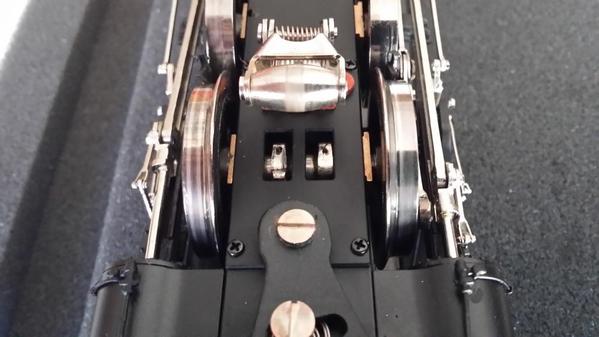

This is a brand new engine from Sunset 3rd Rail, AC9 articulated steam engine. I'm not bashing 3rd Rail here, and Scott Mann has been working with me from day one on this. I'm looking for some other opinions as to what may be the problem. I shot some video so you could hear it. It's dark, but you will be able to focus on the sound. The chuff cuts out, and it doesn't matter whether the switch is in 2 chuff or 4 chuff mode. This is the 2nd AC9 I've had with this same issue. At first, right out of the box they run fine and sound great. After about 30 minutes of run time, the chuff problem starts. The more I run it the worse it gets. Don't matter if I let it sit and cool down, and then run it again later. When I shot this video in the dark, it had been sitting all afternoon so it was cold. Scott sent me a new radio board and sound board. Upon installation, it sounded good, but the more it ran, the chuff started to cut out and continue to get worse.

So tell me what you think after you hear it run.