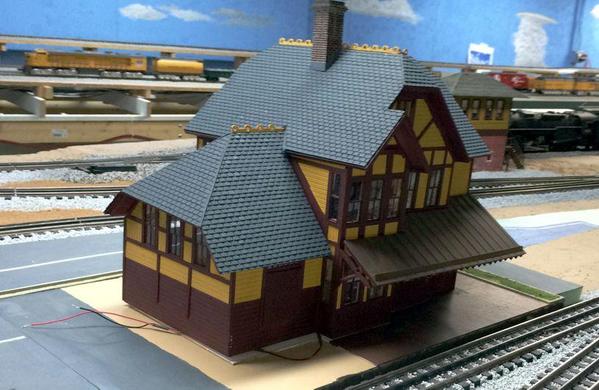

Thanks Alan! I still wonder why as my first major scratch-build project I choose a tudor-styled, Victorian, complex RR station with almost every Victorian detail. I started it almost 8 years ago. It's finally coming together.

Absolutely stunning....very beautiful scene and I love the station too! Your work is very inspiring and I am certainly enjoying this thread...![]()

Alan

Thanks Alan!

I just posted on the "For Sale Forum" an un-built Miller Engineering Parkway Diner Kit. I've had the kit since York in 2006, and with my scratch-build plans constantly changing I want to give other folks the opportunity to build this amazing model. It includes both Miller's miniature florescent light and the electro-luminescent "diner" sign. It's all photo-etched stainless steel.

I appreciate all the nice comments... it keeps me going.

The denizen of the Ravine, hereby known as Cecil the Sea Serpent, is now in a body of water. For those railfans who are old enough, there was a wonderful cartoon in the mid-1950s called Beanie and Cecil. One of the voices was Stan Freberg's, one of my favorite comic entertainers of all time. Cecil the Sea Serpent was a friendly monster like "Pete's Dragon". The kids suggested that my wife's phone fell into the ravine and landed on the back of a Lock Ness Monster. We now have one.

The above pic shows Cecil fastened to the un-wet surface. The head and tail are very over-balanced so I CA's a wooden peg into them and drilled the river bed. I used CA on the head, but used Aleens PVA white glue for the rest.

Then I mixed up the Home Depot 2-part epoxy coating and let it rip. It took about 26 ozs. of mixed material to cover the bottom. After the pour here's how it looks.

If you look closely at the right side of the back, you can see a pink iPhone stuck on his back. The kids wishes are now granted. I used the hot-air gun on the surface as bubbles rose and ended up with a very clean fill. I had to use the gun several times until it was completely clear. If bubbles are there when it sets, they're there forever.

While my dams held back the flow as designed, the river over flowed it banks and started flooding the area in the rocks. I knew these areas were low and thought the berm I built would be high enough, but the epoxy level was higher. I actually was going to wet this area anyway and it now looks really good all by itself.

It did leak out of the end and I put some tallus rock to stanch the flow a bit. It sort of worked. Again, this is not a problem. I should have used 1:48 sand bags.

It could be cured by tomorrow, and if so, I'm going to add some some motion lines around Cecil with W-S water effects. I also going to start adding foliage and greenery, and then install the bridges permanently.

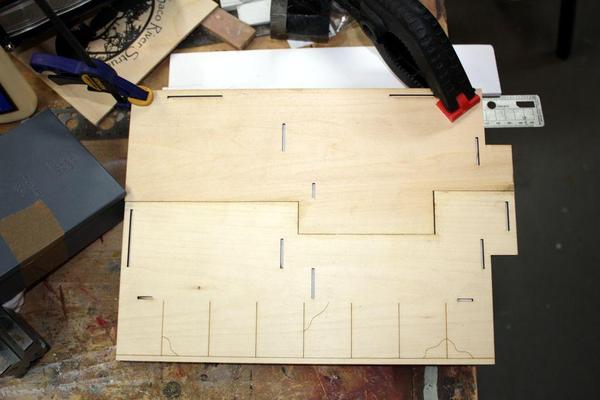

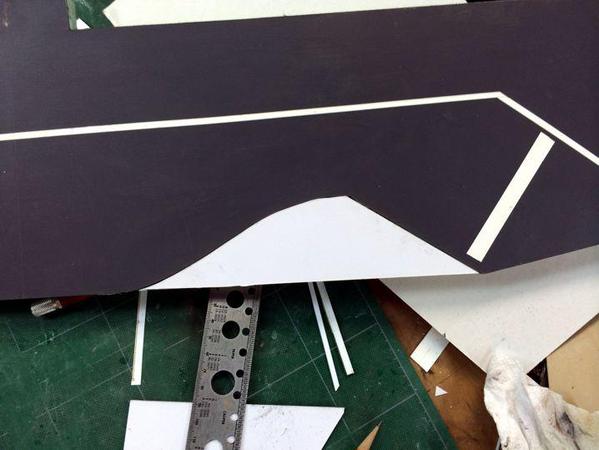

While all this is setting I went back to making roads, actually parking lots. I can't pull all the masking off the tracks until the final piece of the puzzle is in; the road to the RR station. It means one more crossing that needs plastering and painting, and more Foam that needs transition back to the bare platform. Once that's done, I can get the trains running everywhere. It's also one of the less accessible spots on the layout which is why I've let it go so long.

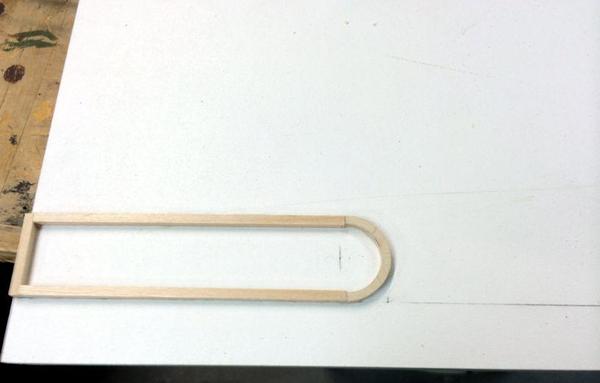

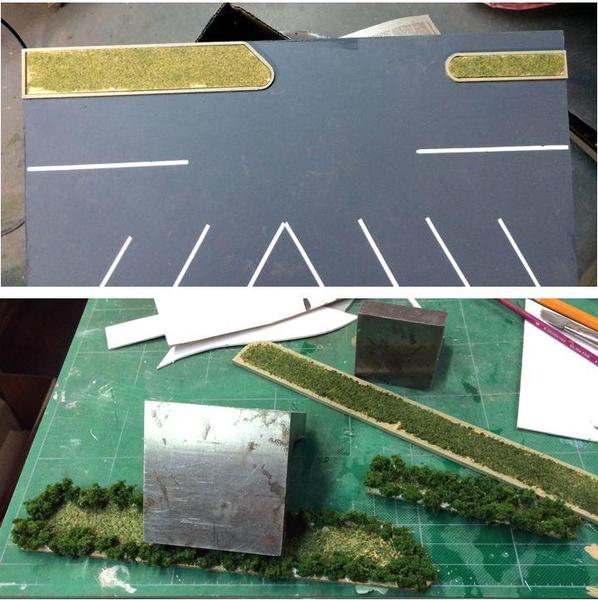

To make edging for the parking lot I decided to make a planing area framed in 1/8" curbing. The curbing is basswood and the curved curb is cut from 1/8" aircraft ply. They're glued to the parking lot surface with Aleens. I then masked the parking lines. I ran out of my thin line 3m masking so I cut strips of Tamiya masking tape.

These curbed areas will be filled with some cardboard to bring the level up to just under the curb and then landscaped with some grass, foliage and trees.

Parking lots are huge! I was only able to 7 reasonable parking spaces. Our model cars are not 1:48, but are 1:43 and therefore are just a bit bigger than they should be, making parking spaces even larger. I first was going with 2.25" between lines, but parked cars couldn't open their doors. I ended up with 2.75". My wife cracked up... She said I'm building a model with a sea serpent in it and am worried about making an "accurate" parking lot. Unfortunately, she's right. And a 7 car train station parking lot isn't very realistic. No wonder railroads got out of the passenger business.

I then mixed up some acrylic gray paint and put a brush coat on the parking lot itself AND the road connecting to it. The road has a white line down the middle.

The color mix is black, white and some yellow to warm up the gray a bit.

After looking at the road with that curved notch removed I realize how little space there is for traffic. That curve seemed like a good idea at the time. I may fill that corner in during the plastering operation.

These parts need further weathering and then gluing to the platform with the foam adhesive. The blank space to the right is where the station will lie when it's finished. The blank space to the left could be a spot for another building. I'm going to have to be careful on how much plaster I put there. Maybe I won't plaster it at all and keep it open for further real estate development. I know the zoning official...

Attachments

I think your Cecil looks convincing, and the cell phone story is great! I'm glad you folks can laugh about a lost smart phone. They aren't cheap.

Your wife's observation is good, but it is so hard to find space for a convincing parking lot. I never painted lines on my parking lots or roads. I thought they made the small area look smaller. I got away with it because I model '50s or earlier rural areas. Great job though.

Thanks Mark!

The silver lining of the cell phone story was our contract was up and we were due for an upgrade and I got a $100 rebate on my iPhone 4 towards our two new iPhone 5s's. I always make lemonade when handed a bunch of lemons. I love the 5s' camera to the point that I rarely bring the big Canon Rebel into the basement for these update photos. The 5 has what is a equivalent to a pin hole lens and has great natural depth of field which is great for close up model photography.

Today, the epoxy was rock solid, totally clear and I was ready to remove the foam dams at each end. Between the foam adhesive and some resin that leaked I needed a chisel and soft hammer to remove them. What was left behind was adhesive and some foam which I sanded off with the B & D Mouse sander.

A coating of joint compound, another quick sanding, vacuuming, and a tack rag and I was ready to put some "jungle green" fascia color on it.

Other than the slop and old newspapers on the floor, the ravine looks pretty good. When I look at it I ignore all that background noise. The camera, unfortunately, does not. The joint compound on one side was dry enough to finish, but the inside fascia was not and that will have to wait until next session. I found out—gladly—that all the spilled plaster on the floor comes off with scraping and washing. That's good since I didn't want to have to repaint the floor...yet.

While joint compound was drying I went back to work on the station area. I put a filler piece onto the road to fix that funny curve. After cutting some foam and then Bristol board I glued it all up with hot melt foam glue and Aleens. I tried it out on the layout to make sure that straightened road didn't run afoul of the adjacent track. It didn't.

This fix won't be invisible. I may use some filler to hide the seam, or I may purposefully paint it a different shade and leave it as a road patch.

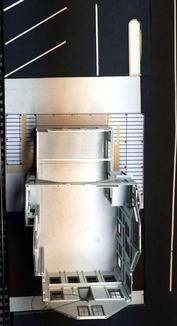

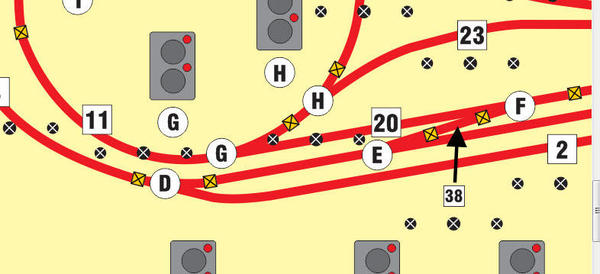

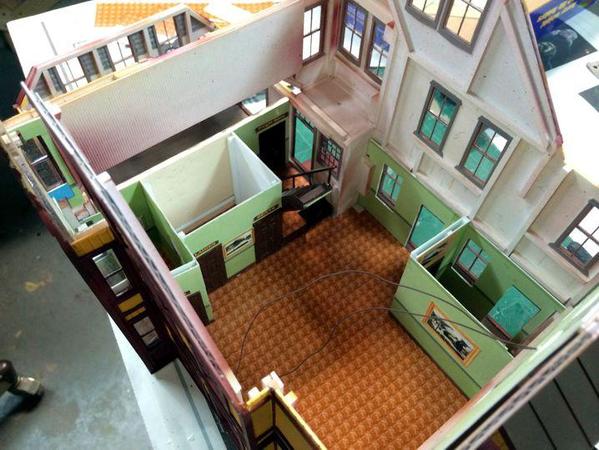

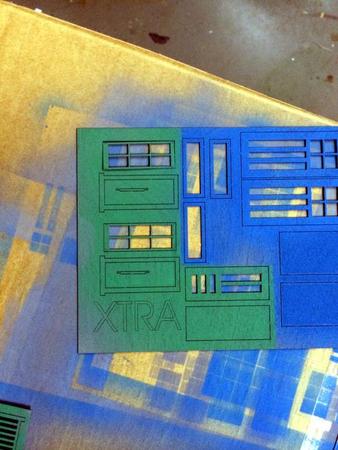

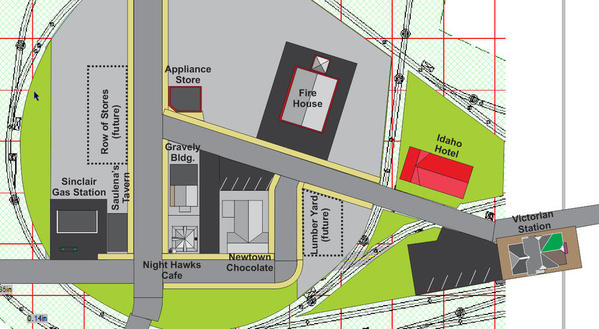

I put all the stuff back on the layout and took an overhead shot of the station area so I could do some more landscape architecture. The first thing I saw was the loading dock being too wide and extending out onto the road. I went back to Coreldraw and rectified the situation by narrowing the road side loading dock a bit.

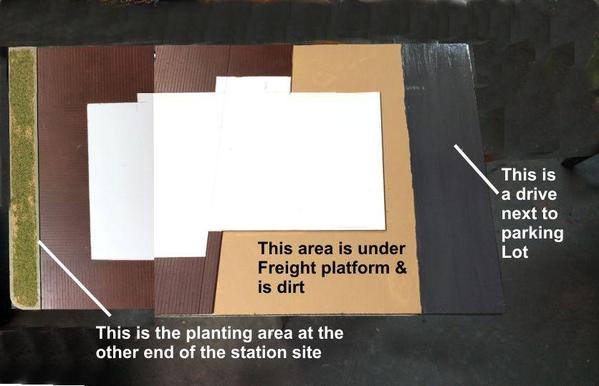

It was through this image that I decided to make the area next to the parking lot paved as a drive and make a planter on the other end. The loading dock in this pic is just the CorelDraw image laid under the station. I'm glad I did this before I spent several hours building that platform only to find that it was a quarter inch too wide.

The planters at the parking lot have thick cardboard fillers, painted earth color and with grass mixture added to the wet paint. When this was sort of dry I added bushes around the perimeter using W-S scenic glue. When this is dry, I'll install them in the curbing and add some ornamental trees. The weight is pressing down on the filler until it dries. Between the water-based latex paint, the water-based scenic cements, and the "wet" water sprayed on it to let the glue penetrate, the piece was starting to warp pretty badly. I'm hoping the the weight will help flatten it out as it dries. (I just checked... it's flat)

For the other end, I cut the entire thing out of a piece of 1/8" aircraft ply, marked where the curb would be, and then painted the interior earth color and the curb concrete color. I then was a bit more careful in gluing all the foliage to it. This one didn't warp.

This composite picture also shows the coloration of the other end of the station's baseboard.

It's the weekend so I probably won't be back in the shop until Monday. Retirement's great! My work week consists of building my model railroad. What could be better than that?

Attachments

Trainman, you are doing such an amazing job, such an inspiration (sorry if that sounds cheesy). I'll have to re-read this tomorrow when I'm not exhausted to make sure I understood everything, but I'd definitely go with the stone retaining wall.

Mike

I'll take cheesy any time over criticism... Thanks!

Today was a mixed bag. I finish sanded the repaired crossing—they're waiting for paint. I decided to add some topography next to the parking lot, and while some adhesive was drying got started building the train shelves.

The realigned crossing now has a much smoother approach than it had originally. It will look much better and operate better. I pre-taped the road from the station so I don't have to go back and grind it while installed.

I'll paint these crossings when I paint the remaining ones leading to the station.

Instead of piling up cardboard strips I decided to use some old Masonite that was laying around and build up a topographical "stair-step" to make plastering go faster. I shaped each piece to taper smaller and then beveled the edges to make the transitions even smoother.

The bevel was put on using a belt sander and the initial cuts were done with the saber saw.

The first piece was glued to the table with foam glue because what's beneath is mostly foam with a little OSB around the edges. I also wanted to strengthen this area a bit since I had already put my elbow through the foam once and didn't want to do it again. It took a lot of weight to get it to lay flat since the foam was marginally thicker than the surrounding OSB. Now that I'm going to have some contour to that wedge-shaped area, I probably won't put a building there, just landscaping.

Since the foam glues takes overnight to cure, I needed to work on something else so I got started on building the train shelves. These are not going to be your furniture quality shelves that some collectors use to line their train rooms. Nope! This is cheap, pragmatic, get-some-shelves-up-on-the-wall, down and dirty train shelves. The reason I'm digging into this now is simple. I took my T1 off the track to replace the traction tires. I didn't have a tire for this engine and had to call 3rd Rail. So where to put the engine? Nowhere, that's where! I still have four engines that aren't even unpacked yet, plus a load of passenger cars. I need a place to put trains that aren't currently on the layout. I also have too many engines parked. I would like to have one engine per siding. It makes it much easier to operate the layout. I can only manage about 12 engines on the layout at one time. I have 17. Shelves will help.

The wall isn't even sheathed. It's just open studs enclosing the space under the cellar steps. Instead of spending the time and money finishing that one part of the basement, I put a 5" strip of Masonite behind each 1 x 4 that makes up the shelf proper. The Masonite acts as a backstop to keep trains from falling through the studs. It will also effectively hide the open wall behind.

Without a table saw, I relied on the saber saw to cut the strips, using a 1 X 3 as a fence. In retrospect, I could have use my Skil Saw to cut the strips. It would have cut faster and made a straighter line. Oh well...

Anyway, to speed up setting the fence, I've made two spacer blocks (2" and 2.25") to use to offset the fence by the distance the blade is from the saber saw's edge. I use quick clamps to hold the fence in place. Since I was using Masonite scraps to make these strips, I had to set up the fence many times.

All the shelves are assembled with their Masonite backers, and I started fitting track to it. I have a lot of Atlas straight sectional tracks left over from when my railroad was essentially a display of trains on shelves in the office of our house in Germany. I also have a bunch of Ross straight tracks that can be pressed into service, so I shouldn't need to buy anything more. I'm using simple 90º steel angle brackets to secure the shelves to the studs. Don't need a stud finder here. They're staring me right in the face.

The shelves will be up on the wall probably tomorrow. Then I'll finish up the station area terrain work.

Oh... and one more thing... Remember those Grandt Line doors that I knew I had and couldn't find. That led me to make a bunch with manila file folders and styrene. Well... they finally showed up. When I was emptying the shelve unit to move it across the room in preparation for the shelves, I had a NWSL box from the sander, and it rattled. In it was all the missing parts from the Station. I'm going to use the Grandt Line parts since I want to have some doors open and they have details on both sides.

I knew that I had them, I was just unsure that they made the move. They did. There was also extra porch posts, which I had already re-bought. Oh well.

Attachments

I thought I had all the crossing problems solved, but found that freight car truck journal boxes were hitting high spots on some of the crossings that I had reworked. Now I will. The grandkids found one and I found the other. They're having an overnight and will work on the trains with me tomorrow.

The kids said if I just let them keep hitting it, it will eventually wear away enough to clear. That's not how I do things. I'll fix it.

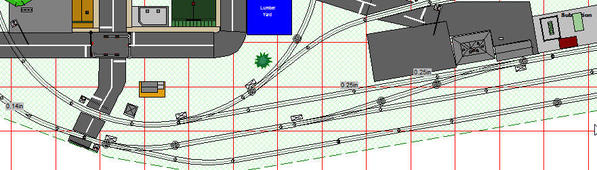

I think I figured out the Block 11/20 interaction problem. After looking at the actual track, the diagram on the control panel and the original RRTrack plan, I don't think I put an insulator between those two blocks. It's one block with two controlling DPDTs. When they're together it's no problem. When they're opposing, If one throttle's off, the voltage feeds back through the line to the off channel and energizes it. The fix. I make an insulating cut someplace to isolate them.

The Yellow squares with the X in them is the insulator. Notice that between 11 and 20 you don't see one on the diagram or track plan (two circle bulls eyes are the insulated joints). I hadn't noticed this problem before since I was usually running the entire inner loop set on one throttle and outer on another. In this one instance I was running just the inner loop and just block 11 to test the Allegheny and saw voltage on both channels. I'll double check this tomorrow and make the gap if necessary. I really don't know how this one slipped through.

I put up three train shelves today and will have the remaining two up tomorrow. The 1 X 4s I bought have a lot of twist in them. So much so that one end of the shelves tilts inwards and the other tilts out. It's actually bending the angle brackets. But the trains are falling off. I tested it.

Attachments

You show track plan and talk of isolating blocks 11/20 far as I can see the switches are the Block or am I missing something here?

I am used to Ross switches but assume the other track manufacturers have same hot rail segregation.

thanks for clarity if you can am really curious.

I look forward to your updates as I never know what you will be doing next.

hope you had a great grandkids and train day those are priceless moments.

$oo

I have Ross switches but none of my hot rails are connected together.

I wire each leg seperately.

thanks for telling me the why for.

$oo

I haven't made the repair yet. Instead the kids were here yesterday. The younger was working on a clay stone wall that will be in front of Serpent Gulch. It was over this wall that my wife lost her cell phone.

Older grandson glued the remaining three pieces of the topo stack next to the station parking lot, and then made a barren ground-covered area into a nice meadow.

He's good at this, and I don't necessarily enjoy it. Good deal!

I was putting up the train shelves. It was a great use for lots of Atlas track that I had since Germany. I used it for my train shelves there before I had a layout. I had enough to fill 4, eight foot shelves. For the last shelf I used lots of little chunks of Ross straight track that were taking up space in a box. I didn't use any of the intact 29" straights that I had since I have future use for them when the coal mine goes in.

This clearly isn't a fancy train room project. I mean the wall's not even paneled, but it is pragmatic and utilitarian. the Masonite keeps things from falling into the space under the stairs. In a different world, I might have had the basement finished before building the trains, but since this project was done as I was entering retirement, pragmatic had to lead the way.

The track doesn't have end bumpers. While I could have gone pragmatic, in this case, I'm going a little goofy; building bumpers out of Ross railroad ties, and making them sort of scale like. I'm not sure this decision is making any sense since I have so much other stuff to do, but... I like building stuff.

The bumper has 8 parts.

Ross ties are basswood. Half the cuts are done with a razor saw and miter box, the others are done on the scroll saw. After cutting I true up the edges with a sanding stick and/or the NWSL precision sander. Tight fits make gluing much easier.

Here're the assembly just hanging together. After gluing, I think I'll use some brass rod on any critical joints to make sure they stay together. Engines can roll due to non-reversible worm gear drive and traction tires, but cars are different story.

I'm not sure if this design is even prototypical, but it has to fit between the track and the edge of the shelf, especially the one with the Ross track. I extended that track a little closer to the end then the other ones.

BTW: I found Atlas track a real pain to cut. Ross track is much easier to make custom cuts, IMHO.

Since there's 5 tracks I'm going to need 10 bumpers. At 8 pieces per, I need to cut and shape 80 pieces of basswood. Like I said, this is a goofy project. I'm setting up a mass production approach, cutting the entire needed quantity of each piece in one go, and then assembling the whole lot of them. There's no rush...I may do some each day and take a break doing some plastering, landscaping or whatever.

If these work out well, I might substitute those Lionel plastic ones currently on the layout. In the engine house, the bumpers may be concrete or structural steel affairs.

Attachments

Trainman,

It must give you great joy to share your hobby with the grandkids!

I think the bumper looks good! One sees all kinds of bumpers in real life made of whatever was handy, usually rails or ties. Why not ones like your design?

Thank you so much for the ongoing documentary!!

While I really didn't want to, I got back to plastering today. I finished the last crossing next to the train station, added Sculptamold to the topo area next to the station parking lot, and modified the other crossings that were still exhibited problems. I also cut the insulating gap between blocks 20 and 11 and solved that seemingly perplexing problem. The rule is, "when you rule out all the possible causes, all that's left is the impossible ones." There's no way I built the layout with two blocks connected, but I did.

Then I went back to cutting the pieces for all those shelf bumpers.

Using the Masonite topo molds underneath really limited the amount of plaster needed to build it up, and added strength over an area that was basically paved with foam. When this dries I will put a second coat of joint compound on the crossing itself, and then paint and landscape.

I cut the gap. Immediately I had two toggles that no longer fed voltage back to a supposedly de-energized circuit. Block 20 is a pretty short block, but it's important since it lets me shut it off before that switch if a train is paused at the station.

This above took most of the afternoon. With the time I had left I did an assembly line job cutting the various pieces to make 10 bumpers. All pieces but one are used in pairs so it means 20 of each piece. My fingers got sore.

These are the cross pieces. I cut the vertical sides of the with a razor saw in a miter box that I screwed to the work surface. This makes it easier to cut things since I don't need a hand to hold the miter box from flopping around. I used a piece of styrene that was half the height of the RR ties as a stop when the saw reached the halfway point for the cross-lap joint. I then knocked out the pieces between the cuts with a very small chisel, then cleaned up the bottom with a #11 blade and finally used a flat needle file to finalize.

This next shot shows the vertical pieces that fit into the lap.

For these I used the scroll saw to do all the cuts after laying them out with pencil lines. To final finish I used a sanding stick along with that needle file. The perpendicular cut was easy since the saw's spring loaded pressure plate could press on the piece lying sideways on the saw table. But doing the longitudinal cut was much more difficult since the piece's skinny end was facing the saw blade, and it was also lying between the pressure fingers. To keep the piece from jumping up and down with the blade was entirely up to the finger pressure I could muster. And that's where the sore fingers came from.

These two piece were the most difficult cuts. The rest will be must easier.

Attachments

Plaster was still a little damp... Sculptamold dries in two-stages. The plaster part sets in about 30 minutes, but the paper fiber part takes several days to dry out depending on humidity and how thick a layer is drying. You can't sand it when it's still damp.

So I finished up the bumpers. Since these were all hand-measured and hand cut, there was a lot of variation between pieces. It's the reason that mass production always used jigs, fixtures or computer control to ensure part to part uniformity. What I had was the opposite of that.

Case in point. While the angled end of the back brace was measured as carefully as I could (I didn't make one of my detailed drawings) the notch the brace sets into was not at the correct angle, so the angled brace in about have the cases stuck out past the datum line which mated with the front frame. I glued all the angle braces up using medium CA and then marked a line that represented a true vertical.

When the difference was large like this one, I first trimmed it off with the scroll saw and then sanded both with the horizontal part against the fence on the True Sander so the angle and straight pieces were in line.

I glued everything up with Aleen's Tacky glue. The frames were clamped when they dried, but I found that clamping the total assembly tended to knock everything out line, so I just applied glued and let them sit until they dried. I then went over the joints with some thin CA to fill in any slight mismatches.

Here's one bumper in position on the shelf. I am going to glue and possible screw them down onto the shelves. I will drill through the angle brace into and through the horizontal brace right at the notch joint, and then screw them onto the shelves. This should stop the casual bump from having a car end up on the floor. If the car is shoved against the bumper with some force, it would probably break the bumper.

Here's one bumper in position on the shelf. I am going to glue and possible screw them down onto the shelves. I will drill through the angle brace into and through the horizontal brace right at the notch joint, and then screw them onto the shelves. This should stop the casual bump from having a car end up on the floor. If the car is shoved against the bumper with some force, it would probably break the bumper.

Note: the glue is still wet in this picture.

Tomorrow, back to the plastering and crossings, and then work on the station itself.

