Chris,

3D printing can either make fantastic full-sized print or parts for kits that can be assembled at a company or home. In answer to your question, the bane of every 3D printer enthusiast: time, reliability, and cost

I work with additive manufacturing at my job and there are printers out on the market that certainly have the build-plate size to make O-gauge rolling stock. First you have to look at the type of 3D printers that you would want to use, there are many options but I'll give you the 3 most common types (definitions are for those unfamiliar with the 3D printing world):

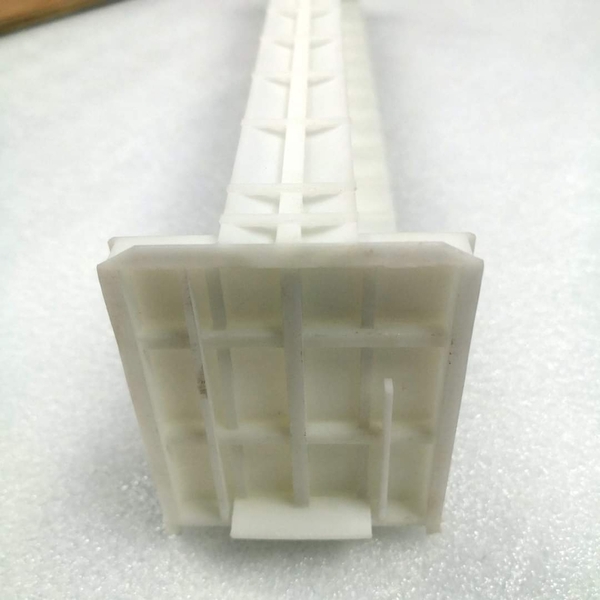

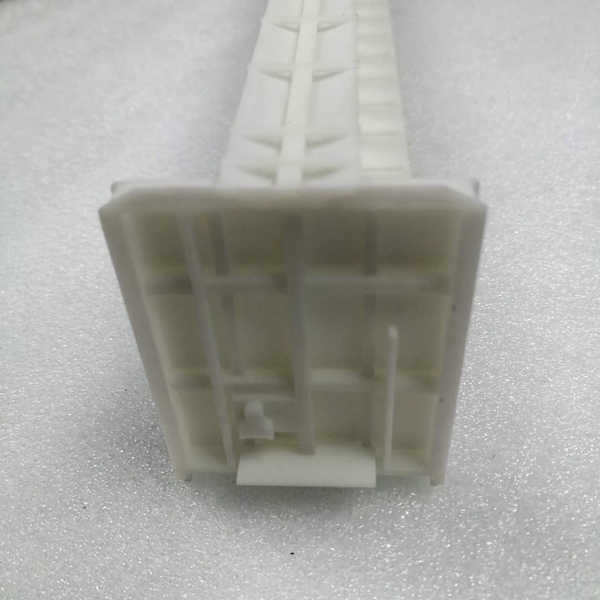

Fused Deposition Modeling (FDM): This utilizes a thermoplastic filaments which is extruded through a heat nozzle, melting and applying to the plastic layer by layer. FDM are the most common and you can get these printers at relatively low cost (anywhere from $300 an up) but you'll sacrifice detail and you will have to smooth the build since the print layers will show. They do have larger build pate printers which do not cost as much as a SLS or SLA of the same size would. I personally am a huge fan of Lulzbot as they allow the user to customize everything and anything. Not to get too off-topic but with Lulzbot I was able to configure settings and modify the extruder to 3D print metal, ceramic, and nylon. Depending upon the size, FDM can either make one large print or parts that can be assembled.

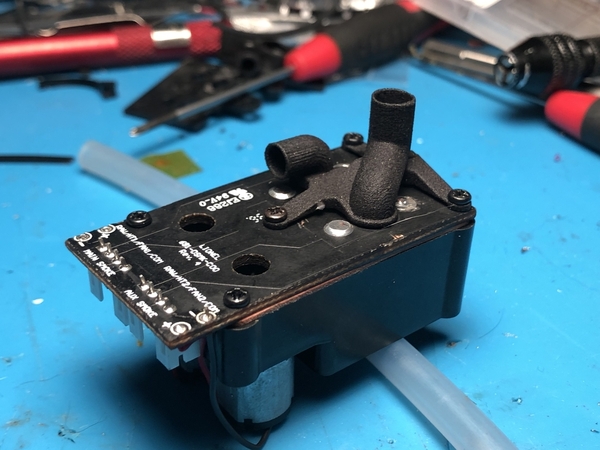

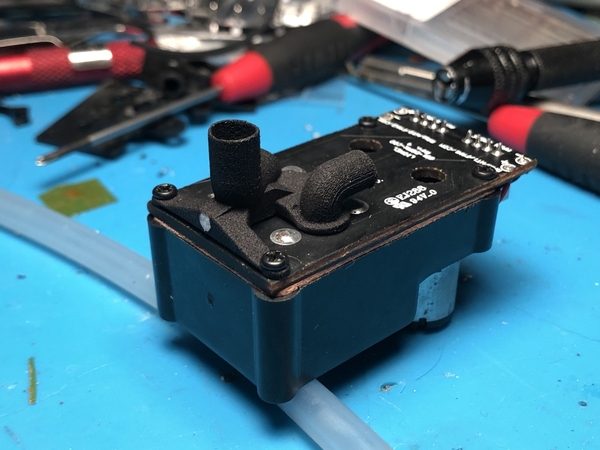

Selective Laser Sintering (SLS): A high power laser sinters small particles of polymer powder into a shape. The unfused power acts as the support (this is fantastic for complex geometries, interior details, thin wall, etc.). SLS does some amazing prints but from my experience at work, is a royal pain on the best of days. The excess plastic power can make a mess, but the good thing is it sometimes can be re-used depending on the polymer. Personal safety is essential and this I must say that the ultra-fine powder form, it is not good to breathe in (I always wore a full facemask with bayonet-plug filters and sometimes I had to wear a hazmat like suit when emptying the printer). I will admit, the results are absolutely stunning (Lisa SLS is a great printer). Like FDM, SLS can either make one large print or parts that can be assembled.

