The longitudinal centering of the worm gear and the worm wheel was the main issue I believe. Basically, the worm ran out of thread and became a screw with all of a screw’s torque prevailing properties in a reverse stall scenario. Not something you want in what was intended to be a low friction drivetrain.

The motor and worm angle is ok. Word of warning, keep an eye on the gaffer’s tape used to secure the wires along the fireman’s side of the can motor shroud. Getting it wedged in the motor mount/gearbox cover can cause the gears to not mesh well. The motor angle isn’t so important, the gear mesh is set by the (perpendicular) centerline distance of the worm gear and wheel which is best set vertically in this setup.

Gear mesh seemed fine with the original factory shim. This is controlled vertically by the thickness of the gearbox cover.

Worm centering across the worm wheel laterally seemed fine. This is also controlled by the gearbox cover/motor mount.

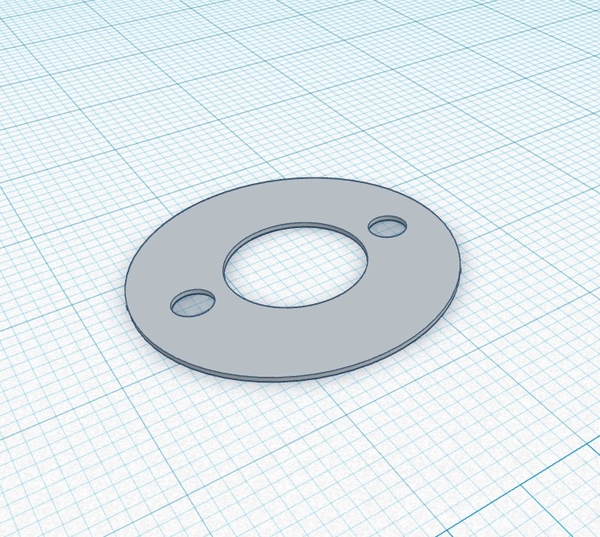

The 3D printed shim was designed to not change the motor angle, which would affect the mesh. Trial and error yielded the correct thickness, I had the motor shimmed out 2mm at one point.

I hope to finish the 1369 vid soon.