Attachments

Trainman,

The bumpers look mighty good. Your display shelves look good and are functional.

Trainman,

The bumpers look mighty good. Your display shelves look good and are functional.

Couldn't agree more, that is all you need!

Great detail. Are we going to see any articles on OGR?

We should ask Allan. He already has one draft from me.

I am really enjoying watching the progress take place. Awesome work.

I think that would be fantastic.

I may put an article together on making the bumpers. I think that would fit well with OGRR's projects.

All the bumpers are finished, touched up, and fastened to the shelves. I drilled two clearance holes on an angle pointing towards the bumper front and used some #2 self-taping screws to fasten the bumper to the shelf AFTER I liberally applied some Aleens. The screws are really only holding the bumper down until the glue dries. Once that happens you'd have to destroy them to get them off. Good!

I also started cleaning off my disgusting work bench. I didn't completely clean it... no need to go that far, but I cleared enough space to put my engine support stand and finish working on my T-1. This is my favorite engine. It is number 6100, which is the first prototype of Pennsy's T-1 4-4-4-4 duplex series. The engine is fully streamlined by Raymond Lowey (also designer of Studebaker Avanti), and was one of two demo units. 6110 had an added booster on the trailing truck. Here it is on its delivery day from Baldwin Locomotive. My uncle worked at Baldwin at that time. That engine is BIG! Notice too how closely coupled engine and tender are. There was a diaphragm that was less than foot across. Couldn't use that engine on tight curves! Also the rigid frame 4-4-4-4 actually had a fixed wheelbase of a 4-10-4, not a 4-8-4 and this was with 80 inch drivers. More reason for large curves.

Here's my engine. 3rd Rail did a splendid job on this engine, especially in the disconnected handrails, and they weren't shiny.

The engine was running awfully. It was stumbling and stalling, even on track that was cleaned, so it was time for a tune-up. The wheels and rollers were filthy, and one traction tire was torn. I thought I had traction tires for it, but couldn't find them so I contacted 3rd Rail and they sent me replacements. THANK YOU 3RD RAIL!\

The traction tires are on the last driver so they're not blocked by cross heads, but that doesn't mean it's an easy job. The main rod needs to be completely removed so it's out of the way. The side rod needs to be removed too.

Luckily, there's enough play in the that side rod so you can bend it up to get over the crank pin. It was touch and go, but it did clear. If not, either the rod would have to be removed on both ends (as it would on the real engine) or the bottom plate would have to be removed and the entire driver axle taken out. As you can see in the pic, the screw for the front part of the side road was completely blocked by the crosshead guide. The drivers would have to be rotated to bring that pin clear.

The brake shoes and hangers must also be removed to give clearance entirely around the rim to put on the traction tire. Using a small flat-bladed screw driver I was able to manhandle the tire into position. The first side took a while, the second one went much faster. Ahhh... the beauty of the learning curve.

I then finished cleaning the wheels with Xylene and re-lubricated all the moving parts. On the track the engine ran perfectly.

I also sanded all the repaired crossing and added a coat of joint compound to the last remaining one. Tomorrow that will be dry enough to sand so I'll be able to touch up and paint all the remaining white areas.

Attachments

Trainman,

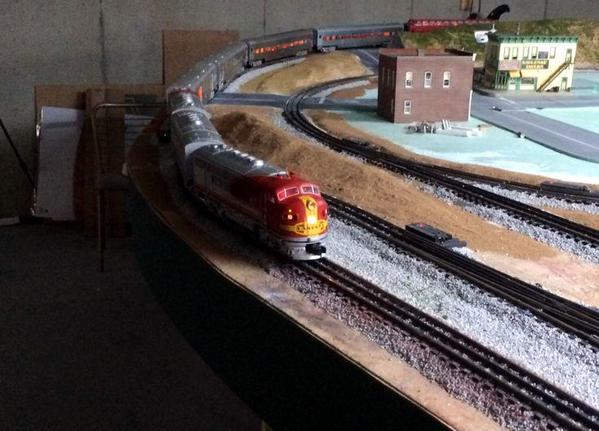

That was quite a post! The parking lot and road crossing coloring look great! It was good to see the finished shelves with some equipment on them, also. Last but not least, I really enjoyed the video of the Santa Fe passenger train. It showed your excellent track work, because you were running the passenger train at quite a clip. You may have posted video before, but I haven't gotten to it yet. I liked seeing the overall views of the layout. It is really shaping up. I was just reading about your control panel planning in the Build Thread, and there it was on the layout! I am really impressed and very grateful for the effort you have taken in showing us how you did everything and how you solved problems. You have inspired me to do likewise when I get building again. I will need a better digital camera than on my iPhone 4. My photos are too grainy.

One question from the old thread. Who makes Flexibed? I did a quick Google search, but did not turn it up. I saw the Ross Bed listed on Ross' Web site. Are the two made of the same material? Could you reiterate on why you selected it. I have always used cork in the past. Thank you so much!

As always, Thanks Mark.

Flexibed is produced by Hobby Innovations. http://www.hobbyinnovations.com/

It's their newer product. Their older product, Vinylbed, was used on the first two iterations of the layout. Flexibed is a medium density vinyl foam. It's quite flexible, absorbs sound well and glues well with Liquid Nails or other structural adhesive. You don't need to slice it to bend it around most corners. They make several thicknesses and solid sheets for yards and under switches. Vinyl bed was made out of vinyl granules and was harder to cut and form than Flexibed, which cuts easily with a utility knife.

Ross bed is a rigid urethane foam. In other words it's quite different than Flexibed. It is molded to conform to all of the Ross products. The reason I mixed the two products was the extra time it takes to fit and trim the Hobby Innovations product to fit around all the switches, but Ross bed was too expensive to do the 300+ feet of track I had so I compromised. I put the Ross product under all the switches and Flexibed under everything else. I used the thinner Flexibed product (1/4) since it conformed perfectly with Ross product so there was not height differences at the interfaces. You have to trim the Ross bed in some situations depending on what side of the switch your switch machines lies.

I'd probably go that way again if had to do it over (never... no... oh please... not that!!).

I'm using the iPhone 5s for most of the pictures and it works just fine. The movies also come from that phone. I had a 4 and the pictures weren't worth publishing. My son in law has a GoPro camera for his skiing movies. He's going to lend it to me so I can shoot engineer's point of view movies. The GoPro produces a very nice HD quality image. I have an iPhone app to control the camera from my phone while shooting. Now that all the tracks are again open, that movie should be coming along soon.

I went looking for movie editing software only to find that I already had it on my HP. Microsoft Movie Maker is packed in the machine and gives basic editing, labeling, effects to put together acceptable YouTube movies. I was able to easily combine several shots into one.

Thank you for the link to their Web site. I'll take your excellent recommendation into consideration when I build in a year or two.

Our 2 year phone contract comes due in June. The girls are still on it, and pay for their own phones etc. I'm sure the younger especially will want the latest and greatest. Her boyfriend has one. We will see then whether it is time for Mum and me to upgrade too. If not, we probably will by the time I get building again.

You need to drop (throw) you cell phone over a ravine. That will force you to upgrade. It worked for my wife. And since her phone needed replacement and we were both out of contract, I just HAD to replace mine too. It was an excellent decision.

You need to drop (throw) you cell phone over a ravine. That will force you to upgrade. It worked for my wife. And since her phone needed replacement and we were both out of contract, I just HAD to replace mine too. It was an excellent decision.

Yes, excellent reasoning! ![]()

The secret to a long marriage (today is our 46th anniversary) is she gets hers and I get mine. It usually works like this: 1 train = 2 to 3X jewelry. This formula has worked well for years.

The secret to a long marriage (today is our 46th anniversary) is she gets hers and I get mine. It usually works like this: 1 train = 2 to 3X jewelry. This formula has worked well for years.

Congratulations. What kind of train does a tennis bracelet yield?

Congratulations on your anniversary!!!!!!! ![]()

I like your math, except I think it should be the other way around 1 piece of jewelry = 2 or 3 train items of our choosing....

It's a 3:1 ratio in her favor. So a $1,500 t 3rd Rail brass one gets her a real nice one.

As far as I can tell, a reverse ratio would be proof of an alternative universe. The fact that a spouse lets a guy spend umpteen dollars on trains in itself is a good deal.

Mike,

You haven't been married long enough to know Trainman's math is correct! ![]() It will be 30 years for us this year, and I agree with Trainman. I was able to buy that N&W Y6B and the DCS because I let my wife buy a one-year old baby grand piano last summer when the piano man said her old spinnet was not worth repairing.

It will be 30 years for us this year, and I agree with Trainman. I was able to buy that N&W Y6B and the DCS because I let my wife buy a one-year old baby grand piano last summer when the piano man said her old spinnet was not worth repairing.

Just remember the formula: Happy Wife = Happy Life!

See... Mark's got it right! About 45 anniversaries ago I found out the hard way that me picking out presents and giving them to her never really worked right. It was much better to go with her and let her pick something she wanted. It was the same with me, really special stuff was often bought together, like my superb Canon image stabilized binoculars or my Meade telescope system. The agreement, as this is also important, is: No Sneaking. I don't buy stuff and sneak it into the house, and she doesn't either. You will always get caught and it ruins the whole deal. My train expenditures are out in the open. I don't hide it.

Yes, and my wife plays by those rules too. She will even show me a $5 item she picked up at the thrift store, even though she really knows I don't care that she spent that. She just wants to show off the bargain. Fortunately for me both our daughters have caught on to always bring money issues out in the open, especially the younger one.

