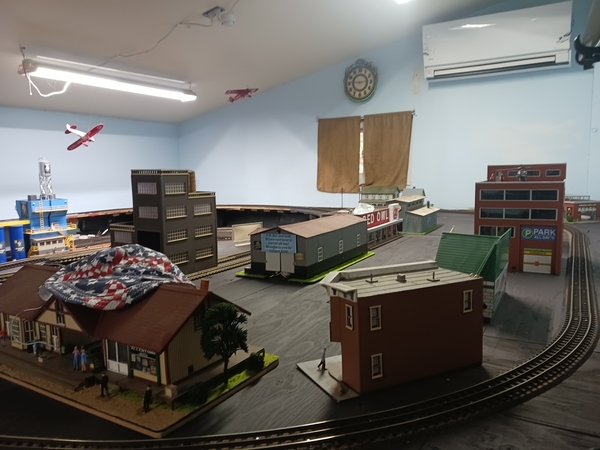

Well, while technically not ON the layout, my latest project will eventually be featured there, so I guess this qualifies!

In its current form, this project is really the latest iteration of several on-going projects and guiding development principles, including my on-going "button" project (coming up with button-activated features to amuse the grandkids), my continuing efforts to recycle and repurpose old materials and electronics, and my frequent efforts to utilize non-train-related items on the layout.

So, what is the project? After a lot of contemplation and false starts, it has evolved into a set of renewable-energy-themed features, including an operating windmill, two working solar panels, and a solar and wind powered billboard.

Specifically, I came across an inexpensive solar-powered model windmill on line a month or two ago, and ordered one after discovering it was close enough to O scale (at least by the loose "Big L" standards!) to be considered for incorporation into the layout. It worked as advertised, but needed direct sunlight or very bright artificial light (both in short supply near my basement layout!) directly on the solar cell in the base to operate. I found the windmill's motor would instead run on other sources as long as they provided as little as a volt and a half, and no more than 3 or 4 volts (not coincidentally roughly the output of the OEM solar cell) before it spun too fast. So, I needed an alternate power source.

By chance, I had recently replaced a pair of solar spotlights, which I had deconstructed earlier with the intention of salvaging the LED spots and adding them to the Arduino based "thunderstorm simulation" I had put together and installed on the layout. Among the remnants left over were a pair of solar cells and two rechargeable batteries. The solar cells were each nicely mounted in a rectangular plastic case, which when opened left the cell in a flat rectangular surround resembling a solar array. Bingo! A bit of fiddling, and I was able to confirm the cells still produced usable power (enough to spin the windmill), and came up with a plan to mount each of them on a stalk, like some prototype solar arrays.

For kid-friendly light sources that could be directed toward the solar cells on the layout, I decided to use some LED flashlights I had on hand, but they were not quite bright enough to reliably spin the windmill. So, I tried to come up with some alternate or supplemental power source. As it happened, both the rechargeable batteries and a standard alkaline AA battery had enough juice to spin the windmill, so I decided to add a button under the edge of the layout (like the one in this video) to send extra battery juice to the windmill.

While all this was in progress, my thoughts turned to alternate ways to use and display the energy I'd be generating and/or supplementing. Recently, I was sent a 100-pack of the wrong type of LEDs, so I checked to see if they could be powered by my devices. Bingo again! A little more thought, and I came up with a foam board construction surrounding sixteen color-changing and flashing LEDs chained together to provide a backlight for a renewable-themed billboard, which will light up whenever the solar cells are generating or the supplemental power button is pressed. I finished the LED string fabrication last night (some of the most fiddly soldering I've ever had to do BTW!) and everything worked! Now I'm waiting for the glue to dry, so I can close it all up. Here's a video of the LEDs in operation, behind the gloss finish laser printed renewable energy graphic I plan to use as the billboard pic:

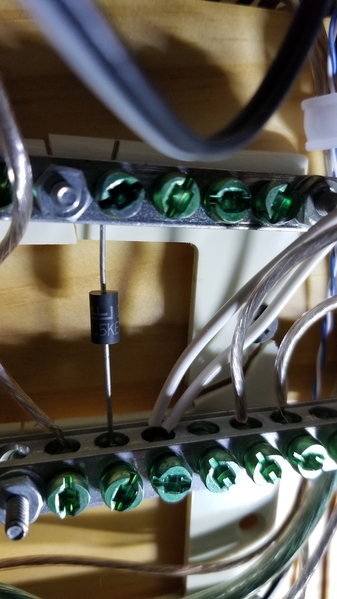

Meanwhile, I discovered that a single alkaline cell was not powerful enough to light the new sign, so I settled on the nominal 3.2 volt rechargeable cell instead. The only problem: they must be recharged eventually, there's no recharger, and the push button's LED would create a small but continuous drain, resulting in eventual discharge of the battery!

A bit of research, and I found the retired solar spotlight's 3.2 volt Lithium Iron Phosphate cell needed a recharge voltage of between 3.5 and 3.65 volts. Easy-peasy -- I cut the molded battery holder free from the old enclosure, connected it to an AC to DC voltage converter (which I set to 3.58 volts), and voila!, the rechargeable battery recharged (from less than three volts to 3.26 volts) in a matter of minutes. There's also a slide switch from the remnants I may be able to use to easily disconnect the battery when not in use.

So, as currently planned, I will end up with a roughly scale windmill, two pedestal-mounted solar panels, and a "solar powered" and renewable-energy-themed billboard, which can be activated (windmill turns, billboard lights up) when either beams of light are focused on the solar panels, or the under-layout button is pushed. Stay tuned . . .

![]() We are going to be building a 315 KW solar PV system on one of our buildings later this year.

We are going to be building a 315 KW solar PV system on one of our buildings later this year.