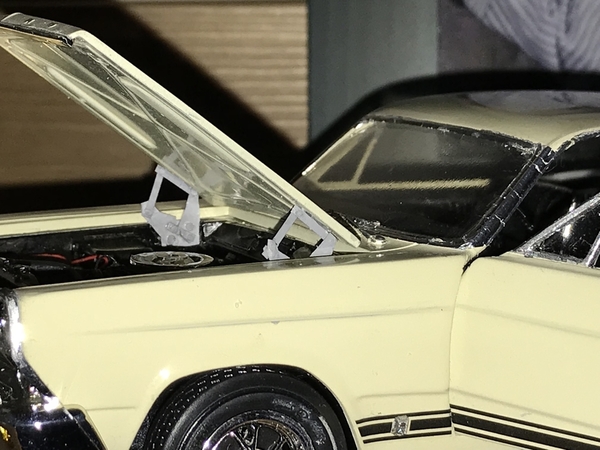

Thanks Mark! I added one more detail to the Ford before putting it on the shelf, a set of scratch-built semi-scale hood hinges. I found pictures of a set of 66 Fairlane hood hinges on eBay which I then used as a template to draw a detailed drawing on CorelDraw. I pasted multiple copies of the drawing onto some styrene and cut the parts out. I used some photo-etch brass free material for some of the smaller arms, and use 0.025" round styrene rod for pins. Because of all the plastic, the hinges are not robust enough to actually operate although they are mechanically correctly and do move properly, but they're flimsy, so I applied thin CA to the assembled hood to lock it into place.

All that's missing are the counter-balance springs. If I were to build another car model AND wanted to make these fancy hinges workable, I would make them entirely out of brass and add some springs (either real or simulated). There would be so much drag in the mechanism that it would hold up the hood regardless.

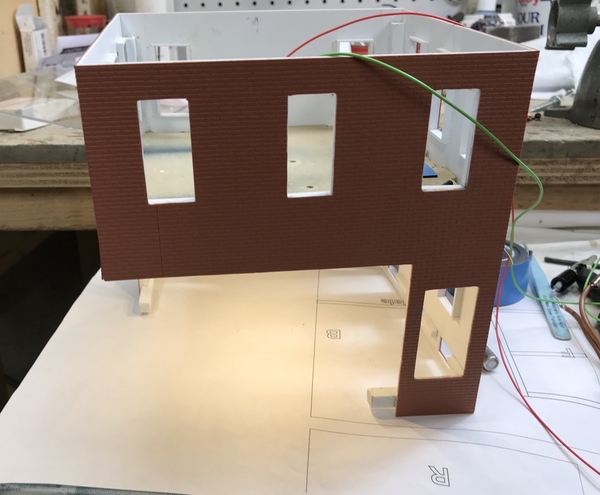

Now… onto Nighthawks. As promised I started back at work on it today. I got the second floor (first floor ceiling) fitted. I had to notch the heck out of it to clear the widen window boxes so it would settle down onto the floor supports. The second floor will not be decorated and will be blacked out, so the way the floor fits is immaterial. I did not attach the floor yet since there's a lot to do before that point.

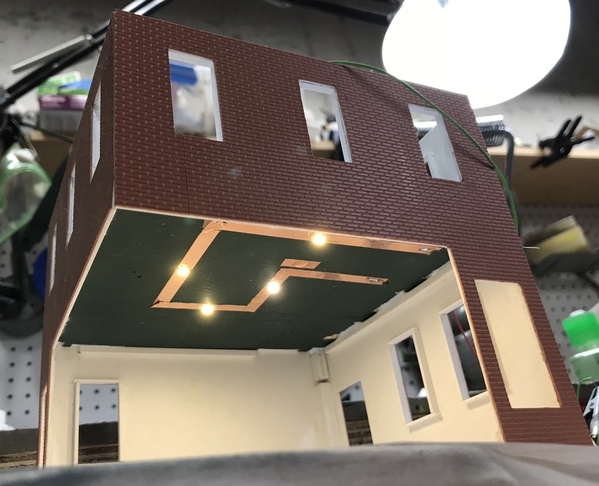

But, what I did do was get the lighting installed. I used the very small surface mount LEDs soldered to adhesive copper foil laid out in a series pattern. I found that these small LEDs, while very bright, are also very delicate and heating too long while soldering does seem to kill them. I test them when isolated and then again when soldered into the foil and then again as a circuit. I'm now using CL2N LED driver chips. These little marvels eliminate all the guess work about what to do to limit the current in the circuit. You put the plus voltage on one of the three leads and the minus on the other end (the middle lead doesn't connect to anything) and regardless of whether you put 5 VDC or 90 VDC all you get out is 20 milliamps, which is just what the LEDs love. The limiting factor is the voltage drop across each LED. Each drops about 3 volts, so in a series circuit, with 4 LEDS, that's a 12 volt drop and I'm driving it with a 12VDC power source so all's well. If I was using a 6 volt source, I would use two drivers in a parallel circuit with 2 LEDs in each leg so each leg would drop the 6 volts. Again, I no longer have to worry about current. So with a 90 VDC power supply I could drive 30 LEDs in series with just one LED driver chip. This is so much easier than calculating the resistor values needed in conventional LED systems.

