Pay no attention to the controls behind the curtain.

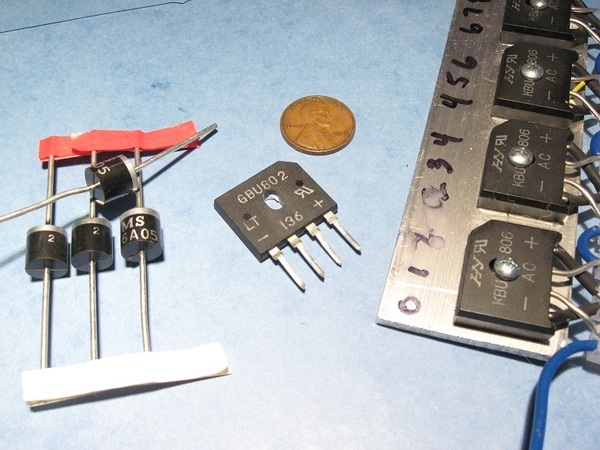

The diode is often the most convenient way for me. I usually have something suitible like that laying around. I haven't bought any in years they are so easily salvaged (?...were easy anyhow; with micro electronics and surface mounts it's a pita. I haven't had anything "new-new" apart lately to see what's more common lately.)

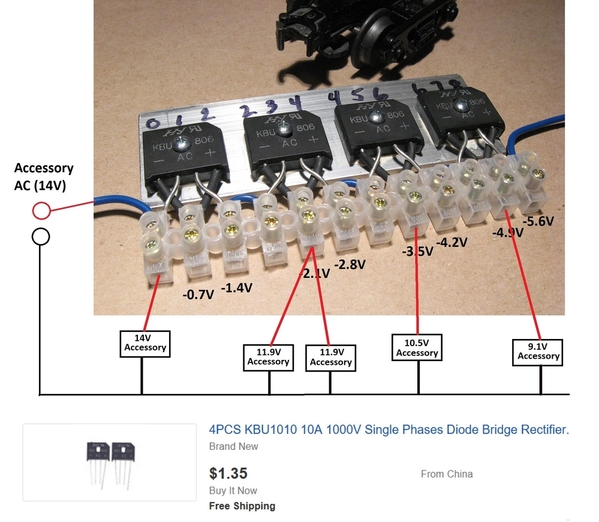

Here are my throttles for a small constant output 12v R.Shack unit that I bet powered a whole lot of home-mounted mobile CB radios across the U.S in the 70s.

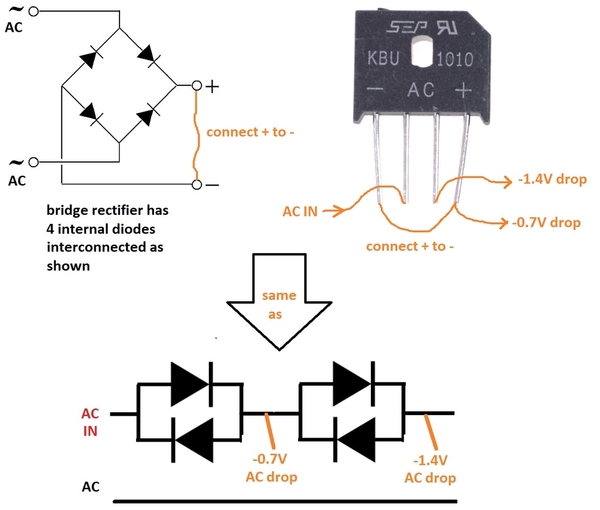

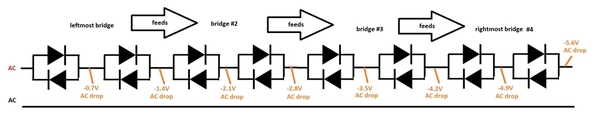

It's throttle is a mix of 2 and 3 postion toggles in 2 old project boxes. Each sw. just adds in a barrel type diode or two in series, with a max of 4 diodes on the far left 3 pos switch (coarsest) Each diode is mounted right on the switch terminals.

Not "free" free, but "what's-on-hand" kind of free.

The diodes are not even the same type, size, or brand. They range 4-8 amps (4.5a supply). Im only interested in the voltage drop they have. I had to test and shuffle them so the left switches are coarser drops; they have a larger volt drop than the switches to the right do.

(I get away with the .5a overage by knowing all my motor draws and appoximating adding the car light amps to have 3.3a constant or lower; peaks at about 4a draw maybe a tad over. It is also pretty much always the last diode to be added in, and going that slow, derailing and shorting to 4.5a trip of the breaker is kinds unlikely as a scenario. (big deal, I lose one speed check IF it fries... till replaced, I'll still run anyhow)

Most of the heavy diodes ate more voltage, but not always. There are two 6a that are very efficient, only one 4a is cleaner. Cooler too so I kinda wonder who's it is and the family type. Unfortunately it also stands the best chance at failure being 4a.

It is more intuitive to use than you might expect too. Partially because of very predictable drops, partially because of center off on either of two switches on the ends, partially from simple up/fast down/slow operation, and the industrial nature of the toggles allows me to slap a bank up or down 1-5 at a time if I wanted.

The early pre-war transformers operated in a similar stepped way and an additional range selection by tap choice (like the low volt 1033 option of 0-11v vs 5-15v throttle by using a different terminal set.

Hard to see the black box's 5 toggles. They already have a rubber toggle cover for weatherproofing and additional isolation. The "curtain" normally covers it all and moving the toggle with the cloth stretch is easy. No need to look behind the curtain, no vague feel; just don't poke Santa in the face 🎅 ... And the other tip is "Express" means express; as in high/low coarse is best done there.