Thank you, Mike, Jay, Justin, Randy, Bob, Marty!!

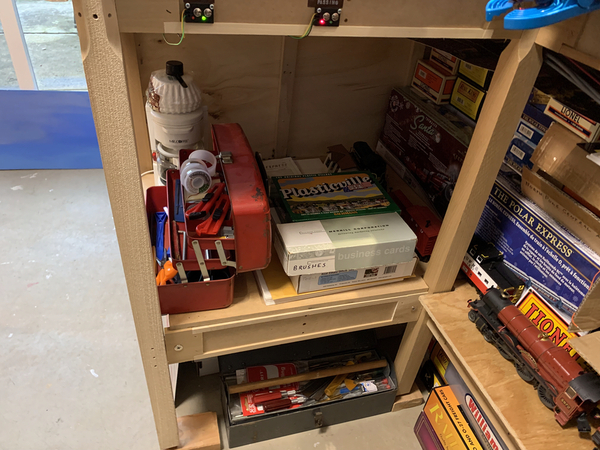

First off, I will address Randy's question, which Bob and Marty replied to. Thank you both for chiming in. For quite a while, I was like you Randy wondering why there weren't any mounting holes, slots, whatever. I made my first board with only a TIU and Base 1 with Velcro just like Bob showed. One day I mentioned the issue on the Forum, and was given the answer Marty shared. Here I thought the holes in the front only allowed you to get a screwdriver in to remove the front of the housing to replace a fuse or whatever. Actually, if you peal off the rubber feet on the back of the TIU and AIU, the hole is already there except I had some flashing on one AIU I had to drill out as Marty showed. Otherwise, you just need a standard Phillips head screwdriver and some self tapping screws, or in a pinch, just press hard on the screwdriver until a regular screw gets a bite into the plywood.

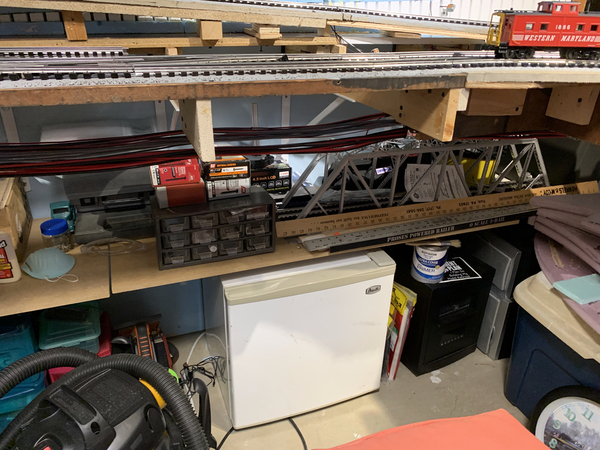

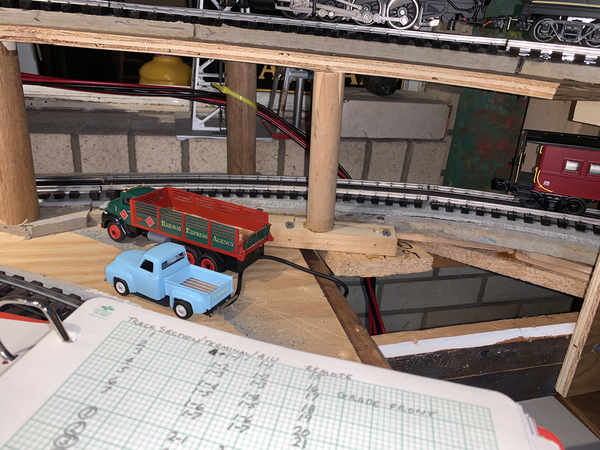

Mike, Thank you. I'm not pulling out the boxes under the layout that are right behind the right side board so you can see all the wires coming in from all over the layout. That was another problem besides running out of room adding to the scope of the layout. They are crisscrossed in a rather haphazard fashion to enter the holes at the top of the panel. Initially, I thought I would put the panel under the layout on the long wall underneath the two grades. However the initial configuration had most of the switches on this one end of the layout, the little yard, engine service area, and one of two passing tracks. I thought I would have less long wires, and this was the spot I could make the two sided board. When I started the reconfiguration, I quickly realized, this wasn't the best spot, but I wasn't about to take everything apart and rerun all the wiring. I have done that before at the power company when we moved 7-1/2 foot tall steel relay panels, and it is a mess to keep all the wiring documentation straight for the electricians. Talk about using a lot of red and green pencils on the drawings!! It can blow your mind!!

Bob, yes I am glad this job is behind me. I have the switch wiring to attack, but that is a project for next winter.

Funny you mention PT. I have completed 5 weeks, and the pain had really improved. There are two issues. I now have new pain in the thigh muscles mostly, but also in the hips when I first get up in the morning. Yes, I have really put the muscles through the paces, so that makes sense. However, I thought I lost strength in the legs. Here the nerves to both legs have stopped responding to what the brain tells them. It is worst going up stairs. So now I am starting on new exercises to "retrain" the nerves as the therapist put it. I am certainly glad I am retired now!!!!!!!  Time to go do my first of 2 daily exercise sessions.

Time to go do my first of 2 daily exercise sessions.