For me model railroading is a work-in-progress because I make changes as I learn and grow from experience. By way of laying out this evolution I will post what I did on the Plywood Empire Route to this thread, updating from time-to-time as I make changes, additions and tweaks. Also by way of laying it out I will go back and move previous content of mine to this thread as well. This way too, no one need be upset by me cluttering things with an occasional family photo or story because anyone so minded simply needn’t view this thread.

I’ll start with a couple pics of PER 1.0.

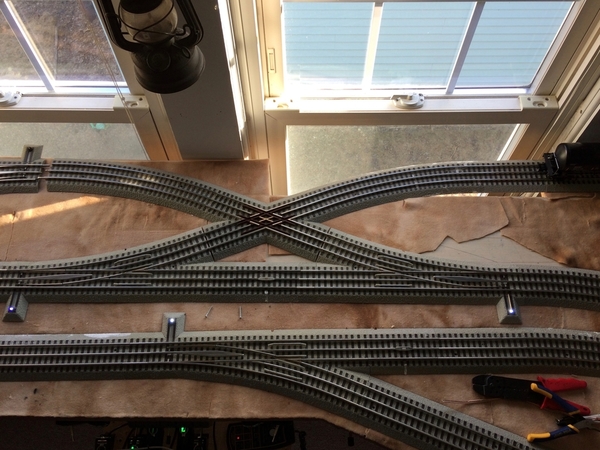

I started with the familiar switchman's nightmare with a short run-around track and a switchback siding.

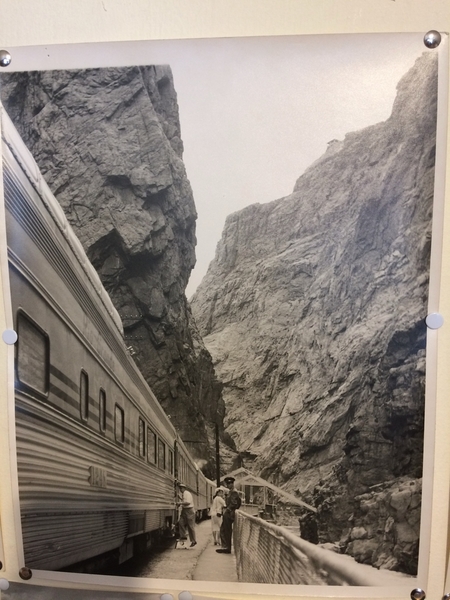

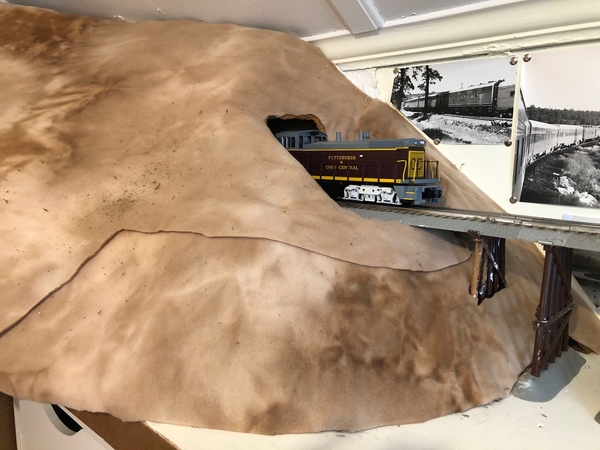

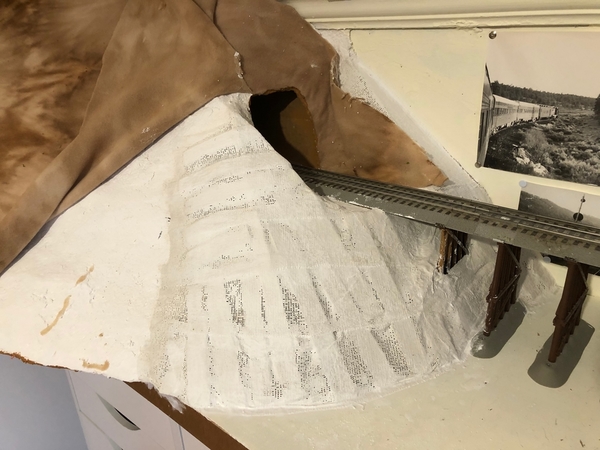

The beginning of Mt Crumpet:

