Really nice looking, Jeff!

@Alex M posted:

Wow, outstanding work Alex! Very nice. What did you use for lights inside?

Steve. I just passed the Boars Head truck coming home and said that would be a nice vehicle.

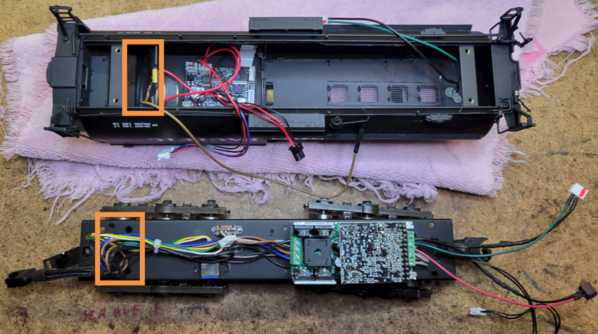

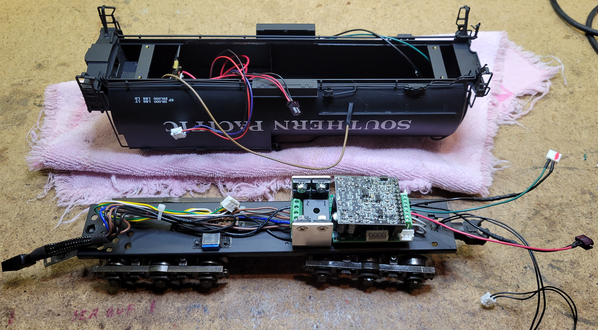

I thought I was finally going to say the F3 was off the workbench, and then this happened.....I was testing the engine last night and the front motor was stalling on the curves, hmmmmm......

Upon closer inspection I discovered that one of the motor leads was broken and hiding under melted insulation. 🤯🤯

I guess all of the handling while I've been working on it caused the wire to break. A quick trip to the soldering station and we have restored full power.

Just need to drop the shell on and call it done. 🤞🤞

The shop foreman is getting a little antsy and wants this job done. More jobs are waiting and the customers are getting impatient. 😂😂

Bob

Attachments

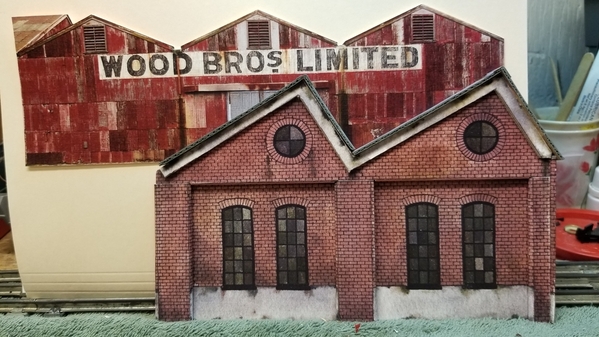

Paper model from the August 1953 issue of Toy Trains magazine:

A signal tower, slightly modified from Hal Carstens design.

PD

@DMASSO posted:Steve. I just passed the Boars Head truck coming home and said that would be a nice vehicle.

Getting ready for the MTH Pup Trailers - 20-95522 BEDT METCA

Converting the Ford C, it's all I have to work with for the 70's. Guess they skipped a few generations?

Made some refrigeration units for them and the Ford... ![]()

@pd posted:Paper model from the August 1953 issue of Toy Trains magazine:

A signal tower, slightly modified from Hal Carstens design.

PD

Nice! ![]()

I convinced after 8 layouts since 1963, paper is the only way to achieve a real look. Plus you can customize it on the PC the way you want!

@RSJB18 posted:I thought I was finally going to say the F3 was off the workbench, and then this happened.....I was testing the engine last night and the front motor was stalling on the curves, hmmmmm......

Upon closer inspection I discovered that one of the motor leads was broken and hiding under melted insulation. 🤯🤯

I guess all of the handling while I've been working on it caused the wire to break. A quick trip to the soldering station and we have restored full power.

Just need to drop the shell on and call it done. 🤞🤞

The shop foreman is getting a little antsy and wants this job done. More jobs are waiting and the customers are getting impatient. 😂😂

Bob

Bob make sure the motor brush leads have plenty of freedom for movement,….if they’re too snugged up in those zip ties, you’ll have a repeat offender,…..then somebody in the shop is gonna be looking for employment,…..😜

Pat

@SIRT posted:Nice!

I convinced after 8 layouts since 1963, paper is the only way to achieve a real look. Plus you can customize it on the PC the way you want!

