Thanks, that does help! The more I look at the board the more it makes sense. I think. haha

I haven't measured for the speaker yet. Will do that today. I think the smaller one will fit, but will measure. I might buy the larger one and swap it into the CSX and put the smaller one in here. It does have an 8 ohm speaker in it now, but I am sure the quality is not the same.

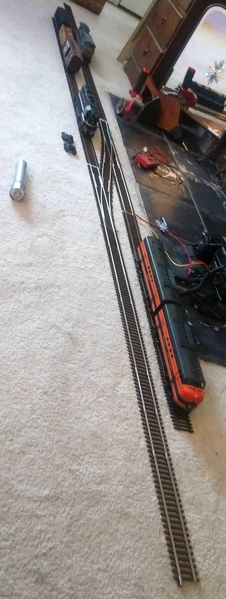

I remembered this morning I have the board from the CSX install since it was DCC ready. So I took a look at it and looked at the ESU install guide. It has the following pad labels I think correspond with what you said...Tell me if I am seeing correctly.

TRK L & TRK R -- Track power (red wires from trucks?) How do I know which is L & R? Black wire on trucks are ground wires and go to the GND pad on board?

MOT + & MOT - -- Motor terminals positive and negative. Is there a way to know which is positive and which is negative for the electrically challenged? Atlas didn't use NMRA standard colors I have yellow and blue.

FL & RL -- Front and rear Light Negative Wire? (should I assume the resistor on the light already is fine? Positive side to U+? There are 2 U+ pads.

AUX 1 & Aux 2 -- front and rear marker lights. (Negative wire) Positive wire to U+

SP+ & SP- -- Speaker positive and negative lead

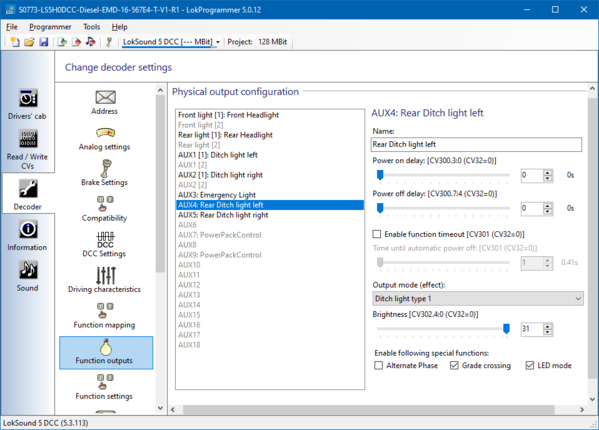

If I wanted to add lighted number boards separately, I can use Aux 3 & 4 and the positive would go to U+ also?

I also assume when I am putting wires together for lights, I solder them together and then have a single lead going to the U+ post?

There is also a potentiometer on the bottom I assume was for sound. I see this board has pads for sound. Any point in using it?