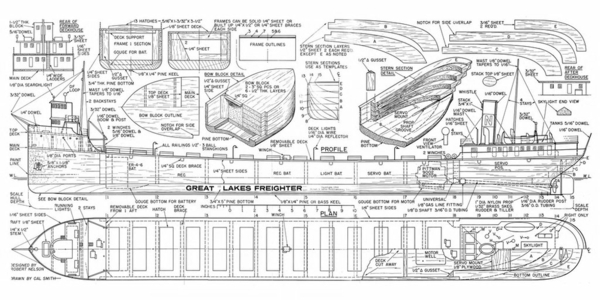

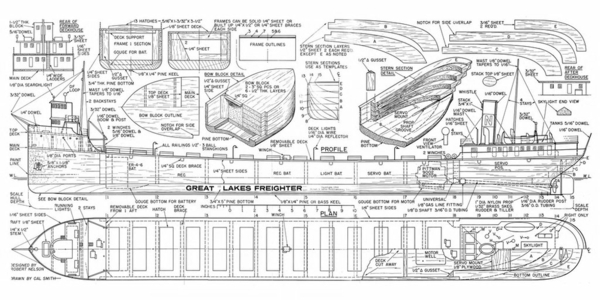

I haven't posted anything in a LONG time because I was working for the past 5 months on a Great Lakes ore boat for my harbor area. It all started with an idea and a set of plans I purchased from the Bay. The boat is nearly 375 scale feet long and 50 feet wide in 1/50 scale. LOA is 92 X 10 inches. Plans were 1/100th and I enlarged them 2X on my printer.

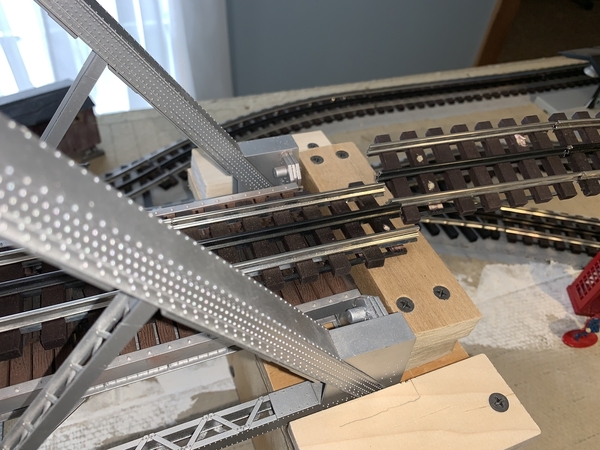

The keel is a piece of 1X10X1/2" OSB to which I screwed and glued 1/2X4" poplar. The bow and stern was made from 3/4" aspen rough cut with a coping saw, sandwiched together then all hand carved using only a 1-1/2 inch chisel.

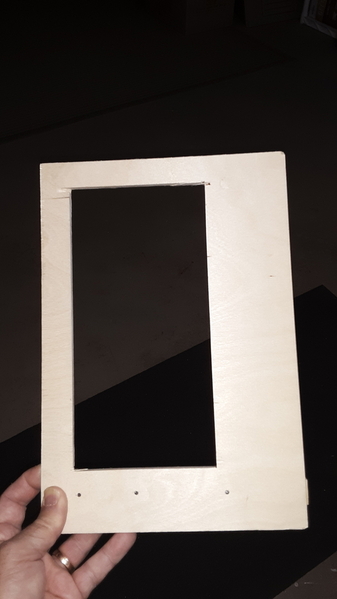

Afterwards they were attached to the hull with many screws and wood glue. The deck is a piece of 1/8 inch hardboard glued and nail down to the hull. Holes were cut into the deck using a home made jig and a Mototool and a spiral up cutting bit.

The entire boat was skinned with 0.020 styrene I had from when I worked for K Mart that were signs they used to promote flu shots. They were attached with contact cement.

The forecastle and stern cabins were made from foam board also skinned with styrene. The boat is nearly 99% scatch built with the only commercial pieces are the windows and doors on the cabins coming from old lionel 4 wheel bobber cabooses, the hatches from the same (cupola roofs), and the handrail stanchions and stairs from a Plasticville coaling station with hand formed rails. The smoke stack is a piece of plumbing pipe, masts are dowels. The ore load in the hold is Styrofoam insulation formed into mounds then covered with plaster soaked handi-wipes.

Painting was accomplished using rattle cans with appropriate masking. The boat was then set into position and water was built up around it using white glue and toilet paper for waves then coated with 5 coats of gloss water based acrylic finish.

I still have a little bit of work on it, finishing the railings and adding a smoke unit to the stack.

I christened the boat the Kermit Lesocki, for our pest control guy's dog that passed away last year. He was influential in getting my wife to open the purse strings and let me build my layout.

I was a little bit long winded but open you like it. Have many more photos but don't want to overload the post.