Hey Dallas: Thanks for the kind words.

When it comes to early PS1 boards, they are very finnicky, and will only respond to certain transformers. I already have a long post on the forum about this specific subject. As I've said many times before......it's one of the many mysteries of life!!!

Gunrunner John: Thanks for the info on the headlight power points on the PS! boards. Still not 100% sure on what is what, and is the power AC or DC at these plug points???

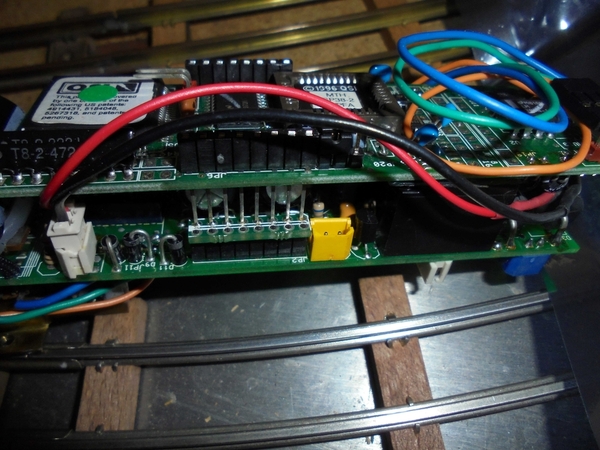

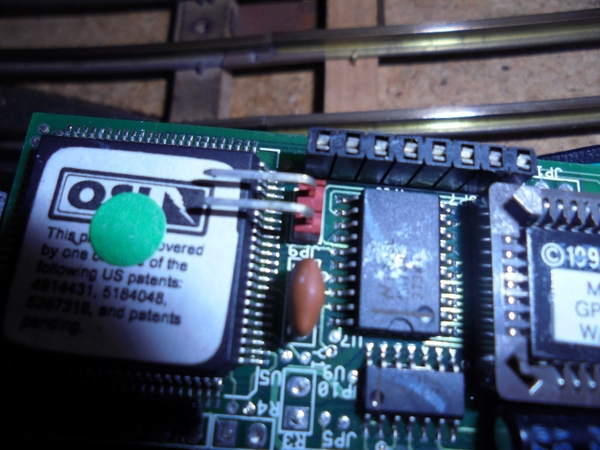

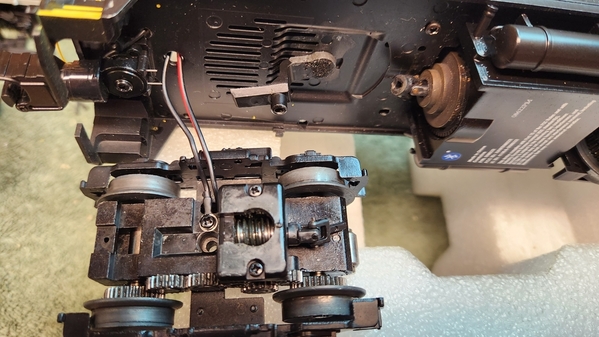

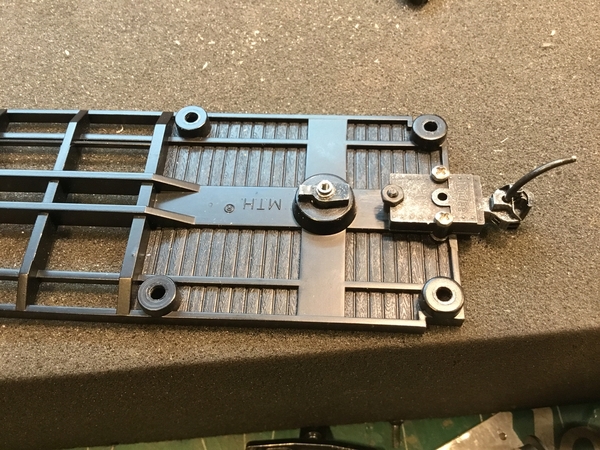

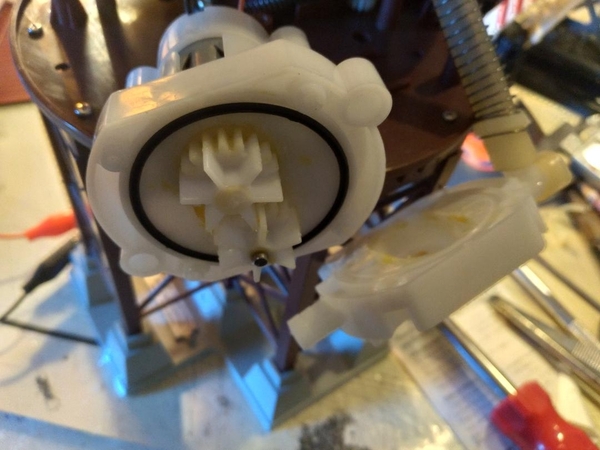

I have included a couple of photos of one of the PS1 boards you recently sent me (got them yesterday). Can you tell me which plugs activate the forward headligh,t and which one activates the reverse light??

There is also a Yellow plug sandwiched between the two boards....what is its purpose???

Finally, there is a second set of prongs on the top board (similar to the speaker prongs) overhanging the micro processer.....what is their purpose???

John, thank you once again for all of your help in the past.....I really appreciate it.

Peter....Buco Australia