turnouts need some kind of indication of position: I will have to think about that. How to detect that actual position of the turnout points and gate, that might be difficult. I suppose I could install a camera and have a screen to see inside. I would probably need to be able to see the hidden trackage anyway, for moving trains and cars.

@Ken-Oscale posted:Thinking about the turnouts in the "hidden" trackage. Although easily reachable from the back/top, when operating the turnouts from the front of the layout, because of the reliability question, the operator needs to be able to see the turnout to confirm the actual position: either the points or the illuminated switch-stand.

For one turnout, the operator may be able to see the position of the switch-stand in the dark tunnel by looking through the portal.

The other two turnouts need some kind of indication of position: I will have to think about that. How to detect that actual position of the turnout points and gate, that might be difficult. I suppose I could install a camera and have a screen to see inside. I would probably need to be able to see the hidden trackage anyway, for moving trains and cars.

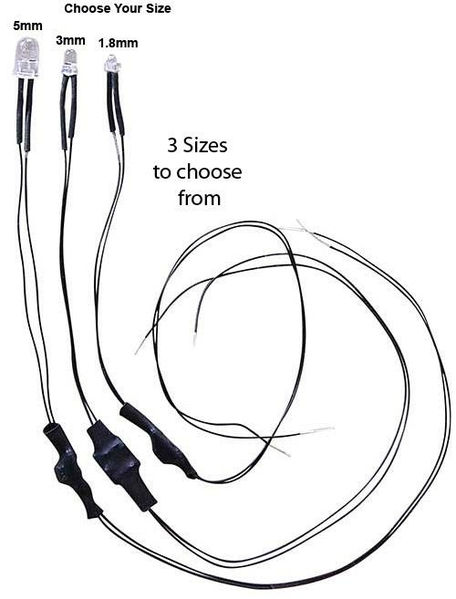

I wonder if the setting of the gate could be detected electronically, it will either have the polarity of the outside rail, or inside rail (however you want to label them). Maybe connect a diode to the gate to yield a pulsed DC current, through a capacitor to smooth the current, and then to a transistor, that enables a LED.  When the frog points to the diverging route, it is opposite polarity (black) from the rail (red), so current flows through the LED. LED with diode and resistor to drop voltage to LED. I have used Evans Designs LEDs in various colors "conditioned" so that you can connect them across an 18v AC power source, $3.25. Evans Designs Universal 7-19v LEDs

When the frog points to the diverging route, it is opposite polarity (black) from the rail (red), so current flows through the LED. LED with diode and resistor to drop voltage to LED. I have used Evans Designs LEDs in various colors "conditioned" so that you can connect them across an 18v AC power source, $3.25. Evans Designs Universal 7-19v LEDs

Perhaps instead, I could overlay a small DC voltage across the gate and frog just for detection purposes, and compare it to either of the rails to complete a circuit, and power a LED. Its either the same as the rail (no voltage differential, or opposite with voltage and current flow). I will have to look in the forum, this sort of thing has already been done.

Or just complete a DC circuit to light an LED:

Ken, I will start by saying I do not have any of these turnouts and know little to nothing about their design. That said, is the failure of the points to throw a mechanical binding or a signal issue? Do the points move all the way to the closure rail or do they stop part way? The mechanical issues are repairable, there are some post on this on the 3 rail side, they may or may not not be applicable to S gauge.

If it is a signal issue then that should be an easy fix. I think the turnouts are using the Legacy signal off the rail connected to the Legacy base. If so I recommend a few .1microfarad 50V ceramic capacitors be used to put the Legacy signal on both rails. Then next the return through earth ground propagation can be improved. Connect a wire, any gauge, to the ground pin on the Legacy base power supply. Route that wire just beside or under the turnouts. That should fix any signal issues. The same fix applies if anywhere on the layout an engine loses the Legacy signal, that is indicated by a flickering headlight. I am pretty sure this is how the command turnouts are controlled. All of mine are hardwired from ASC2's so I do not have any signal reception issues but that is a more involved and expensive setup.

@AmFlyer posted:Ken, I will start by saying I do not have any of these turnouts and know little to nothing about their design. That said, is the failure of the points to throw a mechanical binding or a signal issue? Do the points move all the way to the closure rail or do they stop part way? The mechanical issues are repairable, there are some post on this on the 3 rail side, they may or may not not be applicable to S gauge.