Here's the lighting under test.

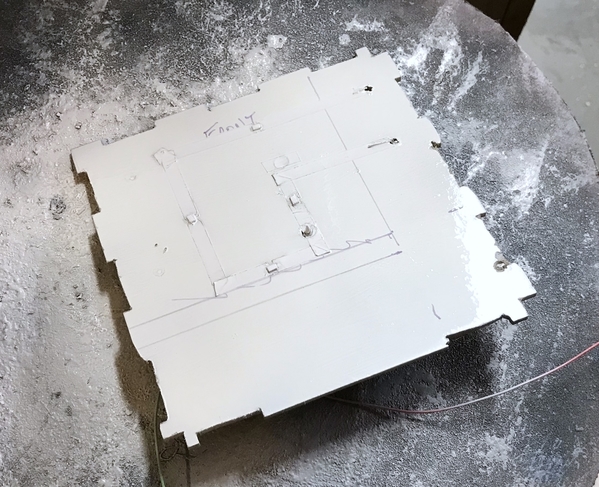

And here's the array. The positive and negative terminals are on the bottom of the LED. They're close together so you cut about a 1-2mm gap in the foil, tin the foil, hold the LED on the solder and then heat each side until the LED settles in, and then get off. Again… too much heat and you can kill the LED. They're only $0.29 each so losing one or two is not a big deal.

I form the copper tape corners so I don't have to solder them. This is a trick I learned in the 70s when I was installing old school burglar alarms with the led foil tape on the window glass. The foil had to be continuous so you bend it back on itself, turn it 90 degrees and keep going. From this view you can see the widened window boxes. I will put on "sheet rock" to make regular looking walls.

I then masked each LED with a small piece of tape, premiered, and painted the ceiling flat white.

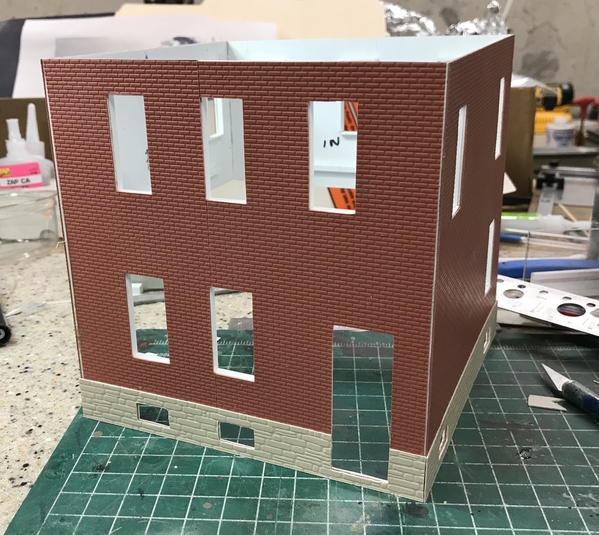

The last thing I did today was add the Plastruct stone wall appliqué to the bottom scale 3 feet of the building. This will be painted to simulate stone. I'm letting it dry over night and work on it tomorrow.

The Plastruct stone worked well in this application since it had nice smooth courses and makes a nice straight top edge which building foundations have. The windows mount from the inside to reveal some brick wall thickness. I'm using conventional Tichy windows turned upside down and mounted from the back which puts the upper sash on the outside and the lower on the inside as it should.

I realized today that the small, bottom, upside-down turret is nestled into the building so 3/4 of it is exposed. That means that the piece has to have a 90 degree notch cut into it, or I have to cope cut the buildings wall so the turret slips into it. I will probably be easier to cut the turret, but it has a ball bearing epoxied to the apex and an aluminum shaft that was used to hold it in the lathe chuck when I made it. I believe that an abrasive cutoff disk in the Dremel could handle the metal parts. We'll see.

I'm at a point where I have to pre-plan the assembly carefully. The interior probably has to be completely fit before the front window assembly goes in since it will hard to do it from the top down. It's also tricky just getting the floor plate into position without any walls or furnishing in place. I spend a lot of time just staring at what's built so far and building it in my mind to figure out the best approach. That's the one challenge with scratch-building that people don't speak about much…no instruction sheet. I also have to figure out the best time to paint the exterior since I can have the windows installed so painting should happen soon.