A number of folks ask me about solutions for creating puffing smoke when doing TMCC upgrades, or for that matter, to upgrade an older TMCC locomotive with fan driven smoke. I've done it a couple of ways.

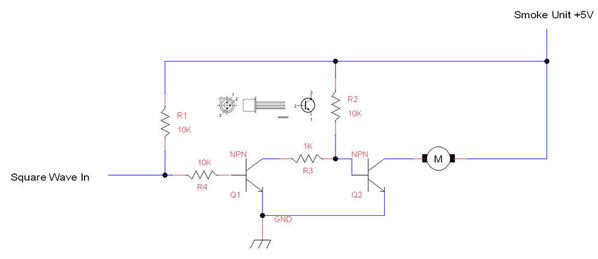

The first method is to simply buffer the chuff signal from the chuff switch and drive the motor with the buffered signal to avoid any possibility of feedback to the RailSounds chuff input from the motor that would potentially damage the input circuit. That circuit is illustrated below. I use the 5V supply that's already on the fan driven smoke unit to power the circuit as the only real current requirement is still the motor, and now it's not running continuously. The SQUARE WAVE IN is the chuff input, as you can probably tell, I lifted the circuit starting point from another project. ![]() This circuit is running around in a number of locomotives and works just fine.

This circuit is running around in a number of locomotives and works just fine.

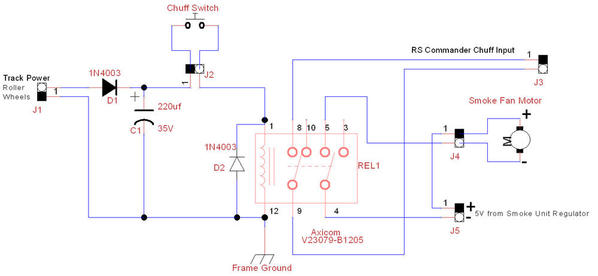

A new winkle developed when the new RailSounds 5 boards were released by ERR. If you read the documentation, they are pretty adamant about having a dedicated chuff switch driving the board and not having either lead common to anything. That presents a little problem for my buffer circuit. Given that limitation, I decided to come up with an alternative that would provide the fan control and a totally isolated output for the RS board. The result of that search is presented below, I found a suitable relay in my parts box and slapped this together. It works great and solves the isolation issue. I've built a couple of these so far, and one day I may pick a smaller footprint relay and commit this to a PCB. The relay has a 24 volt DC coil and is a perfect match for 18 volt track voltage, when rectified and filtered, I get around 25 VDC to drive the relay. This relay only takes six milliamps for the coil, so it's real easy on the reed switch.

I hope these ideas are useful for folks doing upgrades and wanting chuffing smoke.