If it is a signal issue then that should be an easy fix. I think the turnouts are using the Legacy signal off the rail connected to the Legacy base. If so I recommend a few .1microfarad 50V ceramic capacitors be used to put the Legacy signal on both rails. Then next the return through earth ground propagation can be improved. Connect a wire, any gauge, to the ground pin on the Legacy base power supply. Route that wire just beside or under the turnouts. That should fix any signal issues. The same fix applies if anywhere on the layout an engine loses the Legacy signal, that is indicated by a flickering headlight. I am pretty sure this is how the command turnouts are controlled. All of mine are hardwired from ASC2's so I do not have any signal reception issues but that is a more involved and expensive setup.

I don't think a signal issue, the points try to move and the turnout "buzzes", so I believe its a mechanical issue, probably the throwbar that is angled and scrapes.

Ok, that sounds like some difficult detail work to correct the problem on top of having to disassemble the turnout.

@Ken-Oscale posted:I wonder if the setting of the gate could be detected electronically, it will either have the polarity of the outside rail, or inside rail (however you want to label them). Maybe connect a diode to the gate to yield a pulsed DC current, through a capacitor to smooth the current, and then to a transistor, that enables a LED.

When the frog points to the diverging route, it is opposite polarity (black) from the rail (red), so current flows through the LED. LED with diode and resistor to drop voltage to LED. I have used Evans Designs LEDs in various colors "conditioned" so that you can connect them across an 18v AC power source, $3.25. Evans Designs Universal 7-19v LEDs

Perhaps instead, I could overlay a small DC voltage across the gate and frog just for detection purposes, and compare it to either of the rails to complete a circuit, and power a LED. Its either the same as the rail (no voltage differential, or opposite with voltage and current flow). I will have to look in the forum, this sort of thing has already been done.

Or just complete a DC circuit to light an LED:

It can but the frog polarity switches before the throw completes. It is not reliable as a throw indicator. Some mechanical method like a microswitch or a reed/optical sensor connected to the throw would be probably be more accurate.

Brendan

@Brendan posted:It can but the frog polarity switches before the throw completes. It is not reliable as a throw indicator. Some mechanical method like a microswitch or a reed/optical sensor connected to the throw would be probably be more accurate.

Brendan

Thanks, good to know. I would have through the electrical connections are in line with the solenoid that moves the points, so they all make/break together.

I decided to extend my build, from a 5x9 to a 5x10. I have the space and like the look - that is, the expansiveness of the smaller trains in the same space. HO is just too small, but S still has some of the physical presence of O. So I am going for this Phase 1 intermediate version.

The autoreverse unit came in yesterday. Its bigger than I expected, with big heat radiation fins. Will experiment with over the weekend.

A couple pics of my evolving 5x10 layout (currently 4x10): The 5x10 in S is comparable to a 6'8" x 13'4" in O.

Latest Two S FasTrack R20 command turnouts: The latest two turnouts work very well, no problems or hesitation on switching. No problems with remote or command control.

These two both had two difficult-to-connect problems:

Here is a pic of the auto reverse unit. Larger than expected, with large heat radiators. I will work on testing it this weekend. Reading the manual, this is a very impressive piece of electronics, with many capabilities and much flexibility, more than I will use - a very well thought-out design.

A nice view of the train.

Experiment for more interest in the grade, to break-up the many parallel lines. Not sure if I like it or not. Its all R27 (==O72) to reduce the added drag on a train climbing the grade with curves (except one R20 (==O54) near the top, the turnouts are R20).

I hope there is enough commercial interest that Lionel invests more in this track system. 1/4-section of S27 would be great in making graceful curves. And add a #4 command switch (LH&RH). And R24 (S48) curves would be great as well. And fix some of the production problems I am encountering.

Ken, I have five of those PSX-AR-AC's. The heat sink is needed because these are rated at 10A continuous. I recommend not devoting too many brain cells to that manual. 90+% of the features described are not included in the AC version. Obviously any feature or setting that uses a CV value is not included.

I think we can forget about numbered S gauge turnouts from Lionel. As a minimum numbered turnouts would need custom curve segments to allow "closing a circle" with sectional track.

SHS made 19", 24" 29" radius curves. These work well with the 5" curve spacing, no engines or cars hit on curves. Lionel has 19" and 27" so they would need to make a 23" to have 4" spacing on the curves. I agree Lionel needs to ship customers turnouts that work first time, every time.

If you want to eliminate the appearance of parallel track, maybe rotate the entire lower level oval and "X" crossing 15 degrees clockwise on the layout. 22.5 degrees would be better but I do not think there is enough room to do that.

