Dave,

Sorry, I’m mixed up the 2” with the 3” distance for the top left corner and thought the bench work was tilted more than it is. After taking another look at the measurements you posted, your current bench work is only off by .1”, so it might be off by .2” by the time the track reaches the far side of the office. I got the 2.13” on the left side mixed up with the 3.19” on the top. The top edge is 3.19” on the left and 3.29” on the right, so not a big deal. Plus, the latest version no longer moves the track closer to the top wall in the office room.

The track next to the dividing wall still bothers me a bit only because I’m not the one laying the track. 🤪 I’m not suggesting you buy an expensive engine. If John says his Big Boy navigates 3.5” from the wall, I believe him. So, if you make sure the center rail of track along the dividing wall is 3.5” from the wall, and any rock molding you add, I’m confident the Big Boy will work just fine. I just don’t like working with minimal clearances when it’s not me doing the work or having to deal with potential problems.

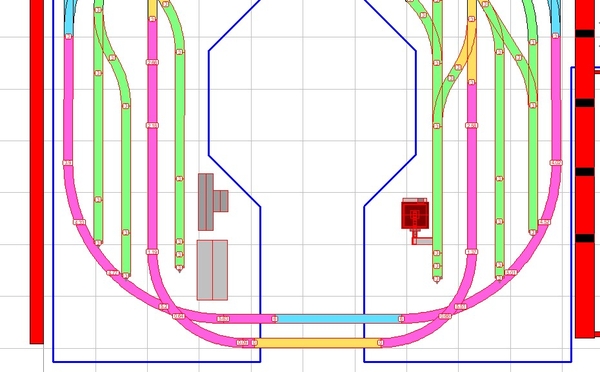

I also get nervous whenever there are cut tracks involved because you can’t completely dry fit things. There are 5 cuts tracks in the outer blue ring alone, on both the length and width. The top cut piece is 11.25” whereas the bottom cut piece is 11.92”, a 3/4” discrepancy. I assume that’s because the top connects to an O-72 switch and not a sectional O-72 curve like on bottom, but I don’t know that that’s the reason. If I replace the switch with a curve, it fits, so why are the cut pieces different lengths? I don’t like questions I can’t answer. 😱

And then there are the 2 cut curves on the inner blue arc with the double crossover. To cut those, the double crossover, 3” straights and curves leading up to the cut tracks have to be laid correctly. And those 2 cuts should be the same, they’re very close to a half curve. I have no doubt you’ll get it all connected, just pointing out areas of concern.

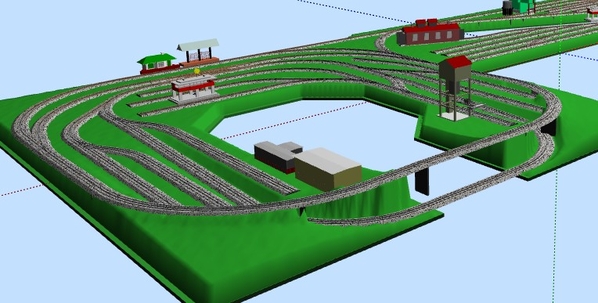

As far as roadbed, etc., are concerned, people who can find and afford Homasote either cover the whole layout or just put it under the tracks to cut down on noise. Cutting it is dusty and cutting it to just go under the tracks is probably wasteful. In your case with so much track, I don’t think it makes much sense to cut it. When it comes to foam, it’s used mainly to sculpture valleys and rivers. Again, some people cover the whole layout with 1”-2” foam. That’s mostly folks like you who build a flat table top. If you want a valley or river below track level, the track level has to be raised or the bench work built with varying elevations. If you recall what Tom said about an over/under, he said not all track has to go up 6” to make a 6” separation. Some track can go down 3” and the rest go up 3” for a total of 6”. Again, the main track can be raised 3” using foam, so some cam go down and others go up. Many who plan to have elevation changes use L-girder bench work with cookie-cutter sub-roadbed. But, it wouldn’t make sense to change what you have. However, if you intend to pursue elevation changes, you need to plan for that now. Early on I posted a design with the lower blue tracks lowered and the orange raised to where the blue track went under the orange track. I think I also showed just the bottom blue track raised. I think the amount was like 3” because you only have so much track after switches to work with. And if you decide to add foam, that affects how the wall gets opened. Some stuff you won’t be able to do if you don’t plan ahead.

One last thing. I don’t know if SCARM is designed to print to scale using anything but standard letter-apsides paper, so something to check.