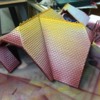

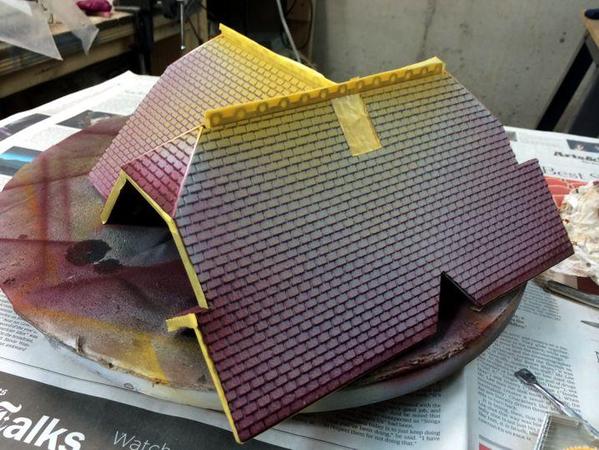

Shed roofs are in! Roof detail painting begun, and re-glued two windows that I knocked out.

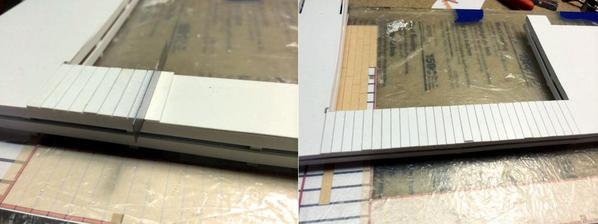

Because of the way the shed roofs are fit to the diagonal braces, you can't simply glue the braces to the roof and then glue the whole thing to the building. The roof rafters rest on a longitudinal purlin and the purlin fits into a notch on the brace. It only contacts the brace at that point so there's nothing to really glue to.

I held the roof to the building at the angle it should lie and then held the brace up to the roof and marked the location of the brace on the building wall. I then scraped the paint off the appropriate wall areas. I had made a design error when originally building the walls. I had the second story bump-out over the rear porch door moved to the left one wall timber. This occluded the very corner that the brace was to be fastened so I had to add another plastic strip adjacent to the corner as an attachment point for the brace.

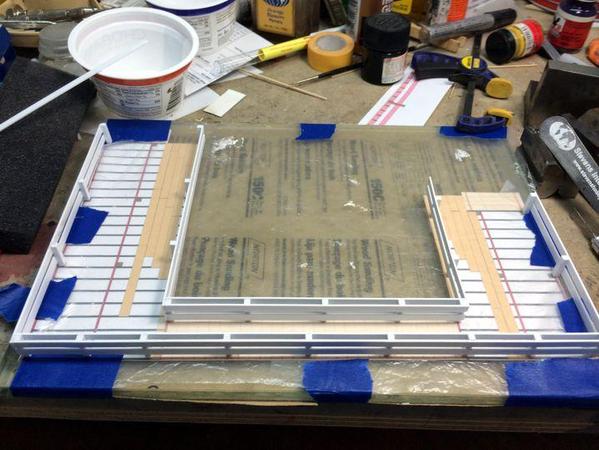

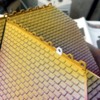

Here're the three mounting points on the street-side shed roof. I did this roof first since it was the easier of the two having three same-sized braces.

I then carefully glued the three brackets to the wall in their specific locations and aligned them to each other. I then tried to fit the roof in place and something wasn't right. There was no place for the roof purlin to rest on the brace. That's because I glued the wrong leg of the brace to the wall. Whoops!

Luckily, the glue hadn't really set so I quickly ripped them all off, sanded the paint on the correct mount side, and re-glued them to the wall. Whew! Close call.

Here they are mounted wrongly.

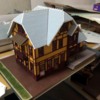

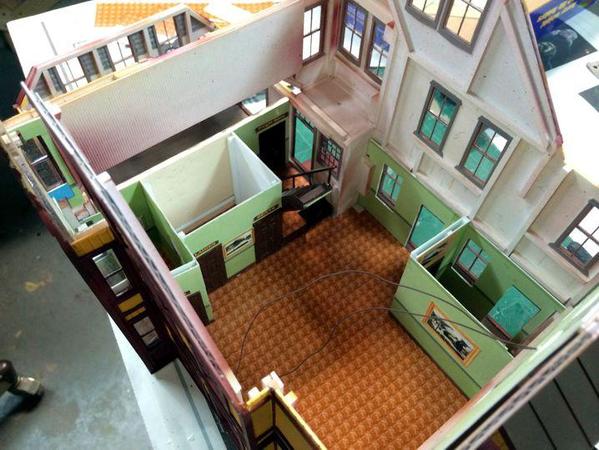

Here's the roof in place.

There was a lot of touch-up painting to do, but the end result was pretty good.

I then worked on the track side. This side was much, much more difficult for several reasons not withstanding that the various bump-outs are not absolutely square—although I really tried to glue the building up square, but there were too many moving parts.