@AmFlyer posted:Ken, I have five of those PSX-AR-AC's. The heat sink is needed because these are rated at 10A continuous. I recommend not devoting too many brain cells to that manual. 90+% of the features described are not included in the AC version. Obviously any feature or setting that uses a CV value is not included.

I think we can forget about numbered S gauge turnouts from Lionel. As a minimum numbered turnouts would need custom curve segments to allow "closing a circle" with sectional track.

SHS made 19", 24" 29" radius curves. These work well with the 5" curve spacing, no engines or cars hit on curves. Lionel has 19" and 27" so they would need to make a 23" to have 4" spacing on the curves. I agree Lionel needs to ship customers turnouts that work first time, every time.

If you want to eliminate the appearance of parallel track, maybe rotate the entire lower level oval and "X" crossing 15 degrees clockwise on the layout. 22.5 degrees would be better but I do not think there is enough room to do that.

Lionel and other manufactures package turnouts with small sections: Lionel O FasTrack O36 with an O36 1/4 section. Lionel O FasTrack O60 and O72 turnouts with 1-3/8" sections with roadbed trimmed, just for use with turnouts. I think the low volume of sales is what discourages Lionel from attempting this, in S or O - doesn't justify the development and tooling costs.

As you observe, there is not enough space to rotate the entire layout, without making major changes. So, I am looking at what is feasible with this plan.

I am finding that the S FasTrack 30" straights can only be ordered in a bundle of 10. So I ordered 10 yesterday. Particularly with the extended layout to 4x10, I need more straight lengths than previously, and will replace 10" straights in groups of 3, to be reused in different areas.

Two activities to do now: test the PSX-AR-AC, and purchase and cut a 2" 4x8 sheet of foam, to add 1' of width to make the 5x10.

Train and turnouts continue to run well, with no issues.

I tested the turnout indication LED idea: Works fine, very easy with the "conditioned" LEDs from Evan's Design for up to 19v AC. I wired one green and one red LED from the frog to an outside rail and tested.

Unfortunately, the make/break of the internal turnout wiring to the frog/gate and points does not have a dead spot in the movement. Turning the turnout stand manually, the electrical connection (and my indicators) go from one setting to the other, even when the points and gate are not fully one side or the other. That is to say, the LEDs indicate the direction correctly when the turnout is correctly switched, but will show incorrectly when the turnout is "stuck" midway through: a "false positive" situation. So the LEDs will correctly show the position of the turnout when completely thrown, but will not show a stuck turnout. (no turnouts are sticking at present). Too bad.

I will still use the LEDs to bring out the setting of the hidden turnouts, showing in a block signal at the tunnel entrance, so I can see how the turnouts are set without being able to see the hidden turnouts. That much works fine.

I will remove the turnout remote controllers soon, no longer needed with command control.

@Ken-Oscale posted:I tested the turnout indication LED idea: Works fine, very easy with the "conditioned" LEDs from Evan's Design for up to 19v AC. I wired one green and one red LED from the frog to an outside rail and tested.

Unfortunately, the make/break of the internal turnout wiring to the frog/gate and points does not have a dead spot in the movement. Turning the turnout stand manually, the electrical connection (and my indicators) go from one setting to the other, even when the points and gate are not fully one side or the other. That is to say, the LEDs indicate the direction correctly when the turnout is correctly switched, but will show incorrectly when the turnout is "stuck" midway through: a "false positive" situation. So the LEDs will correctly show the position of the turnout when completely thrown, but will not show a stuck turnout. (no turnouts are sticking at present). Too bad.

I will still use the LEDs to bring out the setting of the hidden turnouts, showing in a block signal at the tunnel entrance, so I can see how the turnouts are set without being able to see the hidden turnouts. That much works fine.

I will remove the turnout remote controllers soon, no longer needed with command control.

That's what I was getting at in my previous comment. If you want positive indication, you'll have to devise something mechanical.

Brendan

Experimenting with the Legacy controller to switch command routes. It would seem from my experiments, that more turnouts in a route increased the probability that a turnout will not switch. This maybe implies a voltage drop issue with say four switch machines all trying to switch at the same time. I may do some experiments with this idea. Currently, I am powering the layout with two CW-80s ganged together, putting out maximum voltage, with the engine running while I hit the route. The turnouts take power from the track.

