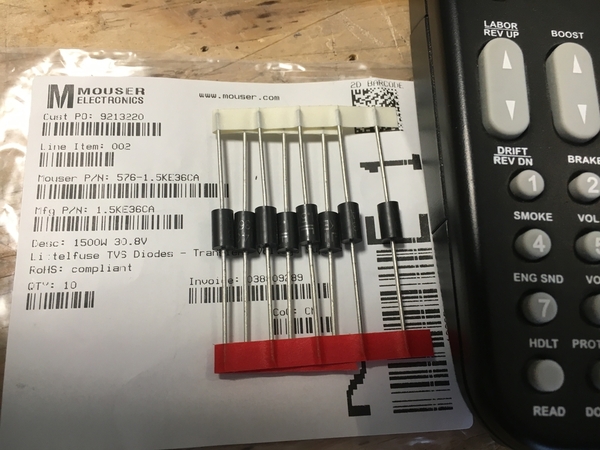

Michael, Yes I was not familiar with TVS diodes until I saw they were recommended as protection for engines with modern electronics. That was only about 5 years ago. I am curious, but have never taken the time to look up their electrical properties, but this discussion has reinforced my need to look that up. Maybe after Christmas I'll get to that.

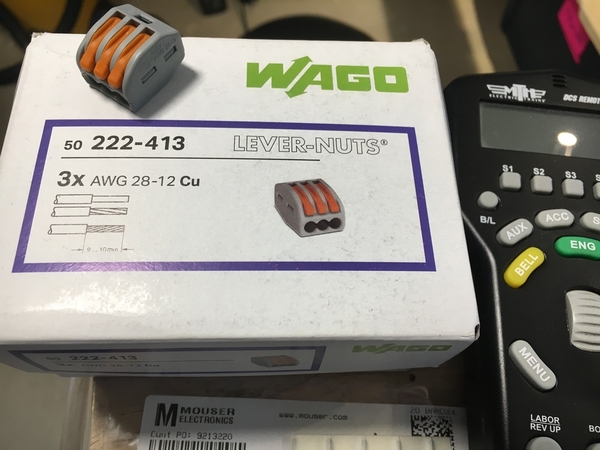

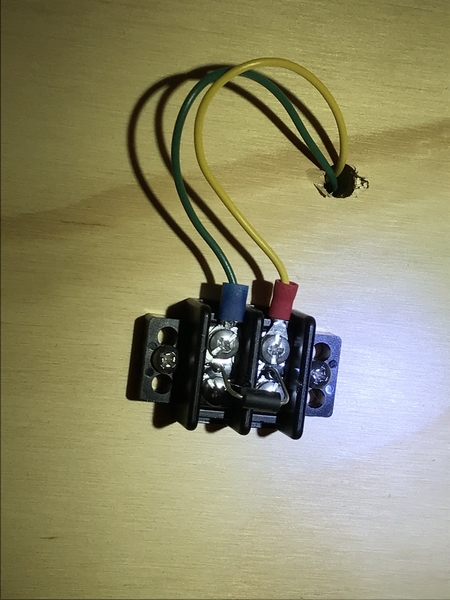

For this layout, I used the GarGraves rail pins with feeder wires already soldered on. Maybe the easy way out, but things are getting harder for me to do, and soldering is one of them. I forget, they may be #18 wire. I went with the Wago lever connectors (the ones that handle 3 wires) that many Forum member recommended. I like them. They are a bit stiff to lift the lever the first time, but they really grip almost any size wire we would use on the layout. I have #12 wire feeding from the MTH terminals at the panel to the Wago in the star configuration. Funny, at the telephone company, we called it star configuration for Ethernet, but home run for telephone. I am going to try to add the TVS to the Wago connectors. There is a empty hole in all the hot feeds, but I put in a drop for both outer rails, using up the three holes. I will try adding that end of the TVS as a second 'wire' in one of the holes on the Wago, and really tug hard to make sure the connection is good. I may have to buy the 5 hole Wagos and refit the outer rail connectors. It isn't a problem. They are really easy to open and switch out. I like them so much better than terminal blocks and fooling with tightening them down under the layout, although I can reach many of them from the top. I hope this works.

If not, I intend to buy more Wagos for my DZ1000 switch machines since they have feeder wires on them. I don't see a need for TVS there. I never heard of anyone doing that. I think accessories and lighting can be done in a bus fashion. We aren't worried about signal strength and all those issues with DCS.

I acquired things from my dad too. I got a lot of lumber from my dad's shop when we cleaned everything out last year before selling. Mum and Dad (both 90) have been living in a personal care home for 3 years. It just took us a couple years to figure out no family member was in the position to take the old 1888 homestead on. I'm using some of my dad's tools also. When he bought a new tool, he told me I could borrow it any time, and they would be mine when he didn't need them any more. My brother is a renter and not handy with tools. Dad had a lot of Grandpa's tools, but they are cumbersome and I let them go with the house. Grandpa passed on in 1956, the year I was born.