OK, here's some results:

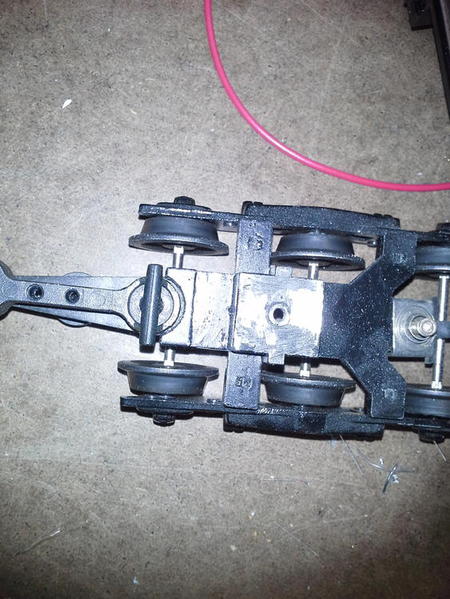

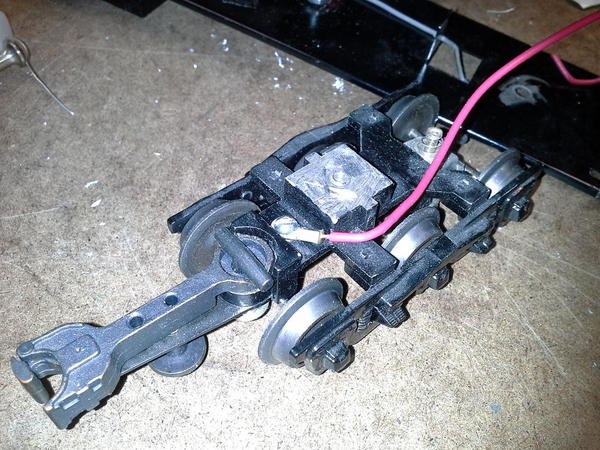

I was right about the ground. The 2nd car I converted, a Williams madison-style observation care, is the one with 2 grain-of-wheat bulbs. I would not call them power hungry, and they work fine tied into the 10.1 volt regulated power supply they share with two strips of led lights. (This is one benefit of setting up the regulators to provide constant voltage rather than constant current---I can turn out a bunch of them and use them interchangeably for various lighting loads. I removed the trucks. They & the frame are heavily painted. I used a moto-tool with drum sander to remove all the paint from the area where they mount--top of the trucks and bottom & top of the frame by the hole. Vast improvement, for now there are more paths for ground. Now the lights only flash off---not flicker--- where the center rail has dirt; when I wipe the center rail with Brakleen, a lot of dirt comes off and the lights don't cut off.

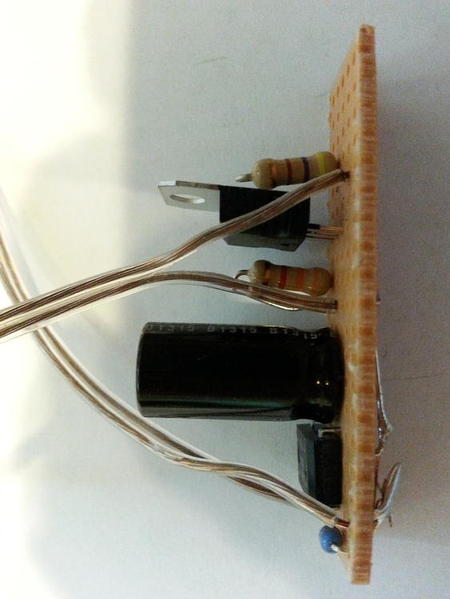

The adjoining car, which is the first I converted, has the lights go out often, especially on curves. I intend to remove the trucks and do the same. Both cars have 470mfd capacitors.

I intend to do the remaining pair of Williams Madison cars and a 5-car Williams streamliner, and then turn to the cabeese. I do not intend to tackle my 9-car MTH passenger set, since the stock lighting is even and flicker-free.

Stan: My track voltage is about 18VAC. I haven't measured the voltage with the car on the track, but I can tell you that on my workbench, applying 10 VAC to the rectifier input, with a 1000mfd cap, will yield about 13 VDC.

Given that I'm using 2 LED strips in a car, it may well be that a 470mfd cap can't provide power for a long enough period. As I said, the lights do out when there is a very brief power outage. There is no flicker (which I define as a constantly changing brightness) in the converted cars, which is quite evident in the unconverted incandescent cars. It is possible, of course, to put a very large capacitor in the rectifier output to provide power for a longer period. But I'd rather address the crux of the issue, the poor ground, rather than just mask it with a larger cap.

It would probably be best to drill and tap each truck for a very small screw, to hold a #24 wire connected to the frame. 24 gauge should carry enough current for the LED lighting.