@bmoran4 it might be a workaround. But it doesn't require any special tools or skills (other than soldering.) Zero chance of causing permanent damage, and it's 100% reversible. I'll wager that the modified loco would have better electrical pickup than it did before the failure, so you could consider it a performance upgrade.

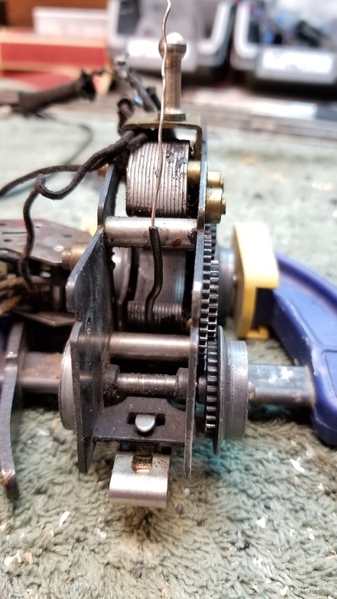

I've replaced these sliding shoes before. New shoes will add a LOT of friction until the V-shaped groove wears in (as shown in the photo.) Also, if the spring tension is too high, they will tend to lift the driving wheels off the rails, further reducing pulling power. Not really a good design. Fully worn shoes or even no shoes are as good as it gets operationally (assuming the tender is used as an alternate source of reliable power and ground.) These issues were corrected in 1950 with the 2036, which got roller pickups like its O gauge brethren.

Regarding the shrink tubing- it might work. But that depends on where the exposed part of the wire is that's causing the short. In the proposed repair, there won't be anything holding the tubing in place. If the shrink-tubing migrates (for example, if the loco is turned upside-down in the box), it could permit a recurrence of the short circuit. So if the OP can't repair the broken wire, then he's better off removing it. I'm more familiar with the wire coming loose from the collector, in which case using shrink tubing is not an option.

I like Doug's idea about soldering a new wire. I don't know how difficult it is to replace the Lionel tag, or whether the metal tabs on the tag would survive being straightened and folded multiple times. Drilling the hole is a permanent modification, but if it's hidden by the tag, who cares!

A lot of folks love Postwar, and Lionel's diesels were amazing feats of engineering. But many of their lower-priced steam locos were very primitive, really just a clockwork chassis retrofitted with a magnetic field. Shame on Lionel for not making the 6-wheel parallel plate chassis more user-serviceable. IMO it should have been assembled like the Standard gauge bild-a-loco motor. But it isn't. So replacing wheels, gears, and the collector plate are all basically a service station-level repair.