I also notice that if the route button is held down, the controller will send a command repeatedly in successive pulses. I have even seen a route behave this way, with the button held the entire time: pulse-1: switch one fires, the others buzz. Pulse-2, another switch fires, the others buzz, etc until all four turnouts have switched, and the button is released.

Sending a command to an individual turnout: they are all switching reliably as individuals.

The open circuit voltage output of the CW-80 is 17.9v.

You might try increasing the switch delay in the "Route Throw Rate" on the Cab2. I seem to remember that things worked better when there was a substantial delay. Then one push of the button would sequentially throw the switches with a delay between each of them.

@JFC454 posted:You might try increasing the switch delay in the "Route Throw Rate" on the Cab2. I seem to remember that things worked better when there was a substantial delay. Then one push of the button would sequentially throw the switches with a delay between each of them.

That sounds like a great idea! Unfortunately, I have the Cab1L, I think that feature is only available on Cab2.

My Berkshire threw a shoe! I lost a traction tire after less than two weeks of operation. It deteriorated and left black bits on the drivers and rails, and stretched out. I was able to clean the loco up, and re-seat the traction tire, but it came off again while running. So I cut it off, and will replace it eventually. For now it is running fine with just one traction tire.

I added a highway underpass on the right side of the S 5x10 layout.

It can't be seen from the drone view, but the underpass and trestle reveal the "hidden" route around the outside, which lines up almost exactly with the overhead elevated return loop curve. The road has a grade crossing directly under the elevated line. A cool look, and its good to get a glimpse of the train running this route.

I have to say, I’m not getting the feeling that Lionel are fully committed to this.

I see what you are trying to achieve, but if I were approaching it I’d go for On30. Similar size to S, lots of choice for track and rolling stock, Bachman and AMS prices and reliability and if you WANT something a bit “special”, the rare Mountain Models 2-8-2 locos and San Juan Car Co rolling stock.

@Rockershovel posted:I have to say, I’m not getting the feeling that Lionel are fully committed to this.

I see what you are trying to achieve, but if I were approaching it I’d go for On30. Similar size to S, lots of choice for track and rolling stock, Bachman and AMS prices and reliability and if you WANT something a bit “special”, the rare Mountain Models 2-8-2 locos and San Juan Car Co rolling stock.

I did consider On30, I am a big fan on On30. A previous 6x12 O layout also had On30 climbing a mountain. My brother was a big 'N' modeler, and my work with On30 convinced him to try it, he is now building his 3rd On30 layout.

I thought about doing a version of the layout in On30, but I don't think there would be much different or anything new to learn from the effort. I have included On30 in layout designs here on the forum - no interest from forum readers. I had not worked with S before, it is new and a bit of a stretch.

There is much to like about 'S', just too many problems for me with S FasTrack. Still continuing the effort, perhaps things will go better as the build evolves.

@Ken-Oscale posted:I did consider On30, I am a big fan on On30. A previous 6x12 O layout also had On30 climbing a mountain. My brother was a big 'N' modeler, and my work with On30 convinced him to try it, he is now building his 3rd On30 layout.

I thought about doing a version of the layout in On30, but I don't think there would be much different or anything new to learn from the effort. I have included On30 in layout designs here on the forum - no interest from forum readers. I had not worked with S before, it is new and a bit of a stretch.

There is much to like about 'S', just too many problems for me with S FasTrack. Still continuing the effort, perhaps things will go better as the build evolves.

I take your point, but would venture to disagree. I’ve been involved with On30 for some years and it’s fascinating, although a bit “full-on” - I still haven’t really got to grips with working everything from DCC, for one thing.

But there’s so much choice in track and rolling stock - I’m particularly a fan of the Bachman 2-6-0 and outside frame 2-8-0 locos, for one thing. Cheap, easily available and very robust. The BIL C-16 is a real cracker, too, if you can find one.

@Rockershovel posted:I take your point, but would venture to disagree. I’ve been involved with On30 for some years and it’s fascinating, although a bit “full-on” - I still haven’t really got to grips with working everything from DCC, for one thing.

But there’s so much choice in track and rolling stock - I’m particularly a fan of the Bachman 2-6-0 and outside frame 2-8-0 locos, for one thing. Cheap, easily available and very robust. The BIL C-16 is a real cracker, too, if you can find one.

No disagreement - to clarify, what I meant would not really be different is the layout diagram. An actual layout build would be dramatically different.

As I have extended my actual layout to 5x10 (well, 4x10 for the moment), I thought I could look at a redesign to use the extra length a bit differently, and add a yard inside the R20 loop. With different industry track arrangement.

