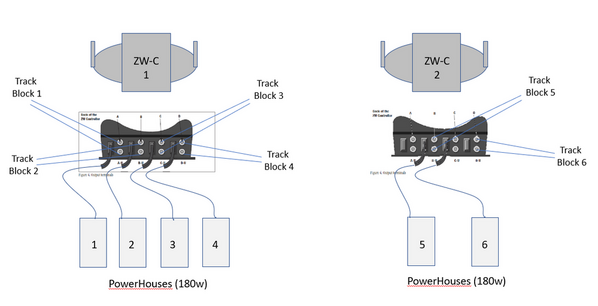

The circuit breaker on one of my 2 ZWs (new in 2004, used under 5 hours a month since) keeps tripping as soon as I power it up. I’m trying to diagnose which of the 6 blocks on the layout is causing the short circuit. Each block is powered by its own PowerHouse, same vintage. All track is FasTrack, and each adjacent piece of track in each block is wired together with soldered connections.

The short first appeared recently, after cleaning the track with CRC contact cleaner, one of the non-polar cleaners recommended in Model Railroader Hobbyist of May 2019, Publisher’s Musings. Before that there was never a problem.

All cars and locos are off the track and I’ve gone over every inch of track to make sure there is nothing to cause a obvious short.

As a first step to figure out which block is causing the short, I was thinking of turning off one PowerHouse at a time, and then powering up the ZW to see whether it still trips. Question 1: Will this damage anything?

Question 2: If the ZW does not trip with that PowerHouse turned off, does it pinpoint the problem to that block of track?

I’m sorry to ask such a naive question. I’ve not used my layout in 10 years and am amazed how much I’ve forgotten in that time, even after building the layout myself. I’d sincerely appreciate any help or direction Forum members can provide.