@pd posted:Paper model from the August 1953 issue of Toy Trains magazine:

A signal tower, slightly modified from Hal Carstens design.

PD

I love paper models. Easy to work with and customizable.

This flat is all printed on cardstock. The fence is also a print, I added balsa for the stringers and posts.

Attachments

@harmonyards posted:Bob make sure the motor brush leads have plenty of freedom for movement,….if they’re too snugged up in those zip ties, you’ll have a repeat offender,…..then somebody in the shop is gonna be looking for employment,…..😜

Pat

That's what I've been struggling with Pat. The clearance around the front pull-mor has been giving me fits......![]()

Some genius in the shop decided to add a cab and figures, which has made wire management a royal PITA! ![]()

Bob

@RSJB18 posted:

I like paper models, too - yet I have never gotten into actually doing any. Strange. Only so much I can do.

"Realistic" lithography falls into a similar category for me (think Mark 3/16" scale rolling stock); 2 dimensions realistically emulating 3 is an interesting thought.

Very nice.

Here's another paper model, also from Toy Trains magazine, the Parlor Flats depot:

Again, a few modifications, adding a small platform and a functional signal.

Paper models are great. Best part is if you foul it up, just reprint the bits and start over.

PD

@RSJB18 posted:That's what I've been struggling with Pat. The clearance around the front pull-mor has been giving me fits......

Some genius in the shop decided to add a cab and figures, which has made wire management a royal PITA!

Bob

Did you contact engineering about changes made on the shop floor with out submitted engineered plans?…….sounds like corporate is going to be doing a shop tour,….people’s livelihoods are at stake !…..Chop chop!,….I expect a full report by morning,…..😉

Pat

Take an MTH Illinois Central GP9 shell, an MTH GN GP9 PS1 frame with trucks, a mini-commander, and make a dummy with coil couplers. Maybe later on I can figure out the lights; the frame came without, not sure what I am missing or looking for.

@harmonyards posted:Did you contact engineering about changes made on the shop floor with out submitted engineered plans?…….sounds like corporate is going to be doing a shop tour,….people’s livelihoods are at stake !…..Chop chop!,….I expect a full report by morning,…..😉

Pat

Funny you should say that Pat. My former boss was fresh out of Pratt Institute with his engineering degree. He took a job at Grumman Aerospace here on LI in Liaison Engineering. When he interviewed for the job, he asked what the group does. His future boss told him that they work with the mechanics out on the assembly lines troubleshooting issues that come up in construction. At the time, Grumman was early in their Navy contract for the F-14 Tomcat. He told us a story of trying to figure out how to route fuel lines through a wing because the design engineers forgot to cut ports in the ribs of the titanium wing struts. ![]() Needless to say, he had a lot of fun......

Needless to say, he had a lot of fun......

And for the record on my F3, updated shop drawings have been submitted for approval. ![]()

Bob

@RSJB18 posted:Funny you should say that Pat. My former boss was fresh out of Pratt Institute with his engineering degree. He took a job at Grumman Aerospace here on LI in Liaison Engineering. When he interviewed for the job, he asked what the group does. His future boss told him that they work with the mechanics out on the assembly lines troubleshooting issues that come up in construction. At the time, Grumman was early in their Navy contract for the F-14 Tomcat. He told us a story of trying to figure out how to route fuel lines through a wing because the design engineers forgot to cut ports in the ribs of the titanium wing struts.

Needless to say, he had a lot of fun......

And for the record on my F3, updated shop drawings have been submitted for approval.

Bob

This was a tough assignment Bob, but that’s why you got it,….but, we don’t anticipate results, we rely on them…..obviously corporate still has an eye on your team, …..as soon as your team is successful, we’ll reward your hard work with something harder to do, …..I’ll expect a fast track of design, & implementation by close of business today, with testing by morning,……When I worked in engineering at Ford Motor Co., that kind of word soup was driven in our heads 6 days a week……🤮

Pat

Sirt, I was hoping to see the results by the time I got to the end of this thread and Voila! You never disappoint.

@harmonyards posted:This was a tough assignment Bob, but that’s why you got it,….but, we don’t anticipate results, we rely on them…..obviously corporate still has an eye on your team, …..as soon as your team is successful, we’ll reward your hard work with something harder to do, …..I’ll expect a fast track of design, & implementation by close of business today, with testing by morning,……When I worked in engineering at Ford Motor Co., that kind of word soup was driven in our heads 6 days a week……🤮

Pat

So the senior shop foreman was called to the floor. He usually sits in his office all day and pretends to be busy. He was asked to review clearance issues with the front truck. Despite the team's best efforts to re reroute the wiring the issues persisted.

Well , the old pro discovered that the cab was installed on the wrong mounts and was causing the motor to bind on curves. He immediately instructed the crew to shift the cab forward by approximately 1/8" which solved the clearance issues.

So with that finally behind us...the final assembly can be completed. 🤪🤪

Revised shop drawings have been submitted.

At least he didn't need to consult with Liasson Engineering. 😂😂😂

Bob

Are the Paper Models you referenced still readily available for re-printing?

What is the source you use to obtain them?

@Craftech posted:Nice,

John

Thanks John. The prints come from a guy in the UK who runs a model RR blog. Mostly N and HO but some of us O gauge guys chime in from time to time. I can send you the link if you are interested, email is in my profile.

Bob

I found these. Maybe Bob can tell you if they are any good.

https://steamtraininfo.com/why-carton-models

https://modelrailwayengineer.c...-card-building-kits/

http://clevermodels.squarespace.com/

https://www.thesprucecrafts.co...veral-scales-2366289

John

@Craftech posted:I found these. Maybe Bob can tell you if they are any good.

https://steamtraininfo.com/why-carton-models

https://modelrailwayengineer.c...-card-building-kits/

http://clevermodels.squarespace.com/

https://www.thesprucecrafts.co...veral-scales-2366289

John

Here's the site I found the prints on.

I have the parts and pieces of four Weaver offset 2-bay hoppers on the bench. This eBay find is providing me the opportunity to expand my Hart ballast hopper fleet. These lightly used Pennsylvania hoppers arrived in good condition but a couple parts needed some miner brass repair. The old markings were removed with SCALECOAT II - Wash Away. The original discharge chutes have been cut away and new styrene flooring is ready to support side chutes which will be fabricated in the coming days.

Cheers, Dave

Attachments

Dave, "The original discharge chutes have been cut away and new styrene flooring is ready to support side chutes which will be fabricated in the coming days.", I'll be looking forward to see your progress.

Yes Joe! I want to see how Dave does these also!

@Mark Boyce posted:Yes Joe! I want to see how Dave does these also!

Still chipping away at the bench which is now the center of my train activity. I am working on the discharge hatches for the Hart hoppers. The frame pieces are cut from 1mm styrene sheets. This time I am including the center drop hatche but when viewed trackside, the hoppers won’t look any different from the first set I made.

To help align the pieces I use a simple jig. This helps to measure, place, and replicate while keeping everything plumb and square.

The work on the outside hatch is a little more detailed. With the addition of 3/16 U channel, 3/32’ tubing and 1mm square plastic rod, I am trying to create the illusion of a functional hatch. Works for me! What I love about 3-rail - Nobody is going to come over and count rivets!

I’m currently 1/4 of the way through the hatch work. Twelve more to go!

Cheers, Dave

Attachments

Very nice looking work, Dave!

@Darrell posted:

Looks good Darrell . That GRJ is the man . ![]()

Following the recent fleet additions, some upgrades were undertaken. To get 62 closer to the real life prototype, the underbody from a B&O car with 6 wheel trucks was swapped with the as manufactured 4 wheel trucks. And since it was opened up anyways, I took the opportunity to add some additional passengers. Maybe I'll have to get a ghost for it at some point.

Attachments

Wrapping up a 3rd Rail 4-10-2 TMCC Upgrade. Addressing one of my pet peeves, the spaghetti wiring between the chassis and the shell. I like a single connector to separate the two. In the shell is the Super-Chuffer, obviously the smoke unit and the lighting. The Chuff-Generator and tether wiring is in the frame, and any necessary wiring is in the single cable between them.

The tender shell has the speaker, sound board, and obviously the lighting. The Vanderbilt tenders are "interesting" to cram all the stuff in and make it reasonably neat and easy to work on. I mount the sound board on Velcro to make it easy to remove in case that's necessary.

Attachments

Would love to see that locomotive run when finished, GunRunner. ![]()

Oops, it's back in the box to go to the customer. ![]() I guess I should have shot a little video.

I guess I should have shot a little video.

GRJ....little curious about the speaker location. How are you getting the sound out?

Richard

@Rppoind posted:GRJ....little curious about the speaker location. How are you getting the sound out?

Note sound exits front of speaker and holes are directly below, see markings. Given the size and shape of the tender, it's probably about as good as they could do. This is the standard configuration for 3rd Rail Vanderbilt tenders of that era. It actually doesn't do at all bad...