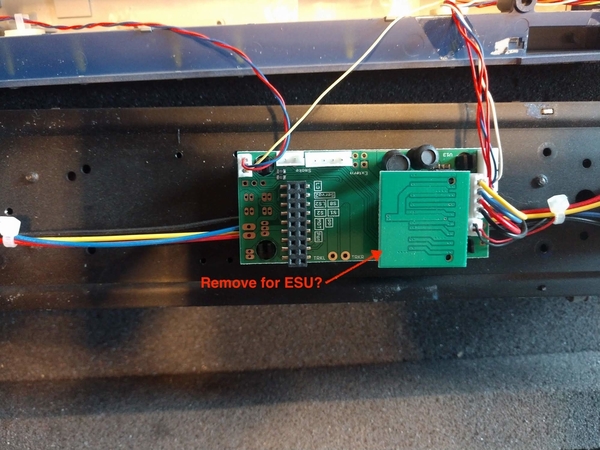

Andy that's good about the decoder.

For your layout, what kind of operations to you want to model? Probably some kind of switching would work well in the space you have.

My preference is for trying to replicate the industrial switching I can railfan around where I live, so that's all I know about.

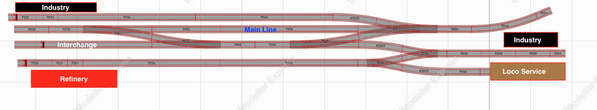

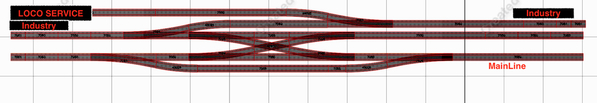

For a shelf layout, switching an industry or two, and an implied connection to "the rest of the world" to receive cars and send them back out might be a starting point. I'll use an example from my layout. It's supposed to be modern era, so I have fewer larger industries, but several car spots.

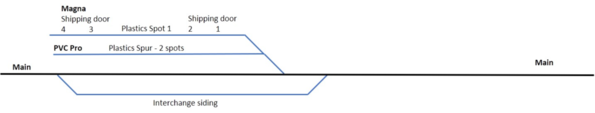

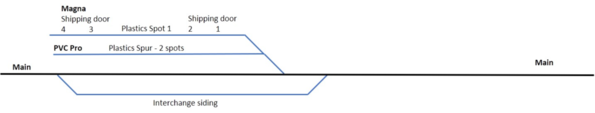

Here's my Magna auto parts plant. It has 2 spurs. One has 4 shipping spots for box cars that are loaded with various parts, and one spot for a hopper that delivers plastic pellets. The second spur has 2 more spots for plastic hopper unloading and one for a chemical tank car unloading for PVC Pro that shares the spur.

There's a main line running by and a siding or interchange track where another "way freight" train (real or imagined) can drop off the cars Magna needs and collect the cars the switcher pulled from Magna yesterday. I'm still modelling plywood season by the way.

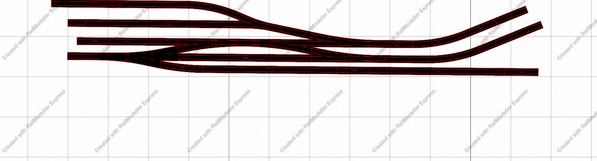

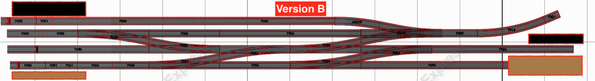

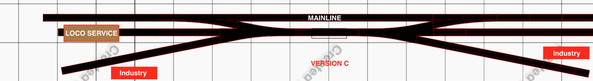

In a shelf layout situation, the cars for today's switching job could already be on the passing siding or interchange track in the foregound. Here's a simplified diagram of Magna (click the attachment for a clearer view) as you might lay it out on a shelf:

You need some headroom on the main to the right so you have enough length to pull and sort cars from Magna and the interchange siding.

The switching job (that's you) would need to pull all the cars that are ready to ship from Magna and replace them with cars from the interchange track. Cars pulled from Magna would be set out in the interchange track ready for the next passing train (imaginary) to lift when it sets out Magna cars for tomorrow.

Might seem a bit quick and easy, but bear in mind that not all Magna dock doors can load a whole car in a day. And not all doors need a car every day. As well some of the plastics hoppers get used as storage and may sit there for several days. So you can make a switchlist that shows some cars to be pulled every day, and some that need to be put back (re-spotted) because they weren't ready yet. The works is a bit different every day.

As well perhaps the passing way freight dropped off more cars than Magna has room for some days, so you'd need to sort out the ones for today from a longer cut of cars in the interchange. You'll find this job can keep you or a 2-person crew busy for up to an hour if you work at scale speeds and have each crew member doing all the real-world work.

I hope this gives a bit of food for thought! You can get a lot of fun out of a fairly simple layout - 4 turnouts and a box of flex track.

![]()