Had some time in the shop today. First thing I did was replace the blue-white LED head and Mars lights in both A units of the Santa Fe and replaced them with some new 3mm "Warm White" LEDs. Since there were already LEDs installed, I didn't have to worry about voltage or current limiting. When this engine was built in .08, warm white LEDs weren't on the market.

The LEDs are part of a large order I made from LED/Switch for 3mm, 2mm and 1.6mm warm white LEDs that I'll use in using for all current and future building projects. After uncrating the Santa Fe, I realized that its headlights blue-white just didn't cut it.

Lionel uses a separate circuit board stuffed up in the nose that holds the head light LEDs and the two marker light green LEDs. The head lights are 3mm and the markers are something smaller, probably 1.8 or 1.6mm.

The head light uses the full-length leads bent 90º in the middle so it reaches down to the lens in the door. One leg has insulating tubing on it. The Mars light is also bent 90º, but is mounted flush with the circuit board. The board has the "+" sign printed on it, so there's no confusion as to polarity. The new bulbs are nice and bright and look terrific with the lights out. It looks so good, over time I may change out a lot of the grain-of-wheat bulbs in many of my other engines. My Atlas SD-35's LED front lamp is not working so I may change that out also. It took is a cool-white LED. When going in reverse the rear lamps do work.

The rear A unit does have a TMCC board in it so I could imagine that under digital control, that headlight would turn off when going forward. Right now, the rear headlight is on all the time.

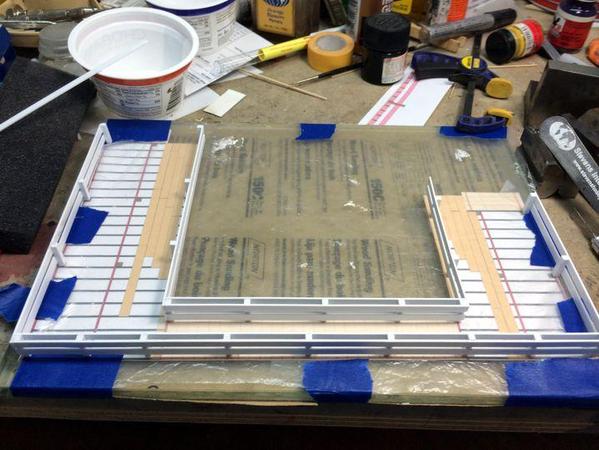

With this mod finished, I started building the loading dock for the station. This is the last major sub-assembly before painting begins.

I attached the plans directly onto a piece of plate glass, covered it with so polyfilm and built the parts directly on the plan. The 1/8" supports were cut on the Chopper II, but my fence had moved during the cutting and I had to trim and sand many of them to get them back to size. The Chopper uses a single-edge razor blade. While very thin, it is wedge-shaped and there is side thrust when it cuts stock. On thin stock the force is minuscule and doesn't affect things, but with thicker stock the side thrust is sufficient to move the fence. If it moves a small amount at each cut, it starts to stack up and piece #20 was almost a 1/16" too long.

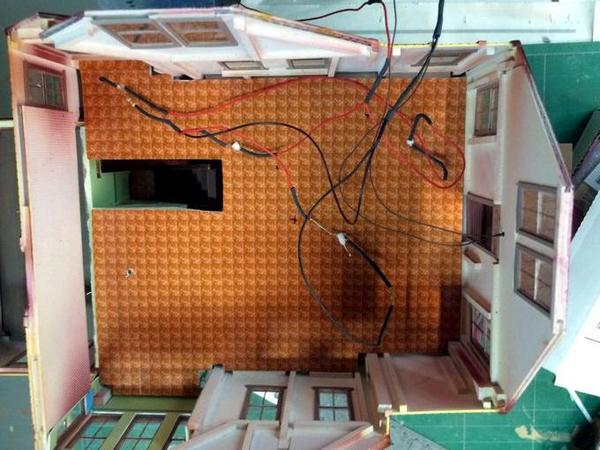

I don't know why the above picture turned itself 90º clockwise.

I'm going to use a piece of 0.020" sheet under the flooring strips. My first design used model joists set a scale 16". While this would have been very prototypical, it would be overkill in the extreme. Unless you're building a house under construction, showing joists is a waste of time. Instead, I going to lay the flooring over a sheet. In fact, I may just scribe some 0.040" sheet stock with the slats and call it a day. I'll see what I feel like. This loading dock is right up front so having individual slats with slight gaps between them would look nice...

It's fun to get back to building again. I enjoy this more than plastering and landscaping. Different strokes...

Attachments

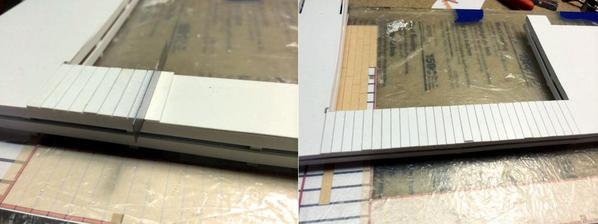

Continued work on the station's loading platform. The underframe is a little complex, but probably because I built it that way. There is an inner and outer frame. The inner frame will be glued to the station body. Both are sitting on scale 6" square timbers. I glued them together over the plans initially, but needed to be sure they fit the station as built.

Pieces of .125 X .156" stock forms the connectors between inside and outside frames.

I tried it on the station and it fit fine.

Before going further, I decided I'd better try it out on the layout to ensure that the trains don't smack into it. It's a good thing I did. The track side was about an 1/8th inch too wide and did get clipped as a train went by. I cut the double rails on the right side flush with the inside of the corner post, cleaned off the remains of the .040 X .188" stock and then re-glued the end rails to the post in their new position. This should solve the clearance problem. Trains do come very close to loading platforms.

I couldn't help myself. When I had to move the trains out of the way so I could position the station, I ended up parking them on the bridges and took a picture, just for fun.

There's still soooo much to do. I simply don't know how Patrick completed his railroad so quickly. One of these days I'll do something with the open-framed high line...

Attachments

Continued work on the station's loading platform.

I tried it on the station and it fit fine.

Before going further, I decided I'd better try it out on the layout to ensure that the trains don't smack into it. It's a good thing I did. The track side was about an 1/8th inch too wide and did get clipped as a train went by. I cut the double rails on the right side flush with the inside of the corner post, cleaned off the remains of the .040 X .188" stock and then re-glued the end rails to the post in their new position. This should solve the clearance problem. Trains do come very close to loading platforms.

I couldn't help myself. When I had to move the trains out of the way so I could position the station, I ended up parking them on the bridges and took a picture, just for fun.

There's still soooo much to do. I simply don't know how Patrick completed his railroad so quickly. One of these days I'll do something with the open-framed high line...

Having seen Patrick's layout twice in person, it is amazing what he did in such a short time. I went on back to the beginning months of his thread, and saw his layout had initially taken shape much faster than I had realized.

While not like his, yours is progressing pretty rapidly too. The test run was a good idea for the station platform,and the photo of the train on the bridge is great.

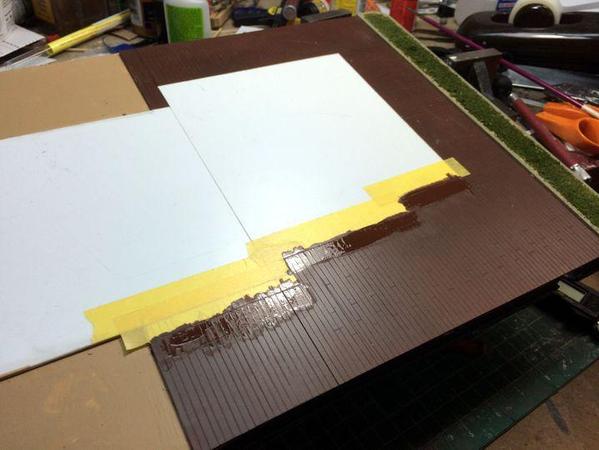

More work on the station. Working around the porch posts created complexity. I want to paint the loading dock while still separate from the station to both save masking and to do a better job on the loading dock.

I split the frame around the posts and then split the underlayment. At first (shown) I made a square hole for the posts and put a slit down the middle. I realized this would solve the problem when the flooring was glued to the framing so I opened the slit to the post width. The reason for the double-sided slats is that they were cutoffs from one of the other frames. I didn't waste anything.

With this fitted, I decided to put it back on the layout and run a train by it to check clearances. Again, I'm glad I did. The train smacked into it again. Instead of cutting more loading dock away, I simply moved the whole station away from the track. It exposed some new white plastic on the mounting plate which I re-scribed and painted.

Once that was solved on went the floor boards, starting with the narrow section.

I used a Gargraves connecting blade as a board spacer. I worked from end to the middle, but believe it or not it worked out perfectly. After this section I started on the track side. For this I had to cut more boards using the Chopper.

Here's the track side.

The boards are about 10 scale feet long so I don't know if I need to scribe joint lines in them. Right now I'm leaving them alone.

Here's the street side:

Now comes the tricky part. The dock needs to be glued in position before those last boards on the porch need to be installed. Since I want to have all the boards match, I airbrush the completed part of the dock and the loose boards at the same time. Then I install the final boards after the dock is glued in place. Getting closer and closer...

Attachments

A very impressive station, coming along well. I like the little details like the posts and gingerbread near the door, etc. Very nice

What a spectacular layout and read! It took me well over an hour to read this thread from start to finish but well worth the time.