I quickly learned that for me the switchman's nightmare was boring and stressful so I began tweaking:

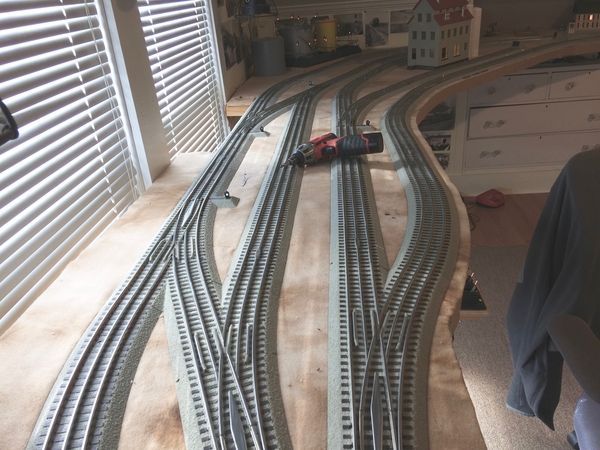

This iteration, (call it PER 1.5) had a long passing siding and one industry at the East End and two industries at the West End:

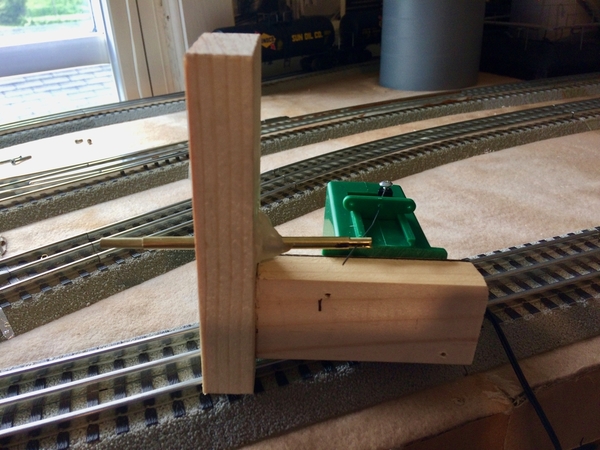

But, with a lot of drilling going on that S curve (at the left) was awkward. In this pic a second stub siding had been added. The S curve:

Fixed:

The second siding did nothing so I ripped up one stub siding:

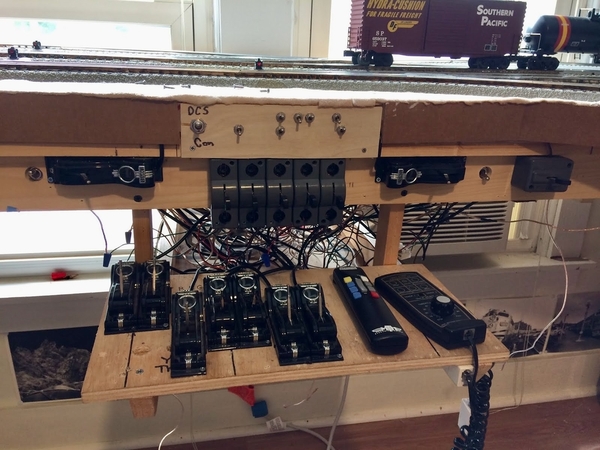

Upon examination I decided to move the runaround track leftward to a much more natural position immediately beside the mainline thus creating a proper passing siding appearance. Of course I had to move the paint factory and shorten what had been the runaround into a stub spur. A more railroad-like looking trackplan with no loss of operation potential. I liked the West End this way: