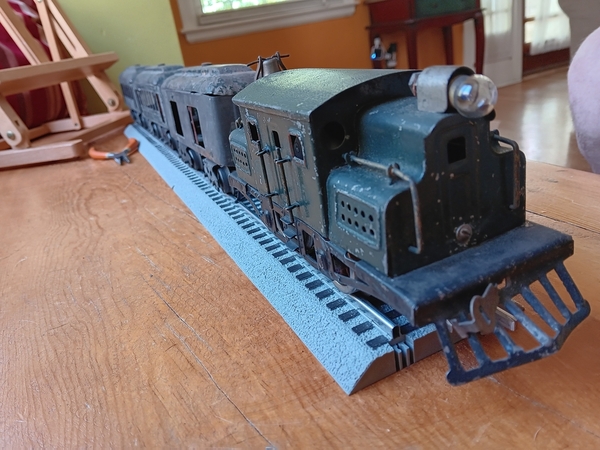

@coach joe posted:Workbench updates. I showed this photo of a K-Line gondola with the accessory high ends and floor after I painted them and added them.

Well upon closer inspection with the floor installed the high ends rode a little higher than they should have.

The underside of the floor shows why. These little "feet" had to go.

A few quick strokes with a razor saw and we have a better fit.

The foam cradle had to be altered

Coach, ….I need that gondola in my life!……beautiful work coach!

Pat