I congratulate you on your attention to detail. I will be following this thread to see how it all turns out.

Well over an hour!! I must be a slow reader. I have been working on Trainman's L-girder thread and this one a bit at a time for weeks. I too am very impressed with what he is doing, but in how he is documenting it for all of us. What's more impressive is in a lot of cases he is learning as he goes. Thanks Trainman. There is hope yet. I am only 11 years younger than you by your statement about writing in '63.

As usual, thanks Mark and all others who read and comment. Mark's right! Many of things I'm writing about are firsts for me. All the other versions of this RR did not have scenery or scratch-built anything. All of this is new, and I'm experimenting and learning as I go... then sharing.

As I see it, there are two different kinds of folks: those who are unafraid to try new things and those that are reticent. I fall into the first type. it was why I wasn't too worried about taking a long-term assignment in Germany at age 53. I knew it would be an adventure and it was. Same goes for moving to Louisville.

I wasn't always this way. I didn't realize that I had any intellectual power until my late 20s. My school experience was average, average and more average. In my late 20s when I finally went from public school teaching to industry I found out what I had to offer. It was quite an awakening. It can happen to anyone.

I haven't stopped learning. Latest studies indicate that even in us older folks new synapses are being created and learning continues. Motor skills learning is not quite the same. In that case, most ability for new motor skills learning ends in the early 20s. That's why it's so freaking awful to take up golf in your forties. Just ask me...

Beautiful work!...and a beautiful attitude...really like your post above!

Alan

Thanks Alan!

I have several hundred build pics on my iPhone. Now that I'm retired and don't talk about "work" any more, my new "work" is the trains. I'm getting some negative feedback from my chief counsel that I should stop whipping out the iPhone and boring the bejeezus out of people giving them all the gory details about building a railroad. Most people don't care as much as the people that read this great forum. Oh well...

Excellent!

Dave

Thanks guys!

I picked up the sick Santa Fe B unit today. And guess what? It came in under estimate! Reason: They were able to track down the specific chip on the R2L2 board and replace it. It was a tiny surface-mount think about an 1/8" sq. The motor's worm gear part that runs in the bushing appeared to be over-sized and was binding in the bushing enough to over heat and put drag on the whole system upping the current. So a new motor set, rectifier and that one chip fixed it for just a bit over $100. I tried it out and it did work well and is now in the lash up with it's siblings. But... tonight it started all over again... running nicely and then current draw goes up, speed goes down to eventually stalling. This time, though, it's the A Unit, not the B that's causing the problem. I'll take that into the shop and see what's what. I'm getting tired of this engine. It's a beauty, but much too temperamental.

When I got back to the shop I put the last step on the loading dock steps and then painted it a weathered brown (a mixture of haze gray, Tamiya brown and black). It was a pain in the neck!. The paint kept clogging in the air brush. I had to completely clean it out at least four times to finish the job. I had mixed an alcohol-based acrylic (Tamiya) with a water-based one. It tends to clump and did multiple times.

I chose not to scratch the surface. A deck like this would have many coats of paint on it and not shown wood grain. I will weather it a bit with the powdered chalks. You can see the remaining slats waiting until the deck is secured.

I started masking the station. It is a slow, finicky job—as expected—and I didn't get one side down in over an hour's work.

I'm measuring the slot width with the digital calipers and then specifically trimming the tape before sticking it onto the model. It's time-consuming, but guarantees that the tape masks the intended space well.

I'm going to spray the entire model with Dulcoat before painting color to help seal any leaky areas. I'm sure I'll have to touch up some spots, but I want to minimize. In pictures I saw of the original station, they also had two-tone panels with the lower half panels the trim color on each floor. I'm not going to do that. I'll finish masking tomorrow, and hopefully be able to shoot that trim color. When that's done I do the window glazing with clear styrene, and start installing the first floor interior and then inter-floor lighting.

Spent another hour on masking and finished the track side and started on the balcony end. This one's a challenge since I have to mask areas under the balcony roof. I hadn't masked the light bulb sticking out of the balcony ceiling so I had to scrape off the first coat and use some liquid mask to keep the rest of the colors from coating it.

Sadly, I have to sell my Santa Fe (For Sale Forum) due to its having Magna Traction and being incompatible with the roofing granule ballast I'm using. The engine is like new and the problems I've been having stem from stones being picked up and getting into the drive gears. There is no permanent damage due to this on the A unit. The B unit was rebuilt because it had an out of spec worm gear on one of the motors. It runs very nicely now. I'm sorry to have to sell it. It's beautiful!, but I can't afford to have any engines that can't run on my track. Lionel is the only manufacturer still using magna traction. This engine has that PLUS traction tires.

If you know of anyone who can make a home for this beauty, please let me know.

Attachments

If you know of anyone who can make a home for this beauty, please let me know.

Sorry the Santa Fe set is affected by the roofing ballast. Who would have known about the ballast before you started. The Santa Fe Fs make a nice set. I can't say I know of anyone looking for one, but I'm sure you will find a good home for it.

Why not change the wheels and get rid of the Magna Traction?

Al

I finally got caught up on both the layout build "old and New" thread and this thread! I see it took me about 2 months to get to the point where I first picked up on this thread. It has been a great ride, and I am looking forward to more.

Have a Happy Easter!

He is Risen!

Thanks Mark! Glad you're caught up.

Al, can that be done? I don't think Lionel wheels can be changed like MTH can. Perhaps others would like to respond.

It was a beautiful Spring day today so I WAS NOT IN THE BASEMENT. Instead we took a 3 mile walk in the beautiful Bernheim Forrest and Arboretum. When we got back I was playing on the computer and doing a color study for the station. I've decided to paint the lower third of the first floor exterior walls with the darker trim color. This appears to be normal and it keeps the grime caused by passing trains being less obvious.

Looks "railroady" enough, don't you think?

Attachments

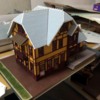

Now that you've seen the CGI version, on Easter Sunday I was able to finish the masking, take it outside in perfect weather and shoot the whole thing with Dullcoat, and then shoot the Tuscan red for the trim.

I use Polyscale water-based color so I could air brush it inside. I also fastened the doors, shed supports and shed roofs (underside) to masking tape and sprayed them too. Pre-spraying with Dullcoat really sealed the mask and I had very few leakers which is amazing considering the amount of separate pieces of masking tape this thing required.

In the next picture you also see the balcony roof painted an aged iron color that I concocted. This was shot today. The color is brown, black, yellow and red in some ratio which I could never duplicate.

Removing the tape was much less onerous than I anticipated. I used a #11 blade pointy end to just pick the tape up from the edge and then used a good pair of tweezers to grab and pull it off. In some cases it did pick some yellow, but some touching up fixed that. I also has some wear on the tuscan red when I was laying it on the workbench to pull the tape from the other side. Touch up fixed that too.

Here's the whole deal just stuck together to see how it looks.

I have to airbrush the roof edges with tuscan and then shoot the roof with a dark gray I bought today. I will do some light weathering on all the walkways and probably dust the lower tuscan panels to simulate the spray that would be thrown up by passing trains. Next comes glazing and the interior including the lighting scheme and this baby's done. As George Peppard used to say in the "A Team" "It's great to see a plan come together." It's one heck of a building.

Attachments

Beautiful looking building.

It turned out great!

Is that a lazy Susan you have the building on when painting? If so, that's a great idea!

Thanks Mark!

Yes! That's a lazy susan with a circle of corrugated cardboard on top. I've been using it for a long time to spray anything from spray glue to paint. It's much easier to rotate the model than walk around it. It's also good when I'm shooting outside. I stand upwind of the breeze and just rotate the table.

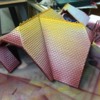

Today I had a short session, but made progress. Started painting the roofs with the edge trim and the top gingerbread. I've chosen to paint the eaves trim in Tuscan and the peak details in the yellow. I didn't think the Tuscan would stand out on the peak.

While that was drying I started glazing windows. I'm using 0.010" Evergreen clear styrene instead of acetate. When glazing Grandt Line styrene parts it makes sense to use a material that reacts with plastic cement. I measure the inside frame dimension with a divider, cut one piece with a razor blade and straight edge to check it. If this fits correctly, I then set up the Duplicutter to cut the number of pieces at that size. If the frames were wood or card stock, it wouldn't matter whether you use styrene or acetate, since plastic cement doesn't work with those frame materials. You'd have to use a PVA cement such as RC aircraft canopy adhesive and in that case, I might go with acetate.

There's nothing worse than having glazing pop out and fall into the building. It's often impossible to get in there and re-install the glass. I know... it's already happened to my Idaho Hotel. Bar Mills models uses a pre-applied pressure-sensitive adhesive on it's window frames. This is supposed to hold permanently. It doesn't always work that way. It can dry out and lose its stickiness.

These are double hung windows so the top frame sticks out beyond the bottom so you need two pieces of glazing and they're not the same size. The top one is one frame thickness shorter than the bottom. Remember: we're looking at the back of the window. I install the recessed part first and then the piece that overlaps.

I attempted to glue in the first piece using the solvent cement with a small artist's brush. I promptly got glue on the glazing. I then switched to G-S Hypo-cement (available at MicroMark). It's a plastic glue that comes in a tube with a needle applicator. It works great! I didn't mess up a single pane and I'm done the big windows.

Tomorrow I'll finish glazing, paint the roof and start laying in the interior and lighting.

