The other day during a pleasant operating session, we had an engine come to an abrupt halt on a section of main line. A three foot section of track was dead. But when I put the multimeter on the rails, it showed power.

I pulled out a lighted passenger car. No lights... except when I pushed on the car. Then the lights would illuminate. The MTH Scaletrax lock on I used had come just loose enough to lose contact, but when pressure was applied to the track, then contact was made.

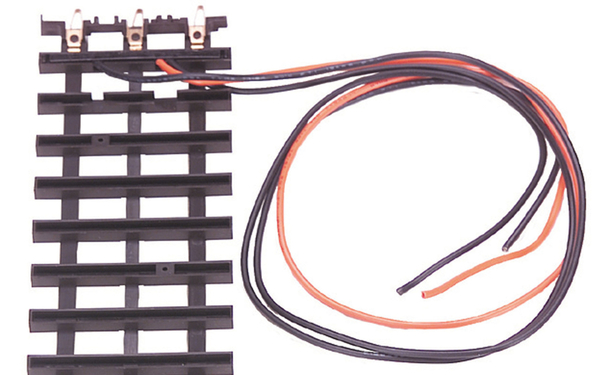

For some back story, we have been building this particular layout since 2012. The mains were the first thing installed so we could run trains. In the beginning, I used MTH Lock On's 45-1033. It's a neat three wire clip that clips into the plastic ties to make contact with the rails. I'm lazy and was not very good at soldering, so I used several of those when I could find them in the hobby shops.

As I read more and more on OGR over the years about soldering track wire leads, I started doing that instead. It was cheaper and it provided a better connection.

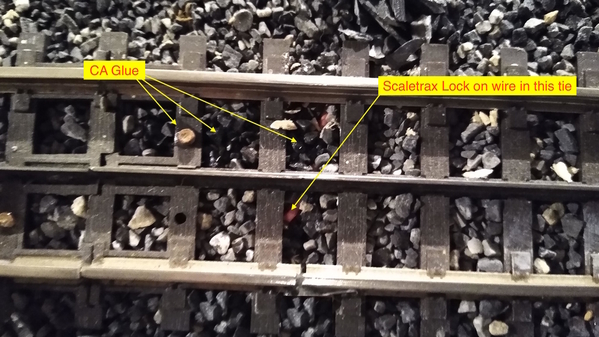

At this dead section of track, I happen to have used one of these lock on's. The problem, it the track was nailed down and ballast had been glued in place. In order to fix this I was going to have to tear things up which did not interest me at all.

What I ended up doing was applying just enough pressure on the rails for the lock on to make contact. Then I applied some CA glue to the area for a quick set. That seemed to work. I'll probably regret that decision if and when the time comes to ever dismantle the layout.

So the point of this long thread is to listen to these kind experienced folks on OGR and solder your track leads. You will have a better connection and you will have access to these connections in the future after you use ballast and glue.

Have Fun!

Ron