Stereolithography (SLA): Resin printers which use a laser to cure liquid resin into hardened plastic. These printers can use a very advanced range of materials and give highly detailed prototypes with smooth finish. SLA is probably the best bet for O-gauge molders as they do not require a lot of modification once you have a detailed design that you can print. A perfect example is the Liquid Crystal Magna printer. It has an approximate build plate size of 20in. x 11in. x 14in which is ideal for a one single print O-gauge freight car. However.... This unit costs ~20k USD + shipping, too expensive for the average model railroader (unless they are independently wealthy). There are other relatively inexpensive 3D printers but they have much smaller build plates and you would need to assemble a freight car in kit form (for example: Form 3L). My guess is the average person will need to print and then assemble something in O-gauge if they go the SLA route. If we are talking about a large company like Lionel or Atlas, they have the capital to invest in the larger printers and can make full-sized, SLA O-gauge models.

Going back to my original statement, time is Achilles heel of 3D printing... time, reliability, and cost

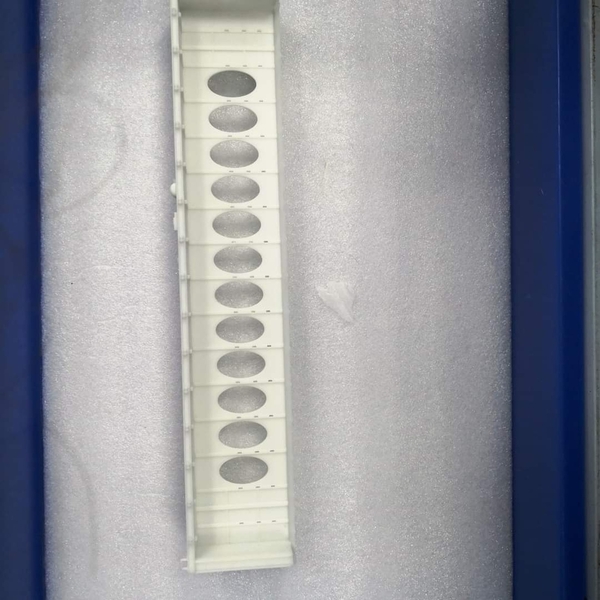

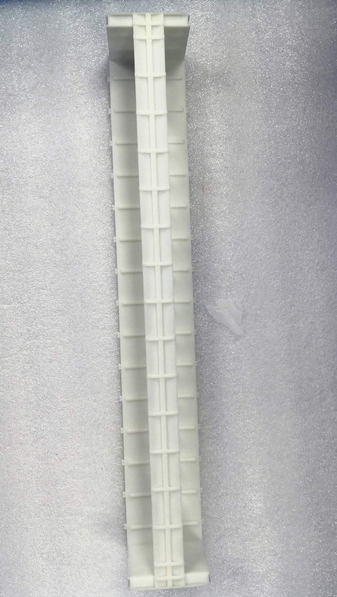

To minimize cots, maximize strength, and cut down on print time a person can play with the fill % and layer thickness of a build. Sadly, this can only do so much. I had to print out an object about the size of a Direct TV remote and even after all settings were maximized for efficacy, one print took 10 hours. 10 hours the order amount equated to one business week with all 12 SLS printers running 24/7.

Let's take your example of a gondola or hopper car. We will assume there detail inside, underneath, and on the sides of the model (equivalent to a scale Atlas model) . The more detail something has the longer it will take in the 3D printing world. To cut back on time, they could have each printer making a batch of specific parts. Again, the main shell of the freight car will take a long time to produce. Unlike Injection molding, which makes these shells in large batches, 3D printing is one printer=one shell. This is risky since the longer a print is running, the more likelihood something is to go wrong. The manufacturer then also has to determine the amount of 3D printers to match the current injection molding process. To make a very long story short, businesses care about a ROI. What is the cost of setting up new factory of 3D printers? Can it match or overtake the current manufacturing processes? How is the reliability of these printers? What is the cost for material? Can we reuse material from a bad print? How many more technicians do we need to hire to maintain, fix, and refurbish this new equipment? Etc. etc. etc...

Until 3D printing can match or overtake the current production methods for O-gauge products, I highly doubt we will see it on a mass scale.

As you know, Atlas is doing the small 3D printed accessories. From my experience, those prints take ~10-15 minutes to make and cost about $1-4 in material. After they make back the labor costs of designing these, they will have a healthy profit margin. This is the first step in the transition to O-gauge 3D manufacturing.

There might be limited run products from small mom and pop stores or individuals who have a knack for these things but I don't expect any large company to start making their detailed freight cars this way anytime soon. My guess is that they will start 3D printing the less detailed RTR sets and see how that works. Once that is mastered and is cost effective, they will move onto scale equipment with the final destination being engines.

Just my two cents.

Bryce