Attachments

Finished all the glazing. I found some extra medium-sized Grandt Line windows that didn't get used. It gave me an idea. I had to replace two mullions that were missing in the station's windows. One was in the same size frame, while the other was a bigger window. So I painted the mullions in the extra window and after putting in the "glass" carefully cut out and glued the mullion directly to the styrene window. It worked well and now all the mullions are in place. For the larger window, I had to piece two mullion pieces together. Gluing the windows also stabilized all the other window mullions, many of which were repaired as least once.

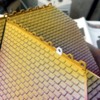

I returned to the roofs and started masking them for the major painting. One of the gingerbread peak details had broken. I had kept extra pieces just for this eventuality. I cut the broken one out, filed and sanded the opening so the new piece fit correctly, glued in the replacement.

With that in place, I used 6mm Tamiya masking tape and masked all the roof trim. After I do the grey painting, I'll go back and paint the repaired peak detail.

I didn't get a chance to mask the freight house roof yet. I do that first thing tomorrow, then paint. While the paint's drying I'll get back to installing the interior. Fun!

Attachments

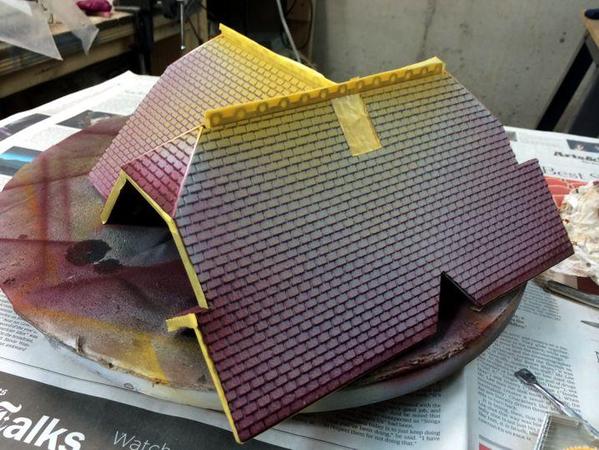

Sprayed the roof and started installing the interior.

Roof painting was nominal.

The decision to have the peak trim yellow was a good one. The contrast really makes it stand out. Again this is just a trial fit. I'm thinking to use rare earth magnets to hold it on when its time. The Vallejo black gray was a good color for the slate. I'm now going to randomly pick out shingles to lighten/darken/ with slight color variations. The chimney will then go on with some simulated counter-flashing on the lower edge.

I made a template to cut out the flooring print. I started with tracing the exterior profile then kept subtracting material until it conformed to the inside. Once I had what I wanted, I traced it onto the flooring, cut the flooring, installed it and held it with Krylon spray adhesive.

The fit was pretty good. I also cut and fit an elevated floor for the freight room, and painted it loading dock color.

I immediately started installing the partitions and interior wall panels. It went together reasonably well, but I've learned a powerful lesson.

IF YOU WANT TO INSTALL INTERIOR WALLS, BUILD THE WALLS WITH THE INTERIOR PIECES AT THE TIME OF CONSTRUCTION. It's the only way you can guarantee that everything will line up and more importantly, the interior walls actually cover the entire interior. Mine actually doesn't.

The biggest trouble areas are the fat 1/4" corner braces that were holding the building together. If I was to double up the walls at construction, I would have not used such large material, and I could have nicely boxed in all the windows. No one is going to see this stuff, but I know it's there.

In one area, the window cut-outs were wrong with the top cut being about 1/8" too low and was showing in the window. I had already glued this wall in and already had the station master's office glued to it when I realized this problem. I chose to cut the extra material off using the Xacto with #11 blade. This workrd, but my hand jerked and I blew the stair banister right off. I attempted to re-glue it with CA, but it wasn't going so well so I'm leaving it until tomorrow. I'm using RC 560 canopy adhesive to glue the Bristol board to the styrene. It works.

I'm going to use the floor template to cut the 2nd story floor pieces. It will be two layers separated by spacers so I can run all the wiring through the flooring and down through the bathrooms through the base. There will be two LEDs for the main floor and one 1.6 MM in the hole over the back porch. Those puppies are bright and the interior will be quite visible.

Attachments

Fabulous!! The yellow for the gingerbread looks good, and the roof does look like slate. It will be even better once you color some of the slate shingles. I agree the magnets would be good to hold the roof on. Are you going to make the second floor interior removable as well to be able to view the first floor interior?

As usual, thanks Mark!

At the moment, I'm leaning in the direction of not making the second floor removable. That being said, I can imagine where it would be advantageous to be able to remove it to make repairs to the first floor. There will be wiring extending from the ceiling down through the bathrooms on the first floor and that would make removable more of an engineering project than I care about right now. So let's say that it will be able to be removed, but not for display purposes. Where the station is located makes taking it apart to show folks not so easy.

Trainman,

Good point, I hadn't thought about the wiring because I never lit any of my buildings. Also, since the station looks to be good enough to take to shows, that is not your intent. It is to be a completed and useful station on your layout. I have never taken any of my models to shows, while I have posted a few pictures on Internet forums. I think we have the same idea, our modeling is for our own enjoyment and that of our friends. Our intent is not to show off or try to win awards, although I have no problem with those who like to do that. I am always impressed and grateful to see fine modeling at a show or contest.

I have thought about showing this model. There's an IPMS contest here on May 17 where I'm going to display the Missouri. I've also thought about showing this since it will be modular and not permanently fastened to the layout. I don't think many folks enter structures so it may be an "easy win"... famous last words. I do like the adulation though which is one reason I'm so diligent about posting everything...at least that's how my wife sees it.

Amazing work!

Since I've been running through the Woodlands Scenics Scenery Cement like it was water — water that cost over 8 bucks a bottle that is — I decided to ask my local hobby shop owner if there was a better deal if I ordered in bulk. Too bad that Costco doesn't sell Woodland Scenics products. He came in in the mid 6s which worked for me and I bought 10 bottles. Even after the ballasting is done, I will still need lots of this stuff for general ground cover gluing, and there's a lot of ground to cover.

try buying untinted paint at HD. (get a few of the sample cans to see what works)my memory says it is a flat light tint base.

This is more or less a matt medium.

also the flat modpodge at michaels will do the trick.

as much as I am a fan of woodland Scenics everything but the ground foam and kits can be found elsewhere for less money.

Using untinted base for scenery cement sounds like a neat solution. It's not too late for me to try since I have almost a half of the layout to landscape and scenic. Most home paints are latex based and dry to a rubbery consistency. Scenic cement I believe is really a thinned white glue with is Polyvinyl Acetate and many "Latex" paint formulas have similar chemistry. BTW: there's no "latex rubber" in latex paint. They're often vinyl based like the glues. Therefore, the base should be an economical way to go.

Now onto today's work effort.

I finished up the interior walls by piecing in little strips of wall paper for the corners and around those oversized 1/4" corner braces. I then added baseboards and a piece in the back hallway.

I was going to scratch-build a roll-top desk, but then found that I had some plastic furniture bought years ago at York which included a drop front secretary desk. That will work! I installed some of the furniture and am ready to paint some figures to take their places in the waiting room.

I struggled mightily to re-install the banister on the stairs, but finally got it. The banister was originally butt-glued to the vertical supports, which were very small styrene strips. Once I had to re-glue it, it was almost impossible especially since the piece was now painted. It wasn't the first time it had broken off so there was some old CA on there also. It was also an awkward location in that hallway.

After trying about a half-dozen times I realized that I needed to do something different. I drilled holes large enough to contain the verticals. When the holes were filled with CA, I had a fighting chance to get the banister to align and then settle into the glue. It worked! Not right away. I wasn't very steady and it was very frustrating, but it's not patience that I have, it's raw determination. Once it set up, I went back and touched up the paint that got damaged from messing around so much.

As I noted on yesterdays post, but it bears repeating, it would have been much easier and with better outcomes if I built the interior and exterior walls together while still in the flat. If I am to do any more buildings with detailed interiors, that's the approach I'm going to use.

"Good judgement is the result of experience, which is the result of bad judgement!"

Next work session: Folks, lighting and second floor. If I get a chance, do the roof shingle painting.

Attachments

As I noted on yesterdays post, but it bears repeating, it would have been much easier and with better outcomes if I built the interior and exterior walls together while still in the flat. If I am to do any more buildings with detailed interiors, that's the approach I'm going to use.

"Good judgement is the result of experience, which is the result of bad judgement!"

The fact that you did most of the interior after the building was put together is amazing! I guess doing it the way you did just improved your skills.

I am in awe of your work, and yes a lot of it is patience and mostly perseverance. I know.

Thanks for finding the silver lining.

Good judgement is the result of experience, which is the result of bad judgement. I live by that aphorism.

I fitted the second floor (1st story ceiling?) and then installed the LEDs. They're quite bright, but that's okay since people will be several feet away from the model and this will help them see inside.

I also spent time painting and installing the figures into the station.

To fit the floor I first cut apart the floor plan drawing and used it as a starting point. I then kept trimming until it just dropped in.

When it seemed right, I transferred the outline to some 3/16" foam core which would make the floor. This then needed some more trimming until it dropped in and settled onto the partition walls and the side brackets.

The main adjustment was around the stairwell. While it fits snugly and you have to kind of pop it loose to get it out, it does lay flat and will not have to be glued.

After fitting, I removed the floor, sprayed it and the flooring print with Krylon Spray Adhesive and then glued them together. I trimmed around the edges with the Xacto.

