This is the finale of a few posts about my trials and tribulations of converting Rail King passenger cars to LED lighting. Along the way I burned up some electronic components, wired the circuit incorrectly and I had to go back and rework four passenger cars where the LED lighting was way too bright. However, now that I have my act together thanks to a lot of help from Gunrunnerjohn, I and my Z4000 are happy with the result.

Although the technique in this post is demonstrated on a Rail King passenger car, the circuit and technique are suitable for other brands of trains.

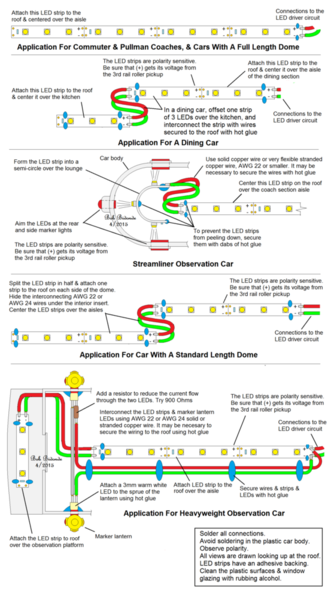

Several threads down I have posted a sketch of the general arrangements of components I have arrived at having completed 15 conversions.

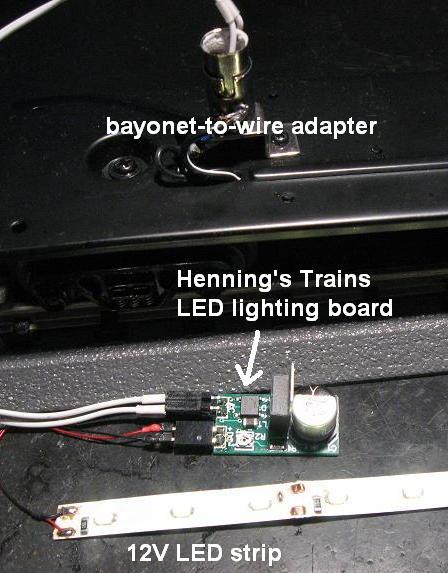

From L to R: 22 uH Induction Coil; DF005 Bridge Rectifier; 470 uF 35V Capacitor; LM317 Regulator;

100 Ohm 1/2W Resistor. A 470 uF 50V Capacitor is more robust.

There is a MS Word file below that explains the conversion to LEDs. What is shown in this post applies to cabooses and other rolling stock. However, this is not for powered units with DCS, TMCC and Legacy command controls.