Explanation of Brick handling a short--it's cascade protection (involving a 2d breaker downstream)

Hi, guys--

First, this was a really good and useful discussion. PLCProf really came close toward the end (cutting the plug off, not using as intended). Unfortunately the real cause may turn out to be the on-off switch in the primary (OP's brick), which will cloud the real issue, which is a more common trouble, I think. Notice that one of the posters (different from OP) actually damaged his own 180w PH transformer by putting a solid short on it, on the load side (ie, layout side).

Well, right to it. With the special plug on the 18v output, you can only plug into certain devices. Perhaps the third (so-called "unused") pin in this plug ti arranged so that you cannot physically plug a 180w brick into a voltage regulating device that can handle only 7 amps (ie, that requires the 135w brick, etc).

These are things like the PowerMaster (PM) controllers, and the later ZW transformers electronically-varied output voltage. Some of the earlier such devices may have had paired triacs, or later, MOSFET transistors. What I noticed in one was that the triac or MOSFET (forgot which there, but think it was a MOSFET) was rated for 35 amps although used in a 7-amp circuit. It would be 50% duty cycle with the pair, so it could actually handle 70 amps for one cycle, if the heat-sinking was up to that. But it's more like how many cycles at 70 amp. There was a large aluminum fin attached; I guessed at its effectiveness. With a 77-amp max short current from a 135w brick, this looked adequate. Later, I found the same 35w chips used in a 10-amp utilization device, similar heat-sinking.

Typically the sensing was only across one chip. So the interrupt time could be up to nearly two cycles. At the same, I realized I had initially overlooked the 50% duty cycle also. BTW, "Typically" is an engineering term that means "the one I looked at."

The importance of this is that these devices (chips) burn up so fast that their own ability to interrupt current must be used to protect themselves. So we know that a likely speed of operation is 2-cycles at max short circuit output.

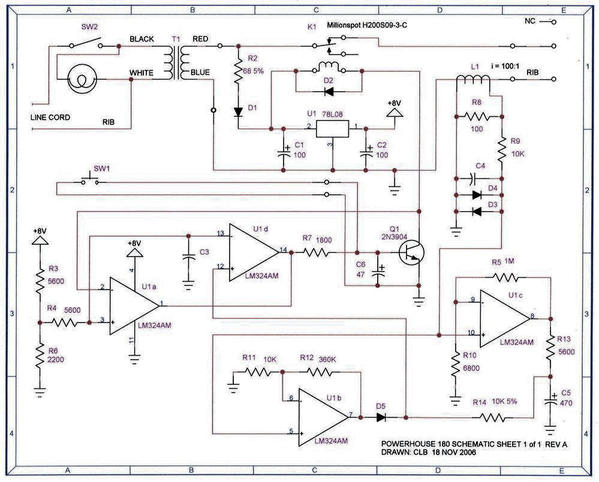

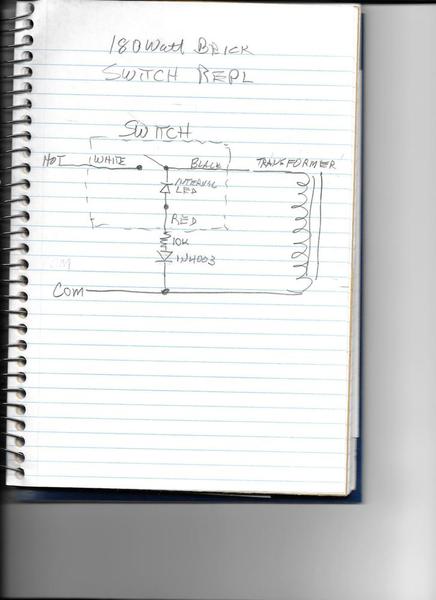

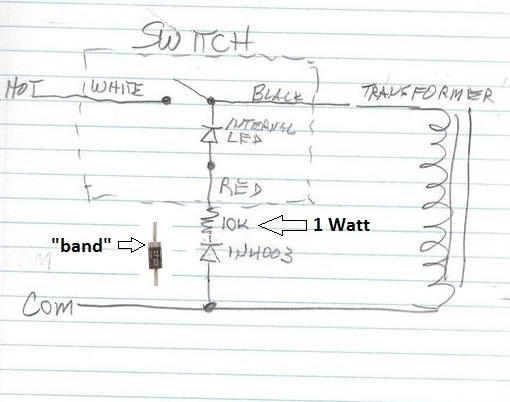

So, what is needed is to analyze Cam's circuit drawing, with a view of seeing how long the time delay to open the circuit is (the requirement is that any current over the amount necessary to output over 180w be interrupted in not over 60 seconds). I realized after a cursory look at the circuit that I actually once knew how to do this. What a shock. Someone here make this calculation, and save me the effort. The time delay will then only require that the relay carry the max short for two cycles, which should be easier than closing into such a short, and easier still than opening one. I suggest using 100 amps as the max short. Then the current transformer in the diagram produces 1/100 ampere, making calculation in one's head easier. The open triangles indicate connection to the 8-volt bus, including its supply.

UL 697, Toy Transformers, was changed immediately prior to the first brick (135w) to "not require a transformer to interrupt all the current it may produce..." contrary to the previous requirement, So, the Lionel brick is actually compliant, and not underprotected. It is actually a means of reducing the total cost to users. I've always recommended that MTH DCS users make their connections thru the line-side shed lock-on (the 10-amp version has binding posts inside on the output). Although this is a very large supervised relay, its moving contact is still not so large that it's operation, unless intentionally delayed, would be subcycle. BTW, cutting the plug off the brick voids its UL label.

--Frank