This version becomes more dense with track, and less open, and less room for structures.

With more space comes more opportunity! I am wondering how all those short sidings will be used, it looks like some will be hard to reach. My experience with sidings and knuckle couplers has been mixed. One reason is there was a multi year run of AF by Lionel with couplers that did not open wide enough to function correctly. The original Gilbert are ok and the latest production runs from Lionel are better. If all you want to do is drop and pick up cars with an engine with electrocouplers, that works. If you want to break up a string of cars then each siding needs an uncoupler, more $$$ required.

If you keep expanding the layout you will become a great Lionel customer with all the FasTrack purchases.

@AmFlyer posted:With more space comes more opportunity! I am wondering how all those short sidings will be used, it looks like some will be hard to reach. My experience with sidings and knuckle couplers has been mixed. One reason is there was a multi year run of AF by Lionel with couplers that did not open wide enough to function correctly. The original Gilbert are ok and the latest production runs from Lionel are better. If all you want to do is drop and pick up cars with an engine with electrocouplers, that works. If you want to break up a string of cars then each siding needs an uncoupler, more $$$ required.

If you keep expanding the layout you will become a great Lionel customer with all the FasTrack purchases.

I have 360-degree access around all sides of this layout, on a rolling table in addition.

I received my 10 30" straight sections yesterday. As with O FasTrack, the roadbed is three 10" straights, with a continuous rail joining the sections. The "ball" of the joints on these is smaller than my 10" straights. You can actually see a gap between the ball and socket.

Hope to do some more work on the layout today. Loco is continuing to run perfectly, no change on the performance of the turnouts from previously reported (imperfect).

I have to purchase at least one more 2" 4x8 sheet of foam, in order to cut a 1x8 section to make my 4x8 a 5x8. I have a 2x4 extension from a previous layout build, but if I use this, I need an 1x2 piece to go with it.

So I think it would be better structurally (as the foam sheets are supported on 2x2s) to instead cut a new piece that is 5' long. I might just as well cut a 4'x5' piece, as shown in the illustration below, to yield a 5x12 layout. I previously had a 5x12 layout in this space, which is the max I can do in this layout space anyway (with 360-degree access).

I have just extended the previous design, I have not tried to do anything new with the extra length.

If I was to start from scratch and not reuse my beat-up 4x8, I would chop three 4x8s to 4x5s, and lay them side-by-side.

Access around the ends is tight, so I may trim the corners, or make them curved. This helps me move around the ends more than you might think.

Maybe delete an industry track for a steam loco service track:

On the other hand, maybe with the hidden storage, I don't need four yard tracks, and can add back an industry track.

I needed to create electrical gaps for the reverse loop and electronic reverser testing. I used a fine Zona saw to cut through both rails on two sections of R20 at the half-way point, creating a pretty fine gap in the rails. I had to hold the track up to the light to ensure the gaps went all the way through the web, they do.

On my first attempt to cut the rails, I cut about 1-1/4" from the end. Bad idea. The small plastic rail spike heads holding the rails to the roadbed did not have enough strength, and one of the short-section rails popped-out. It went back in, but does not seem strong enough. I set this section aside.

Consequently, I decided to strengthen my gap-ed track sections with some superglue. I purchased this LocTite superglue, which dries clear. It is actually more liquid than I would have liked, so my gluing is messier than I would have liked. Hopefully this will be less noticable when dry. I put glue on both sides of the rails, across the gap, and at three ties on either side of the gap. I used a disposable plastic fork to try to work the liquid glue into the small rail joint. We shall see if this is sufficient. I will file down any glued tie points that contact the flangs.

Here is my next incremental build phase:

Next steps:

This expanded intermediate layout version needs 10 of the 30" straights, exactly what I happened to have purchase in a bundle.

Relationship between S and O: S-dimension* 64/48 (1.333) == O-dimension

S40/R20 curves are the equivalent of O53.33 (about O54). S54/R27 is the equivalent of O72.

The 5x12 S layout is the equivalent of 6'8" x 16' in O.

I have not constructed an O layout that large (nor any smaller scale.) My largest previous O layout was 6x12. I did have a larger G gauge layout in the side yard 19 years ago, long ago taken down.

Tested the autoreverse board yesterday: works perfectly, install was ridiculously easy. No failures, no errors.

I did not need to fine-tune the detection circuit with a jumper wire. So far, so good.

There is a small spark when the loco bridges the gap between track sections. Not big enough to be of concern.