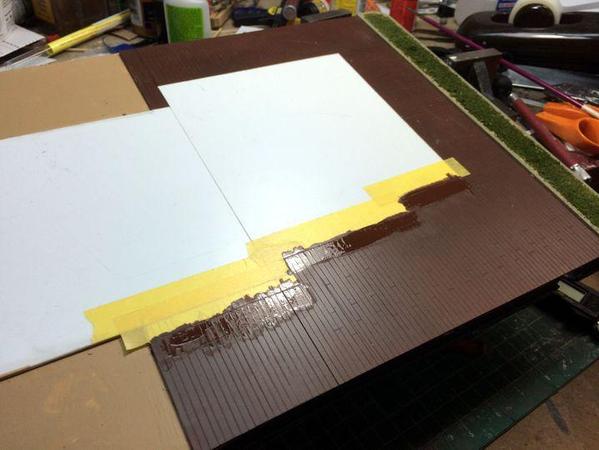

I had to add material on the rear mounting edge and then sand these additions to tapers so they more closely matched the wall's contour. I then held and marked the right-hand bracket (the longest one) in place as before, and marked its location. I scraped its contact area free of paint and glued it in place. This allowed me to rest the roof on this bracket so I could position the next smaller one. I repeated this four times until the brackets were fixed. Even so, the left-hand bracket didn't line up too well with the purlin, but at this point, it was going to be what it was going to be.

While messing around with the fitting my finger put pressure on a window and POP, the glazing dropped inside the building.

This was exactly the reason why I didn't want to glue the 2nd floor into the building. Even so, getting the floor out was complicated by the second story wall panels bearing down on the floor and holding it place. But I did get it out without damage. Here's where the window pane was lying.

I also knocked out another small window on the left end that I was able to re-glue at the same time. I buttoned everything back together.

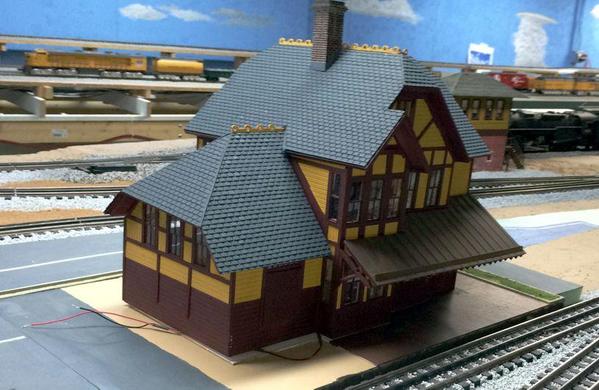

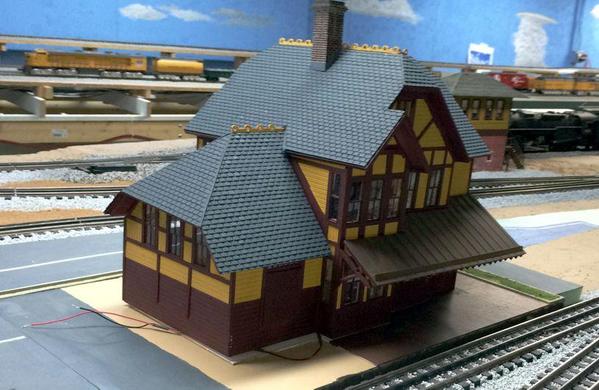

I added some paper counter-flashing at the base of the chimney and am getting ready to glue it in place. I also started detail painting the "slate" roof to pick out individual shingles and painting them different shades of gray to make it more natural. I'll finish that tomorrow and then do some mild weathering.

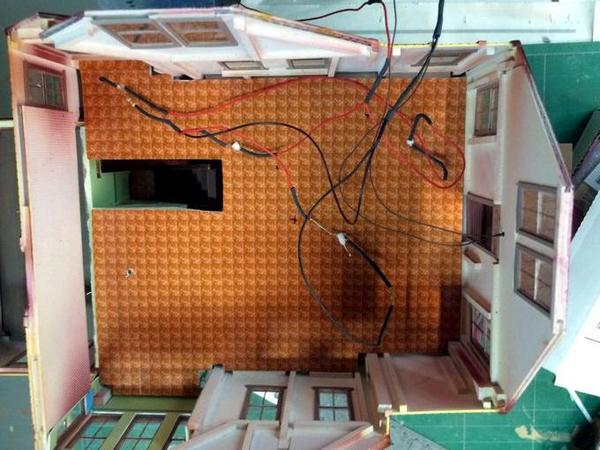

I couldn't help myself... and placed the almost-finished station back on the layout for some progress shots.

We're getting really close now. Tomorrow I'll put on the loading dock, do some weathering, add some exterior accessories (and two downspouts) and folks, and mount it to its base plate and drop it onto the layout. At that point I'm going to start wiring up some DC to get this building illuminated.