I have not worked on a PS-3 2 Rail engine, but I am converting quite a few MTH Scale PS-2 3V 2 Rail - 3 Rail engine to PS-3 for the DCC capability for a club. Here are some observations on the PS-2 3V engines.

First, if your inside the cab of the engine looking Forward, The Right side wheels have the spring loaded plunger assembly for picking up right rail power. The left wheels are solid bearings and pick up left rail power which is Chassis ground. At the engine, the problem is the red wire going to the tether is for center rail pickups which are removed and not used for 2 Rail. The normal Black chassis ground wire IS NOT Chassis ground anymore. It is Right wheel pickup. Hence, the only Track Left Wheel power connects to the tender from the engine via the drawbar and spring for tether engines and spring for drawbar style engines.

WHat I do for the club that will not run these 3 rail anyway, is move the Red wire in the engine to the chassis ground screw. This now provides left wheel power through the tether/drawbar wire. Not just the drawbar spring connection.

For non switcher engines, you also have an axle strap on the trailing truck which is an alternate Right wheel pickup. Make sure the strap actually is in contact with the axle.

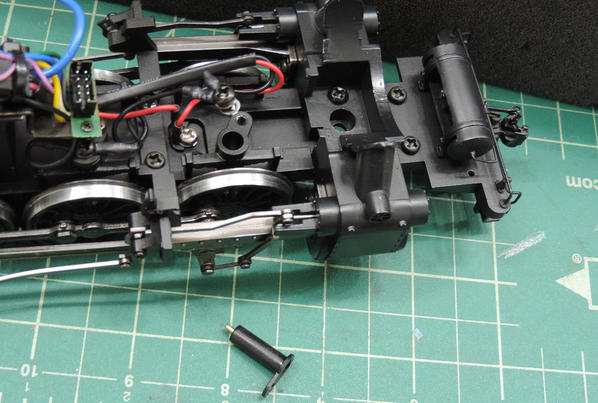

Lastly at the engine, I measure right wheel to right wheel continuity. I had one engine that only had 1 of the 3 powered drivers making contact. What I found was 2 of the copper springs had overheated and annealed, and collapsed. No longer providing pressure on the right bearing. (Currently looking for a source for replacement springs).

Moving to the tender. One truck as plastic bearing on both sides and use a axle strap to pickup right wheel power for the tender. The other truck as metal bearing on left side to pickup chassis ground left wheel power. Unfortunately the other right side uses plastic bearings. Since the right wheels are insulated with plastic bushings, there really is no reason to use plastic bearings on the left wheel pickup truck. They could be replaced with metal bearings to ensure the axle is making good contact with truck frame on both ends.

Inside the tender, the black wire going to switches from the tether harness is right wheel. Gray is left wheel chassis ground. The red wire on the end of the 3 Rail to 2 Rail switch is center rail pickup. Since I repurpose this to be Left side chassis ground I remove it from the switch and move it to the Chassis Ground wire nut.

Again, axle straps on the tender need to contact the axle.

Switchers are a little different in that Pickup rollers are on the tender as the red wire is repurposed as a forward coupler. Therefore no center rail pick up on the engine. For 2 rail most remove the couplers and add kadee couplers. So I repurpose the red wire by adding a jumper wire with terminal that I can attach to a ground screw.

Some pictures below. G