Sorry, I hit post too soon.

You can see that I have the seams still open on the background. It was necessary to re-hang the sections a few times as they acclimated and stretched over the last couple of months. The section on the short wall still needs a little work.

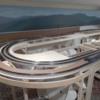

The front track is mostly re-used Atlas O. All of the curves are GG flex track.

I will need to build a cross over section here for the first level. The second level will also cross here but in the other direction. I'm thinking this is a good place for a drop down for access to the corner where staging tracks will be.

I have changed some of the design by moving more switches out from hidden areas. I also added the capability to run a train in a circle so I can wire up the drops that are in place now and run my train while I work on the rest.