I then started to install the LEDs. In the main room I'm using the 3mm warm whites, and for the office and over the back porch door, I'm using the 1.6mm warm whites. I wired them in series-pairs with pair having a 330 ohm current limiting resistor.

I wired the 1.6mm's and then tested them with my 12VDC source and they worked fine. Then I hooked up the 3mm pairs and tied their two leads into the mains in parallel and tried it again. The 3mm got bright, greenish and then went PSSFFTT! Gone! In my haste to make light I forgot to install the current limiting resistor. I removed the blown ones, installed two new ones and this time wired them correctly.

The LEDs are secured to the foam core with a blob of Aleen's Tacky Glue. All leads are protected with shrink tubing. As I noted when wiring the control panel, the Radio Shack Shrink Tubing heat gun really comes in handy when wanting to shrink tubing in confined or delicate spaces.

Here's the lighting from above.

And here's the lighting from below.

And here it is with the lights off.

After I took the lighting pictures I glued the waiting room benches along with some patrons. In this case I used the Formula 560 Canopy Glue which is strong and dries clear.

I'm not sure what I want to do with the second floor. I may just put some light blocks in it and leave it in the dark. I chose not to make a double-deck floor and bury the wiring within. I thought it was overkill. The light over the second floor balcony is an incandescent grain of rice bulb that was installed 8 years ago before warm white LEDs were on the market. It works okay on 12 VDC. I'm glad that chose LEDs since they'll last longer than I will and produce no heat.

Attachments

Like building real houses, the finishing details and punch list items on the model seem to take too long.

I added the walls to the second floor, added "liquid electrical tape" to the tops of the LEDs so their light wouldn't leak into the second story since I decided I want that dark.

I traced the 2nd floor onto some fresh foam core and cut that out to be the attic floor. After minor trimming, it fits snugly between the walls and won't need adhesive.

I then built some partition walls to act as light blocks for the 2nd story. For the cross-wise on I papered the walls with the same material I used on the first floor. But when I decided to not illuminate the second floor, I covered the longitudinal pieces with black construction paper.

I also covered the attic floor with black paper on both sides so it won't reflect any light. I put some trim wood around the upper portion of the stair well since you could see it from the back door side. I think that's more AMS* coming out.

*Advanced Modeler's Syndrome

What's with the image engine on this site. It turned that picture upside down. Oh well... Not seen in the above is some more Bristol Board to fully block light from the waiting room from leaking into the freight room area which I want to remain dark.

I decided I better do another roof fitting and promptly broke off the small roof appendage on the back door side. It no longer fit properly when all the interior walls were in place. I proceeded to cut this roof down so it fits and will add it at the end of construction.

I was going to add all the doors and then realized they didn't have any handles. I was sure I had a small bag of door knob castings from Beaver Valley. For the life of me I couldn't find them, but I did find some different styled ones. I measured what was the nominal size of the little cast pins and came up with .015", I measured the spacing with a divider and noted the location 30 scale inches from the bottom. One pin fit, the other didn't. These white metal castings are not precise.

I used a bigger drill and made the holes .020", dropped three on the floor and had to use the dust brush to find them and finally got them glued in with thin CA. After the picture was taken I painted them a bronze color. Looking at the doors, they probably need some touch up paint as well.

Tomorrow all the doors will get glued in and then I'll start working on getting the shed roofs in place.

Attachments

Shed roofs are in! Roof detail painting begun, and re-glued two windows that I knocked out.

Because of the way the shed roofs are fit to the diagonal braces, you can't simply glue the braces to the roof and then glue the whole thing to the building. The roof rafters rest on a longitudinal purlin and the purlin fits into a notch on the brace. It only contacts the brace at that point so there's nothing to really glue to.

I held the roof to the building at the angle it should lie and then held the brace up to the roof and marked the location of the brace on the building wall. I then scraped the paint off the appropriate wall areas. I had made a design error when originally building the walls. I had the second story bump-out over the rear porch door moved to the left one wall timber. This occluded the very corner that the brace was to be fastened so I had to add another plastic strip adjacent to the corner as an attachment point for the brace.

Here're the three mounting points on the street-side shed roof. I did this roof first since it was the easier of the two having three same-sized braces.

I then carefully glued the three brackets to the wall in their specific locations and aligned them to each other. I then tried to fit the roof in place and something wasn't right. There was no place for the roof purlin to rest on the brace. That's because I glued the wrong leg of the brace to the wall. Whoops!

Luckily, the glue hadn't really set so I quickly ripped them all off, sanded the paint on the correct mount side, and re-glued them to the wall. Whew! Close call.

Here they are mounted wrongly.

Here's the roof in place.

There was a lot of touch-up painting to do, but the end result was pretty good.

I then worked on the track side. This side was much, much more difficult for several reasons not withstanding that the various bump-outs are not absolutely square—although I really tried to glue the building up square, but there were too many moving parts.

I had to add material on the rear mounting edge and then sand these additions to tapers so they more closely matched the wall's contour. I then held and marked the right-hand bracket (the longest one) in place as before, and marked its location. I scraped its contact area free of paint and glued it in place. This allowed me to rest the roof on this bracket so I could position the next smaller one. I repeated this four times until the brackets were fixed. Even so, the left-hand bracket didn't line up too well with the purlin, but at this point, it was going to be what it was going to be.

While messing around with the fitting my finger put pressure on a window and POP, the glazing dropped inside the building.

This was exactly the reason why I didn't want to glue the 2nd floor into the building. Even so, getting the floor out was complicated by the second story wall panels bearing down on the floor and holding it place. But I did get it out without damage. Here's where the window pane was lying.

I also knocked out another small window on the left end that I was able to re-glue at the same time. I buttoned everything back together.

I added some paper counter-flashing at the base of the chimney and am getting ready to glue it in place. I also started detail painting the "slate" roof to pick out individual shingles and painting them different shades of gray to make it more natural. I'll finish that tomorrow and then do some mild weathering.

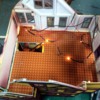

I couldn't help myself... and placed the almost-finished station back on the layout for some progress shots.

We're getting really close now. Tomorrow I'll put on the loading dock, do some weathering, add some exterior accessories (and two downspouts) and folks, and mount it to its base plate and drop it onto the layout. At that point I'm going to start wiring up some DC to get this building illuminated.

Attachments

Looking very good!

Trainman,

The station looks great!! So I am not the only one who knowing parts are not symmetrical, still clues them in backwards, up side down, backwards, what have you. ![]()

It has been a great ride, following the construction of the station. Looking forward to the absolute finished product and then moving on to one of you other thousand projects on the layout.

Thanks Guys! It's always been my philosophy to include the good, bad and very ugly. I'm learning as I go.

My lessons learned so far are:

- Use SketchUp to build a three dimensional drawing of the actual project and then use the actual roof areas to make the roof patterns. I'm doing this for the plan of the current house we live in.

- Build said roofs directly on the building to assure they're aligned. Hip roofs in general are more complicated to build and layout.

- Build the full wall thickness as part of the wall building process. This would really help to make nice looking interior window-well profiles which this building does not have.

- Work out track clearances during the design phase. I almost had a heart attack today before I actually placed the model on the layout, that the shed roof overhangs would be hit by trains. They were not, but that was not due to design, it was due to dumb luck.

- Don't put on a base plate AND then add a base plate on the mounting board. This double base plate is an added complication I didn't need. Having a base plate on the building made laying in the interior easier and stabilized the structure.

- Use copper foil tape for internal lighting wires.

- I'm sure I'll come up with a #7.

It is a beautiful structure. I like the aged copper appearance of the downspouts. You are right, the LEDs sure beat the grain of wheat bulbs.

I'll say a shot in the arm. You should feel confident building any structure you have planned for the layout.

Thank you again for sharing your journey in word and pictures.

You are unbelievably talented. What a gorgeous structure.

I really appreciate that all the forum folks appreciate these efforts. I feel exactly the same way about other's projects. It's a great community of which we're all a part.

The grandsons were here today. I had younger one make the concrete bumpers for the parking lot and we installed them together. Then we did a mild weathering job on the station. I don't think we ruined it. I used Dr. Brown's weathering powders. For the roof it was a mixture of white and dirty brown, and then some weathered black. For the loading dock we used dirty brown and the wooden ground-level deck used brown. For the shed roofs we used some rust red, rust brown and brown. I may tone the red down some more tomorrow. We added two mail boxes, a phone booth and a fire plug. Tomorrow we'll install some crates, pallets, drums, etc and a couple of folks on the outside, and then IT WILL BE DONE.

Attachments

Trainman,

No, you didn't ruin it by any means. I am in agreement this light weathering job makes it look even better. I am glad your grandsons are nearby and can help you. That will be time they remember their whole lives.

Thanks Mark! We've been in L'ville for almost five years and have seen tremendous changes in the boys. The young one was just five when we started working on the basement. Now he's going to be 10, is a computer wiz, does nice work and follows instructions well.

The older one is going to be 13! He's an excellent model maker now and is very creative. Both really appreciate what we've done. They treat stuff really well. I never have to worry that they'll do something dumb. It all started when the old one was 1 year old and he'd sit on my lap while I ran the MS Train Simulator on my laptop. I showed him how to blow the horn at grade crossings.

I bought them the "I Love Toy Trains" videos and they'd watch them over and over for hours. When the older one was two or three, and living in CA, when we visit I'd take him to places where we could watch trains, and took him to the California State RR Museum in Sacramento.

In other words, this has been a carefully orchestrated plan from the get go, like "The Boys from Brazil" only not so sinister.